MAN B&W 8.08

Page 1 of 1

MAN Diesel

MAN B&W ME/MEC/MEGI/ME-B engines

ME Engine Selection Guide

198 48 297.3

Hydraulic Oil Backflushing

The special suction arrangement for purifier suc-

tion in connection with the ME engine (Integrated

system).

The back-flushing oil from the self cleaning 6 µm

hydraulic control oil filter unit built onto the engine

is contaminated and it is therefore not expedient to

lead it directly into the lubricating oil sump tank.

The amount of back-flushed oil is large, and it

is considered to be too expensive to discard

it. Therefore, we suggest that the lubricating

oil sump tank is modified for the ME engines in

order not to have this contaminated lubricating

hydraulic control oil mixed up in the total amount

of lubricating oil. The lubricating oil sump tank is

designed with a small ‘back-flushing hydraulic

control oil drain tank’ to which the back-flushed

hydraulic control oil is led and from which the lu-

bricating oil purifier can also suck.

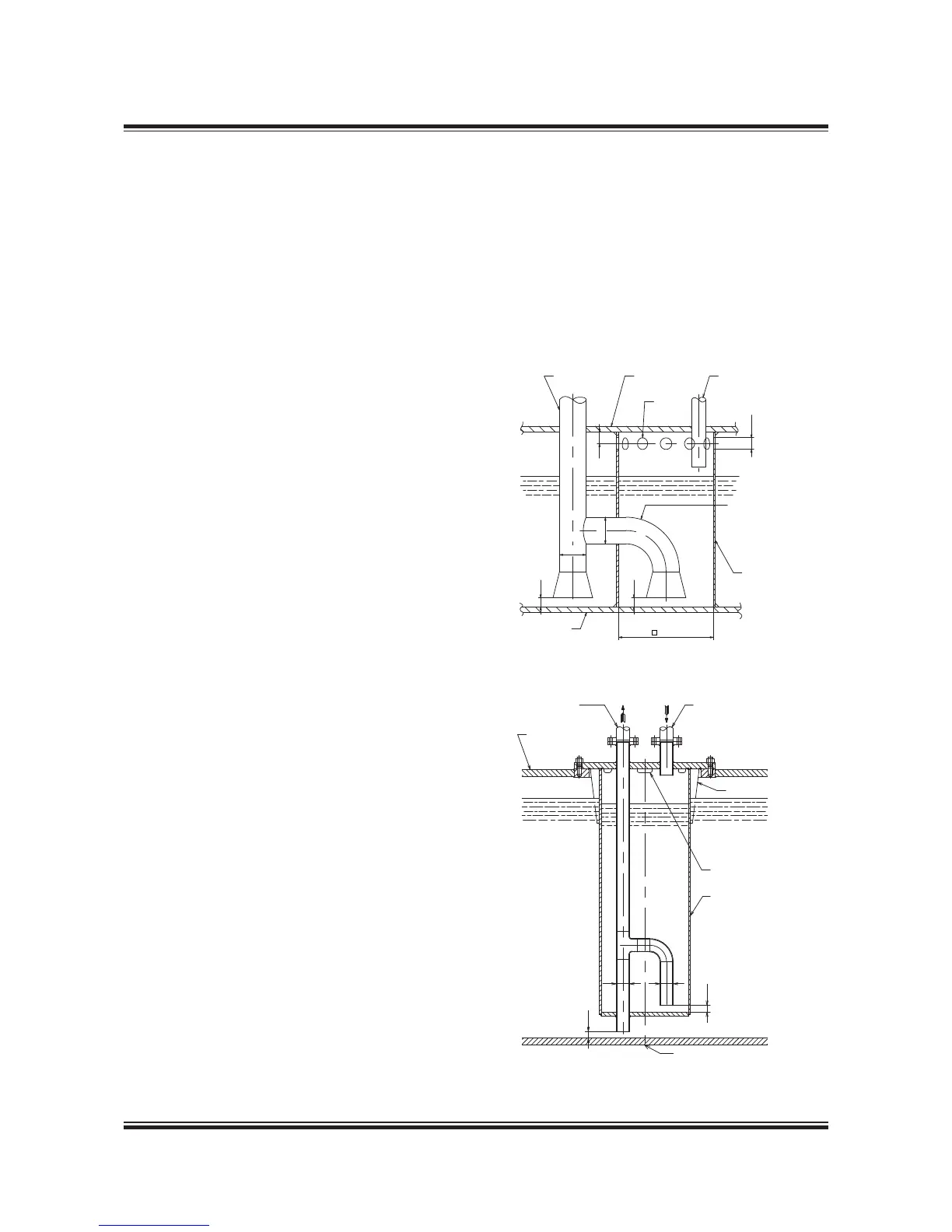

This is explained in detail below and the principle

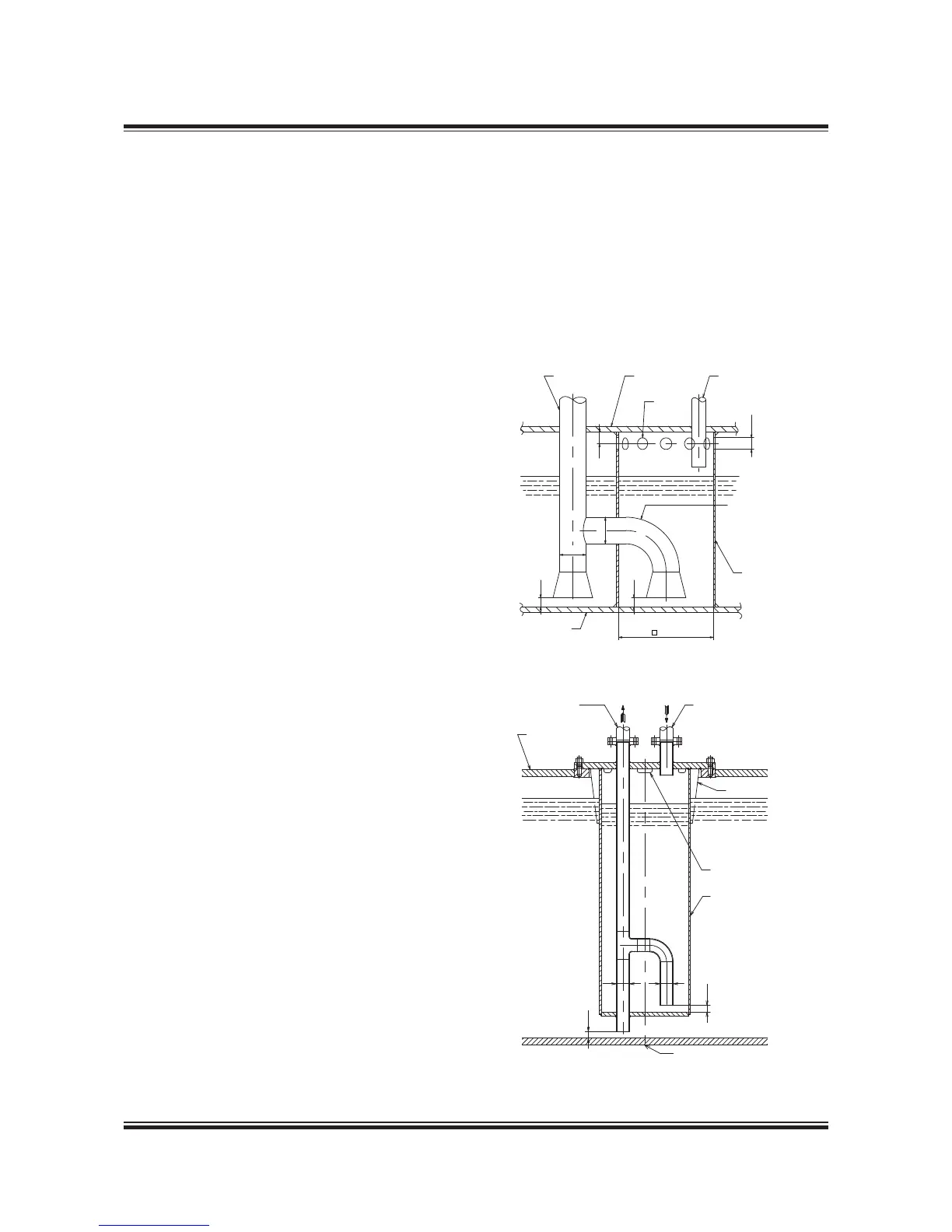

is shown in Fig. 8.08.01. Three suggestions for the

arrangement of the drain tank in the sump tank

are shown in Fig. 8.08.02 illustrates another sug-

gestion for a back-flushing oil drain tank.

The special suction arrangement for the purifier is

consisting of two connected tanks (lubricating oil

sump tank and back-flushing oil drain tank) and

of this reason the oil level will be the same in both

tanks, as explained in detail below.

The oil level in the two tanks will be equalizing

through the ‘branch pipe to back-flushing oil drain

tank’, see Fig. 8.08.01. As the pipes have the

same diameters but a different length, the resis-

tance is larger in the ‘branch pipe to back-flushing

oil drain tank’, and therefore the purifier will suck

primarily from the sump tank.

The oil level in the sump tank and the back-flush-

ing oil drain tank will remain to be about equal be-

cause the tanks are interconnected at the top.

When hydraulic control oil is back-flushed from

the filter, it will give a higher oil level in the back-

flushing hydraulic control oil drain tank and the

purifier will suck from this tank until the oil level is

the same in both tanks. After that, the purifier will

suck from the sump tank, as mentioned above.

Fig. 8.08.01: Backflushing servo oil drain tank

178 52 518.2

Fig. 8.08.02: Alternative design for the

backflushing servo oil drain tank

178 52 496.2

This special arrangement for purifier suction will

ensure that a good cleaning effect on the lubrica-

tion oil is obtained.

If found profitable the back-flushed lubricating oil

from the main lubricating oil filter (normally a 50 or

40 µm filter) can also be returned into the special

back-flushing oil drain tank.

Oil level

50

D/3

D

8XØ50

D/3

D

Purifier

suction pipe

Lubricating

oil tank top

Venting

holes

Backflushed hydraulic

control oil from self

cleaning 6 µm filter

Branch pipe to

backflushing

hydraulic control

oil drain tank

Sump

tank

Backflushing

hydraulic control

oil drain tank

Pipe ø400

or 400

Lubricating

oil tank bottom

Oil level

Support

Venting holes

D D

D/3

D/3

Purifier

suction pipe

Lubricating

oil tank top

Backflushed hydraulic

controloil from self

cleaning 6 µm filter

Sump

tank

Backflushing

hydraulic control

oil drain tank

Loading...

Loading...