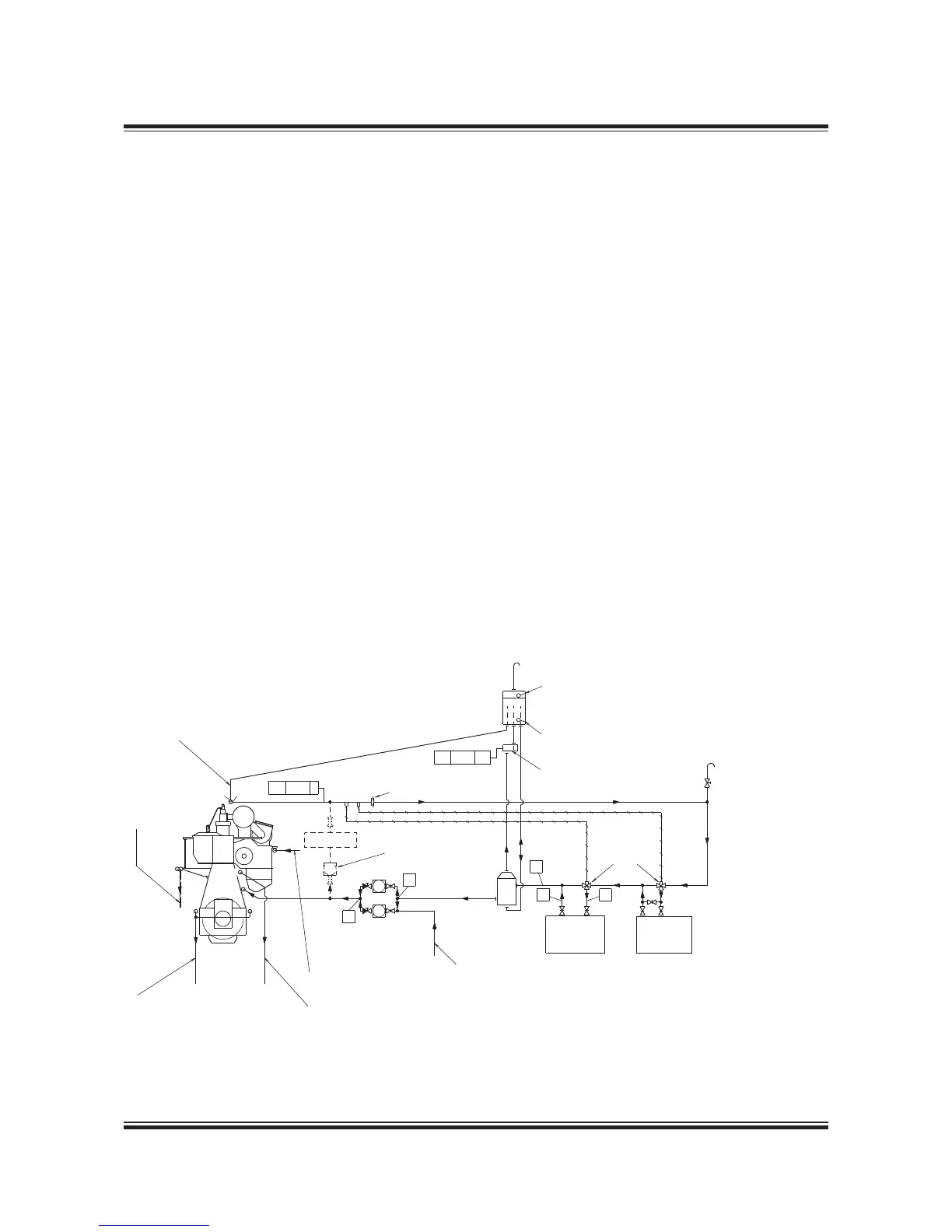

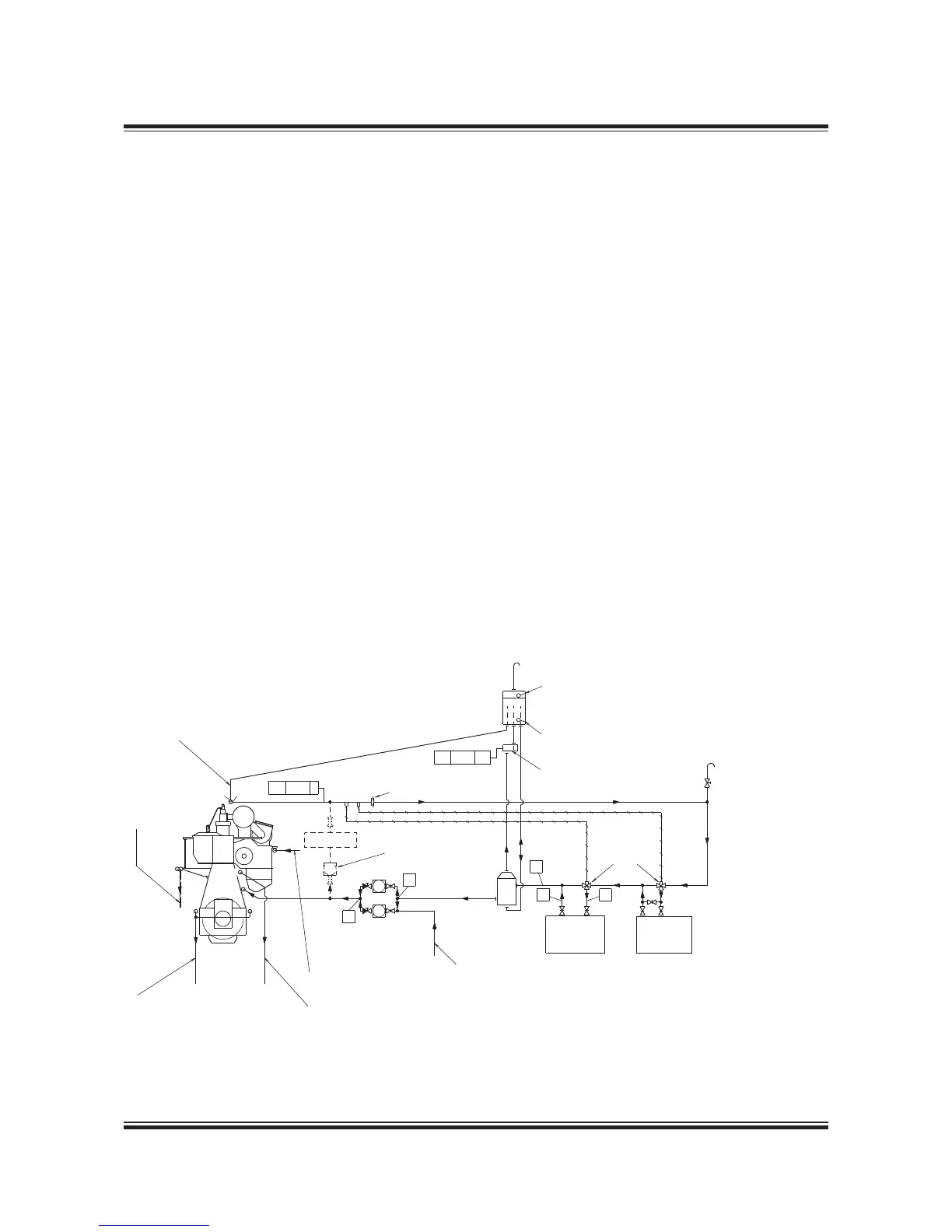

Expansion tank

Low level alarm

Alarm device box,

see Fig. 12.07.02

Normally closed valve.

To be opened when the

system is filled with

cooling water. (Manually

or automatically)

Freshwater

generator

Jacket water

cooler

Deaerating tank,

see Fig. 12.07.01

From tracing of fuel oil drain pipe

High level alarm

Regulating

valve

Preheater pump

Jacket Cooling Water System

The jacket cooling water system is used for cool-

ing the cylinder liners, cylinder covers and exhaust

valves of the main engine and heating of the fuel

oil drain pipes, see Fig. 12.05.01.

The jacket water pump draws water from the

jacket water cooler outlet and delivers it to the

engine.

At the inlet to the jacket water cooler there is a

thermostatically controlled regulating valve, with

a sensor at the engine cooling water outlet, which

keeps the main engine cooling water outlet at a

temperature between 88 and 92 °C.

The engine jacket water must be carefully treated,

maintained and monitored so as to avoid corro-

sion, corrosion fatigue, cavitation and scale for-

mation. It is recommended to install a preheater

if preheating is not available from the auxiliary

engines jacket cooling water system.

The venting pipe in the expansion tank should end

just below the lowest water level, and the expan-

sion tank must be located at least 15 m above the

top of the exhaust valves.

The freshwater generator, if installed, may be con-

nected to the seawater system if the generator

does not have a separate cooling water pump.

The generator must be coupled in and out slowly

over a period of at least 3 minutes.

In case it is possible to utilise more than 50% of

the heat available, we recommend to install a ther-

mostatic valve at the freshwater generator inlet,

adjusted to keep a minimum cooling water outlet

temperature of 88 °C.

For external pipe connections, we prescribe the

following maximum water velocities:

Jacket water ................................................ 3.0 m/s

Seawater ..................................................... 3.0 m/s

Fig. 12.05.01: Jacket cooling water system

078 70 71-7.0.1

The letters refer to list of ‘Counterflanges’

Loading...

Loading...