Maintenance work on the superstructure

8.6 Hoists

8 - 46 3 302 577 en Maintenance manual

GMK7450

16.08.2018

8.6.5 Changing the oil/checking the oil

•

Also adhere to the à Run-in regulations, P. 4 - 1.

Oil, spare parts,

tools

– Receptacle, approx. 12 l (3.2 gal);

à P. 2 - 4.

– Torque wrench for torque of 30 Nm (22.1 lbf ft).

Prerequisites – The truck crane must be level and in on-road mode;

à Operating manual.

– The auxiliary hoist (additional equipment) is rigged;

à Operating manual.

– The engine must not be running and must be secured against unauthor-

ised use;

à P. 2 - 3.

Changing the oil at

the hoist

H

During filling, the oil spreads only slowly in the hoist. The oil level therefore

rises quickly in the standpipe at first, then drops slightly and then eventually

rises again to its true level.

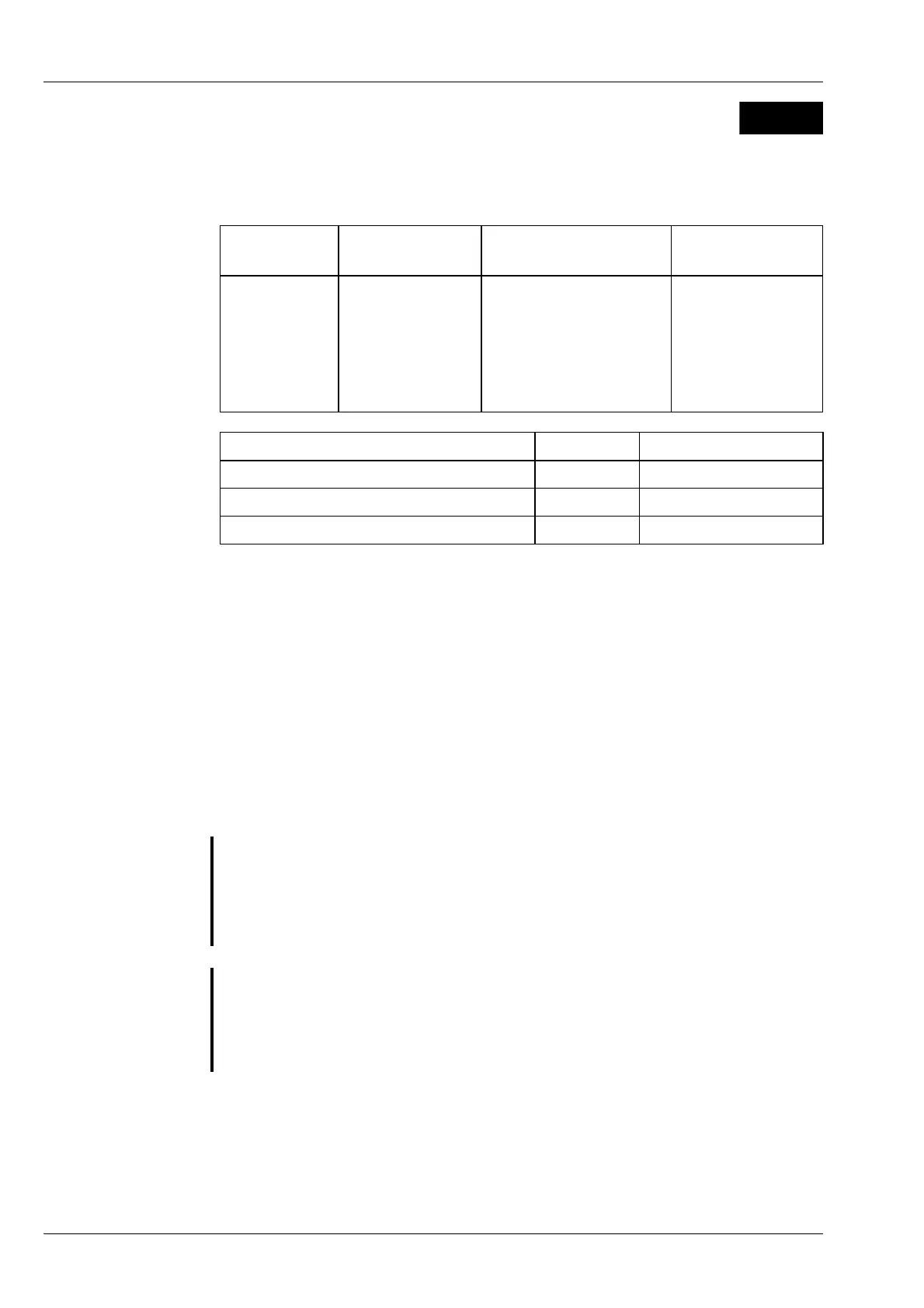

Gear oil

in litres (gal)

Designation

to DIN 51502

Specifications

Classification

GROVE part no.

11.5 (3.0)

for each hoist

C - LPF MIL-L 2105 B

API-GL-4/5

Viscosity:

SAE 75 W-90 EP

I

SO - VG 220

02313611

Synthetic oil; do

not mix this with

mineral-based

oils!

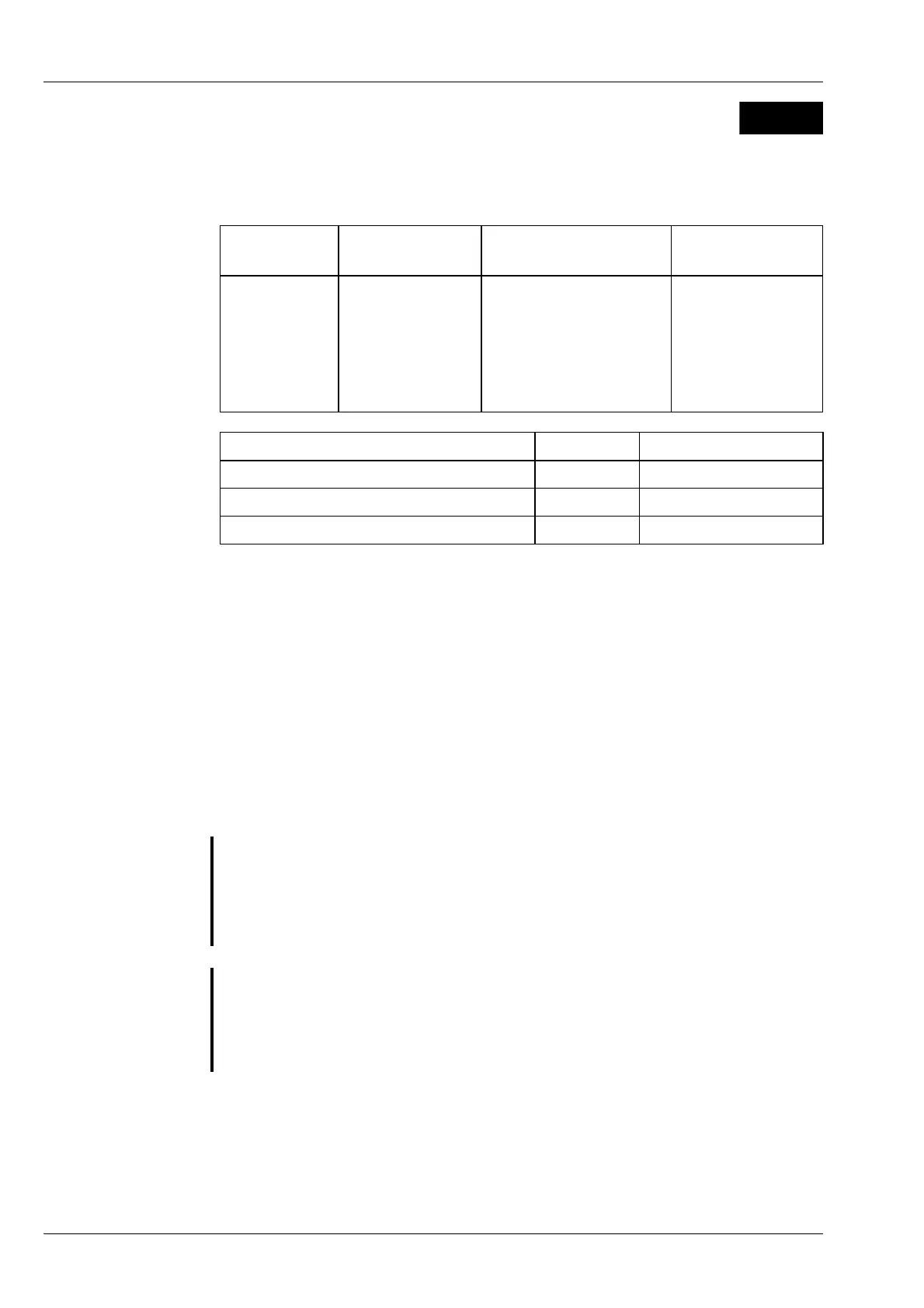

Designation Quantity GROVE part no.

Gasket 14 x 18 Cu DIN 7603 2 00117131

Gasket 18 x 22 Cu DIN 7603 4 00117137

Gasket 26 x 31 Cu DIN 7603 4 00117147

S

Risk of damage to the hoist gears!

The waste oil must be checked for abrasion particles. This inspection is

used to detect any damage

at an early stage;

à P. 8 - 47.

O

Risk of environmental damage due to leaking consumables!

Always let consumables drain into suitable receptacles. Wipe up any con-

sumables that escape.

Store/dispose of consumables and any soaked equipment properly.

Ask about the applicable regulations.

Loading...

Loading...