MAN B&W 8.05

Page 3 of 5

MAN Diesel

MAN B&W ME/ME-C/ME-B/-GI engines 198 80 26-6.0

Flushing of lubricating oil components and

piping system at the shipyard

During installation of the lubricating oil system

for the main engine, it is important to minimise or

eliminate foreign particles in the system. This is

done as a final step onboard the vessel by flush-

ing the lubricating oil components and piping

system of the MAN B&W main engine types ME/

ME-C/ME-B/-GI before starting the engine.

At the shipyard, the following main points should

be observed during handling and flushing of the

lubricating oil components and piping system:

• Before and during installation

Components delivered from subsuppliers, such

as pumps, coolers and filters, are expected to

be clean and rust protected. However, these

must be spot-checked before being connected

to the piping system.

All piping must be ‘finished’ in the workshop

before mounting onboard, i.e. all internal welds

must be ground and piping must be acid-treat-

ed followed by neutralisation, cleaned and cor-

rosion protected.

Both ends of all pipes must be closed/sealed

during transport.

Before final installation, carefully check the in-

side of the pipes for rust and other kinds of for-

eign particles.

Never leave a pipe end uncovered during as-

sembly.

• Bunkering and filling the system

Tanks must be cleaned manually and inspected

before filling with oil.

When filling the oil system, MAN Diesel & Turbo

recommends that new oil is bunkered through 6

μm fine filters, or that a purifier system is used.

New oil is normally delivered with a cleanliness

level of XX/23/19 according to ISO 4406 and,

therefore, requires further cleaning to meet our

specification.

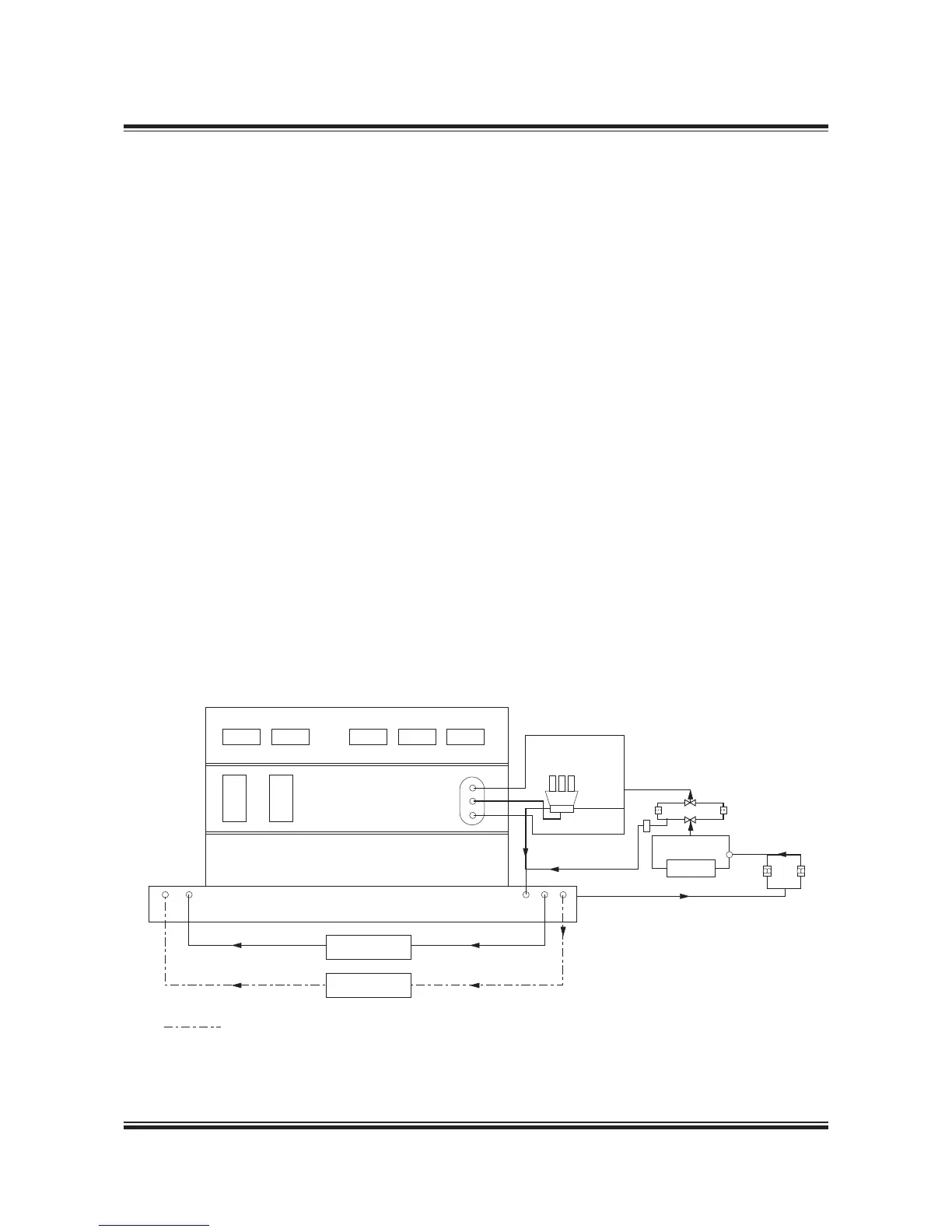

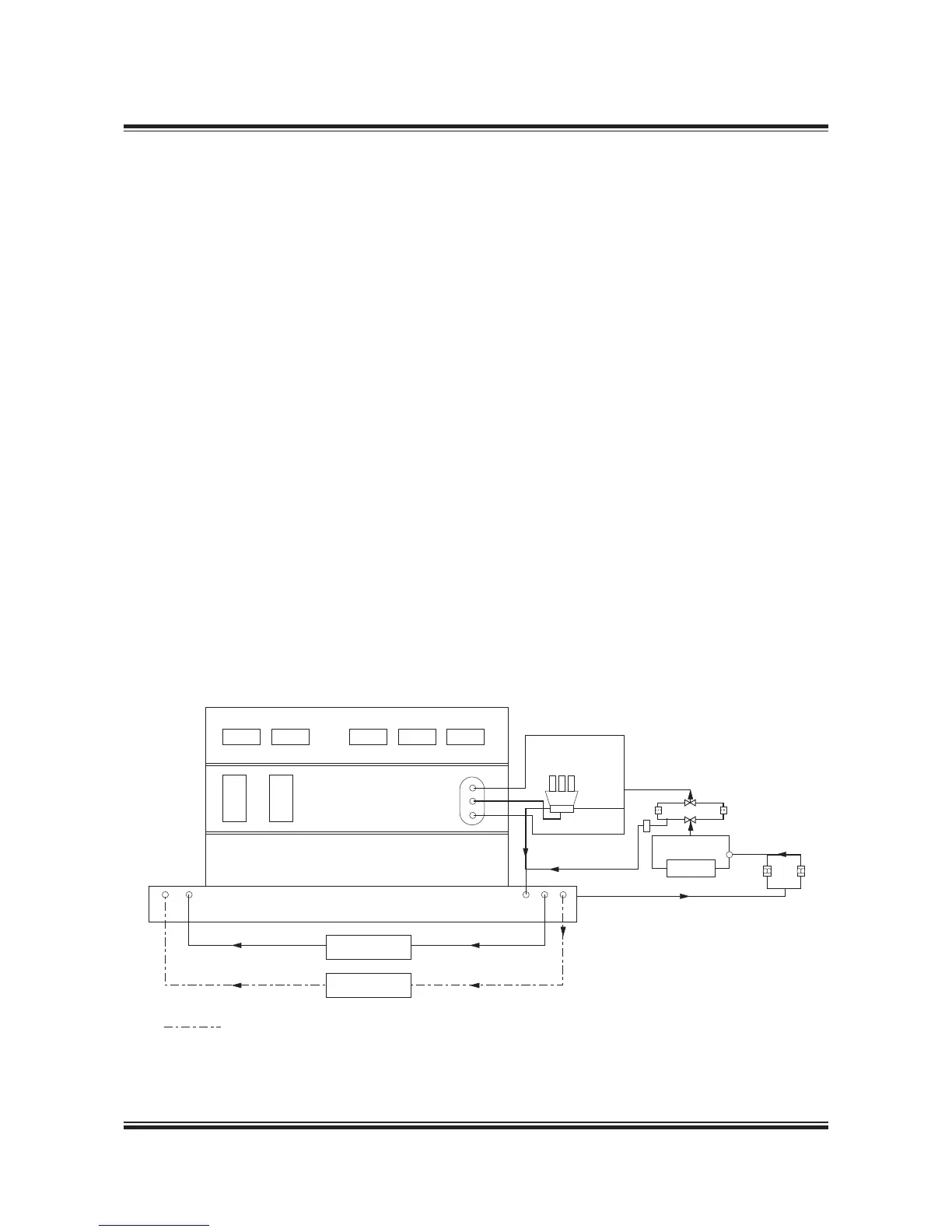

• Flushing the piping with engine bypass

When flushing the system, the first step is to by-

pass the main engine oil system. Through tem-

porary piping and/or hosing, the oil is circulated

through the vessel’s system and directly back to

the main engine oil sump tank.

Fig. 8.05.01: Lubricating oil system with temporary hosing/piping for flushing at the shipyard

Purifier

Tank sump

6 µm Filter unit

Cooler

Pumps

Filter unit

Temporary hosing/piping

610 µm

Autofilter

Back flush

178 61 99-7.0

Loading...

Loading...