MAN Diesel

MAN B&W S50MEC, G50ME-B, S50ME-B, S46ME-B,

S40ME-B, G40ME-B, S35ME-B, S30ME-B

198 76 610.4

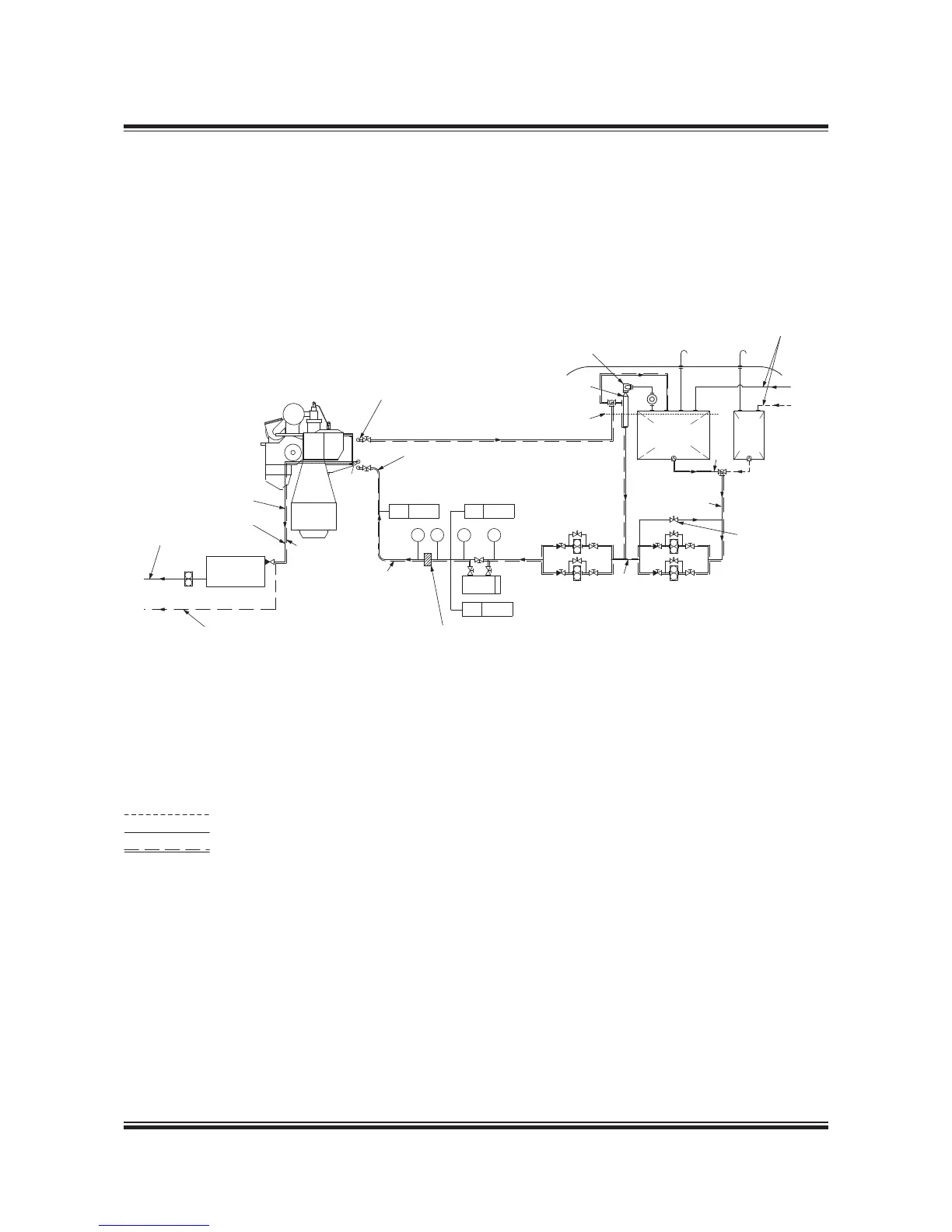

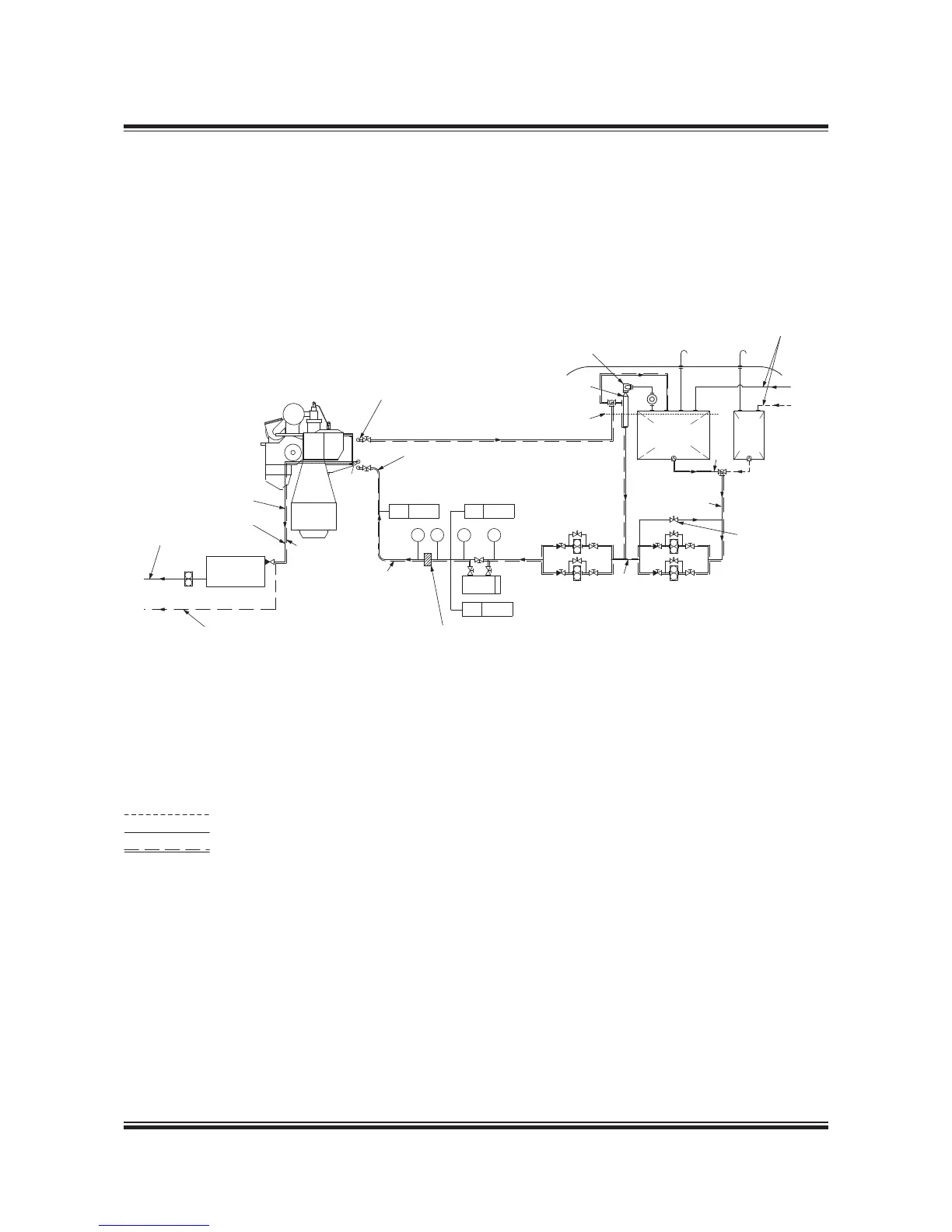

Fuel Oil System

Fig. 7.01.01: Fuel oil system

078 70 06-1.1.0a

Diesel oil

Heavy fuel oil

Heated pipe with insulation

a) Tracing fuel oil lines: Max.150°C

b) Tracing drain lines: By jacket cooling water

The letters refer to the list of ‘Counterflanges’

Deck

PI TI

Heater

PI TI

From centrifuges

Circulating pumps Supply pumps

D* )

d* )

D* )

32 mm Nominal bore

Aut. deaerating valve

Top of fuel oil service tank

Venting tank

Arr. of main engine fuel oil system.

(See Fig. 7.03.01)

F

X

AF

#

)

b)

a)

BD

To storage/settling tank

To freshwater cooling pump suction

To drain tank

Fuel oil

drain tank

If the fuel oil pipe to engine is made as a straight line

immediately before the engine, it will be necessary to

mount an expansion unit. If the connection is made

as indicated, with a bend immediately before the

engine, no expansion unit is required.

Full flow filter.

For filter type see engine spec.

Overflow valve

Adjusted to 4 bar

Heavy fuel oil

service tank

Diesel

oil

service

tank

TE 8005

#) Approximately the following quantity of fuel oil should be treated in

the centrifuges: 0.23 l/kwh as explained in Section 7.05. The capacity of

the centrifuges to be according to manufacturer’s recommendation.

* ) D to have min. 50% larger passage area than d.

PT 8002

VT 8004

Loading...

Loading...