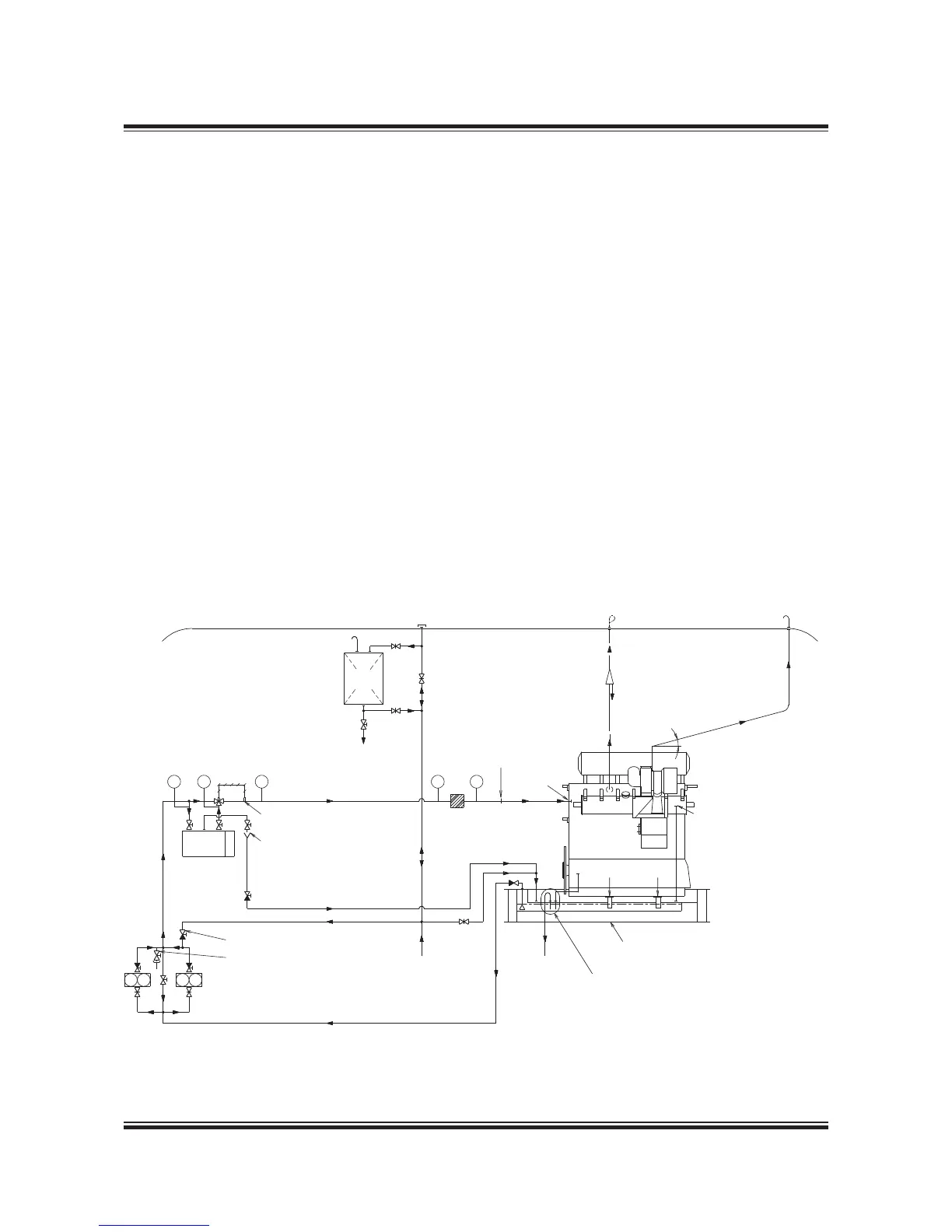

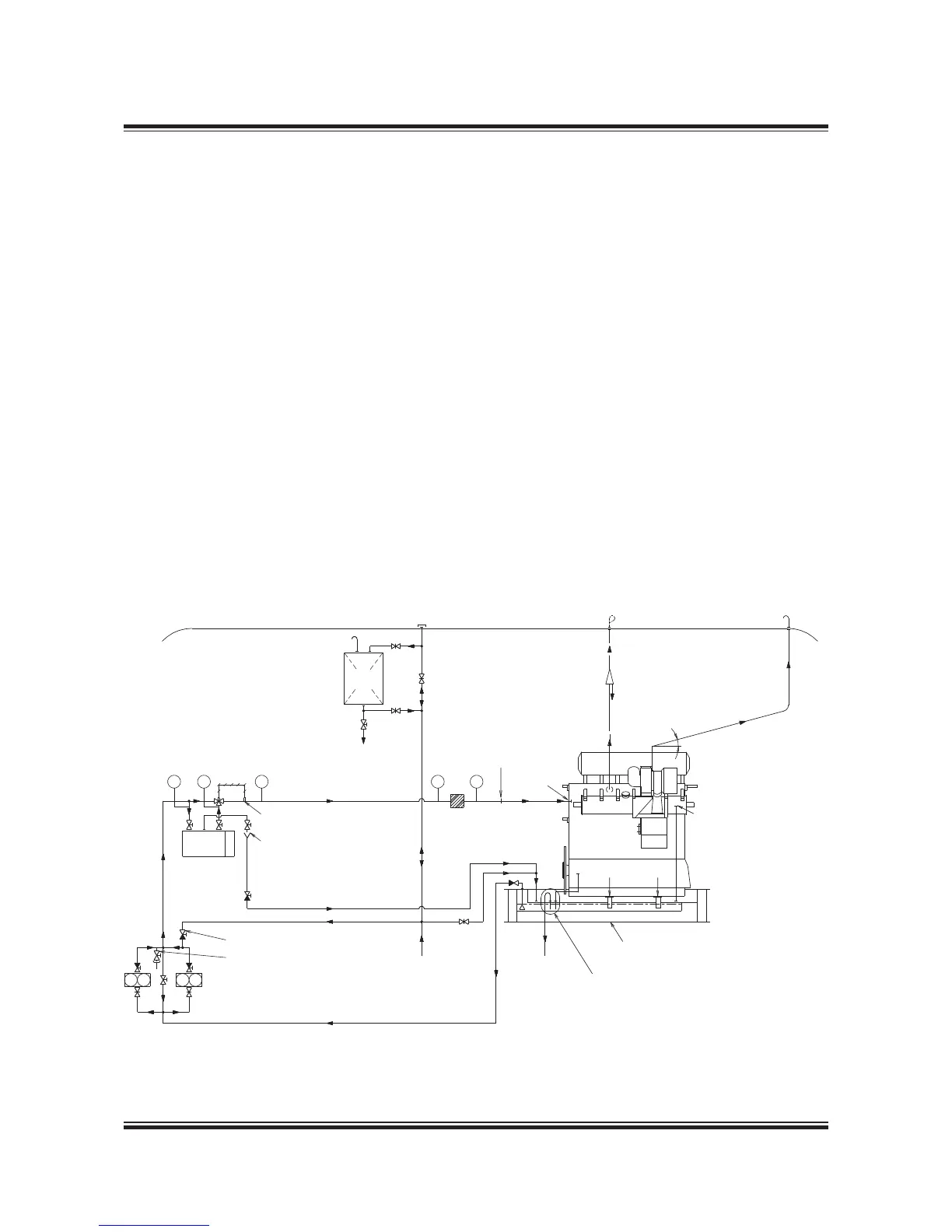

Lubricating and Cooling Oil System

Thermostatic valve

TI TI TI

Lube. oil

cooler

For initial fillling of pumps

Pos. 006: 25 mm valve

for cleaning process

Lube oil pumps

Engine

oil

PI PI

Fullflow filter

RU

AR

E

AB

Min. 15°

Lube oil bottom tank

with cofferdam

To purifier

From purifier

Deck

To drain tank

Pos. 005: throttle valve

Deaeration

Feeler, 45 °C

*

S S

Servo oil backflushing

see Section 8.08

RW

The letters refer to list of ‘Counterflanges’

* Venting for MAN Diesel or Mitsubishi turbochargers only

198 99 844.5

The lubricating oil is pumped from a bottom tank

by means of the main lubricating oil pump to the

lubricating oil cooler, a thermostatic valve and,

through a fullflow filter, to the engine inlet RU, Fig.

8.01.01.

RU lubricates main bearings, thrust bearing, axial

vibration damper, piston cooling, crosshead bear-

ings, crankpin bearings. It also supplies oil to the

Hydraulic Power Supply unit and to the torsional

vibration damper.

From the engine, the oil collects in the oil pan,

from where it is drained off to the bottom tank,

see Fig. 8.06.01a and b ‘Lubricating oil tank, with

cofferdam’. By class demand, a cofferdam must

be placed underneath the lubricating oil tank.

The engine crankcase is vented through ‘AR’ by a

pipe which extends directly to the deck. This pipe

has a drain arrangement so that oil condensed in

the pipe can be led to a drain tank, see details in

Fig. 8.07.01.

Drains from the engine bedplate ‘AE’ are fitted on

both sides, see Fig. 8.07.02 ‘Bedplate drain pipes’.

For external pipe connections, we prescribe a

maximum oil velocity of 1.8 m/s.

Lubrication of turbochargers

Turbochargers with slide bearings are normally

lubricated from the main engine system. AB is

outlet from the turbocharger, see Figs. 8.03.01 to

8.03.04.

Figs. 8.03.01 to 8.03.04 show the lube oil pipe ar-

rangements for different turbocharger makes.

Fig. 8.01.01 Lubricating and cooling oil system

Loading...

Loading...