Maintenance work on the superstructure

8.11 Main boom

16.08.2018

Maintenance manual 3 302 577 en 8 - 89

GMK7450

8.11.3 Lubricating the telescopic slide faces

Reducing the

interval

Under difficult operating conditions – at extremely sandy or rainy locations –

you must lubricate them more frequently.

Grease, spare

parts, tools

– A grease gun for the grease nipples on the upper telescopic slide faces.

– A brush or roller for the outer, upper and lower telescopic slide faces.

H

Manitowoc Crane Group Germany GmbH recommends using pneumatic

grease spray guns for more effective lubrication of the telescopic slide

faces:

Prerequisites – The truck crane is supported on an outrigger span of 8.76 m

x 6.10

m

(28.7 ft x 20

.0 ft) and has been rigged with at least a 60 t counterweight

or

– The

truck crane is supported on an outrigger span of 8.76 m x 8.90 m

(28.7 ft x 29

.2 ft) and has been rigged with at least a 40 t counterweight.

– The

truck crane must be level.

– The hook block must be unreeved.

– The main boom must be completely retracted and lowered into horizontal

position.

– The RCL code for the current rigging mode must be entered.

s

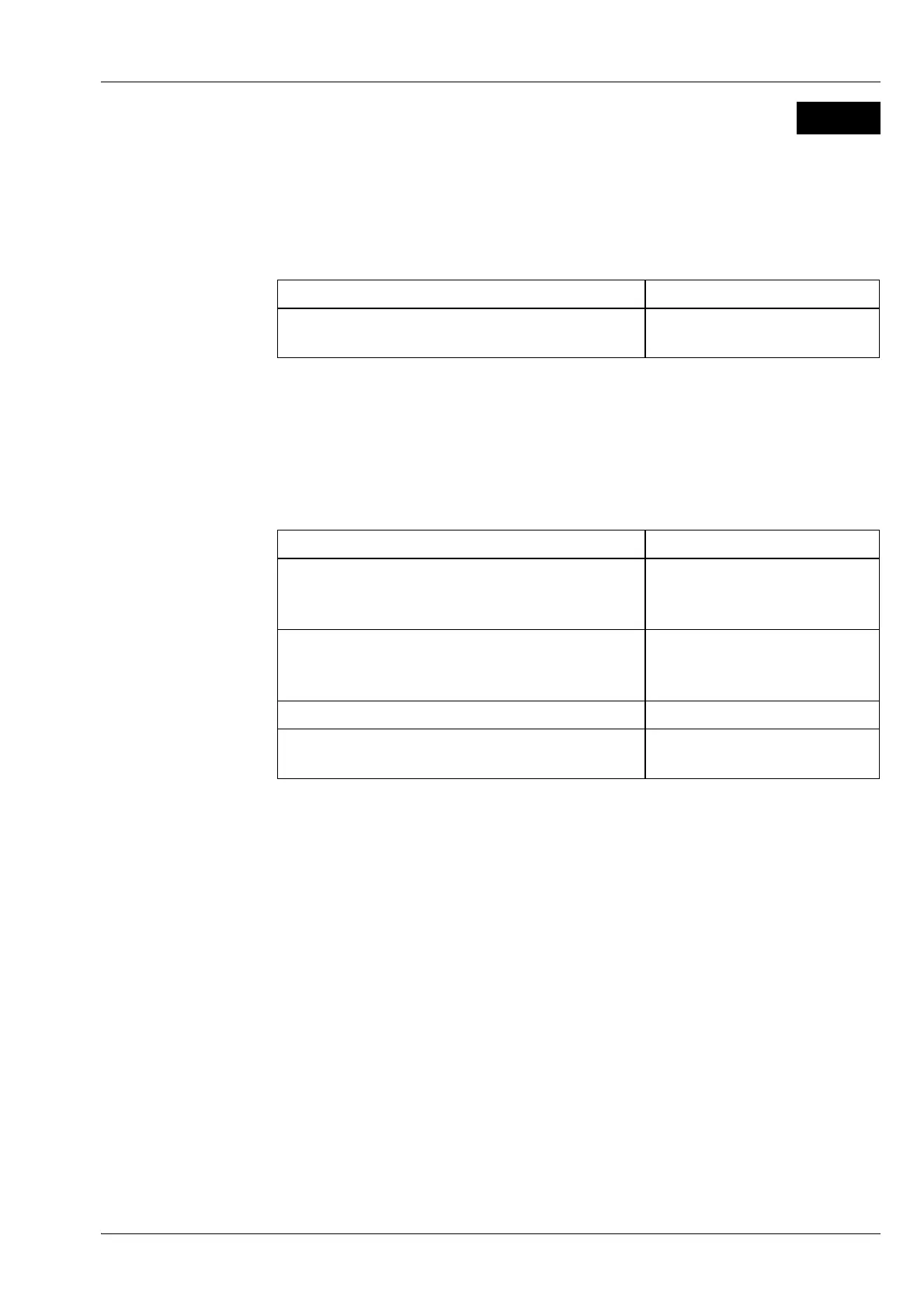

Designation GROVE part no.

Slide paste for the telescopic slide faces:

PAL1, 25 kg bucket

02314698

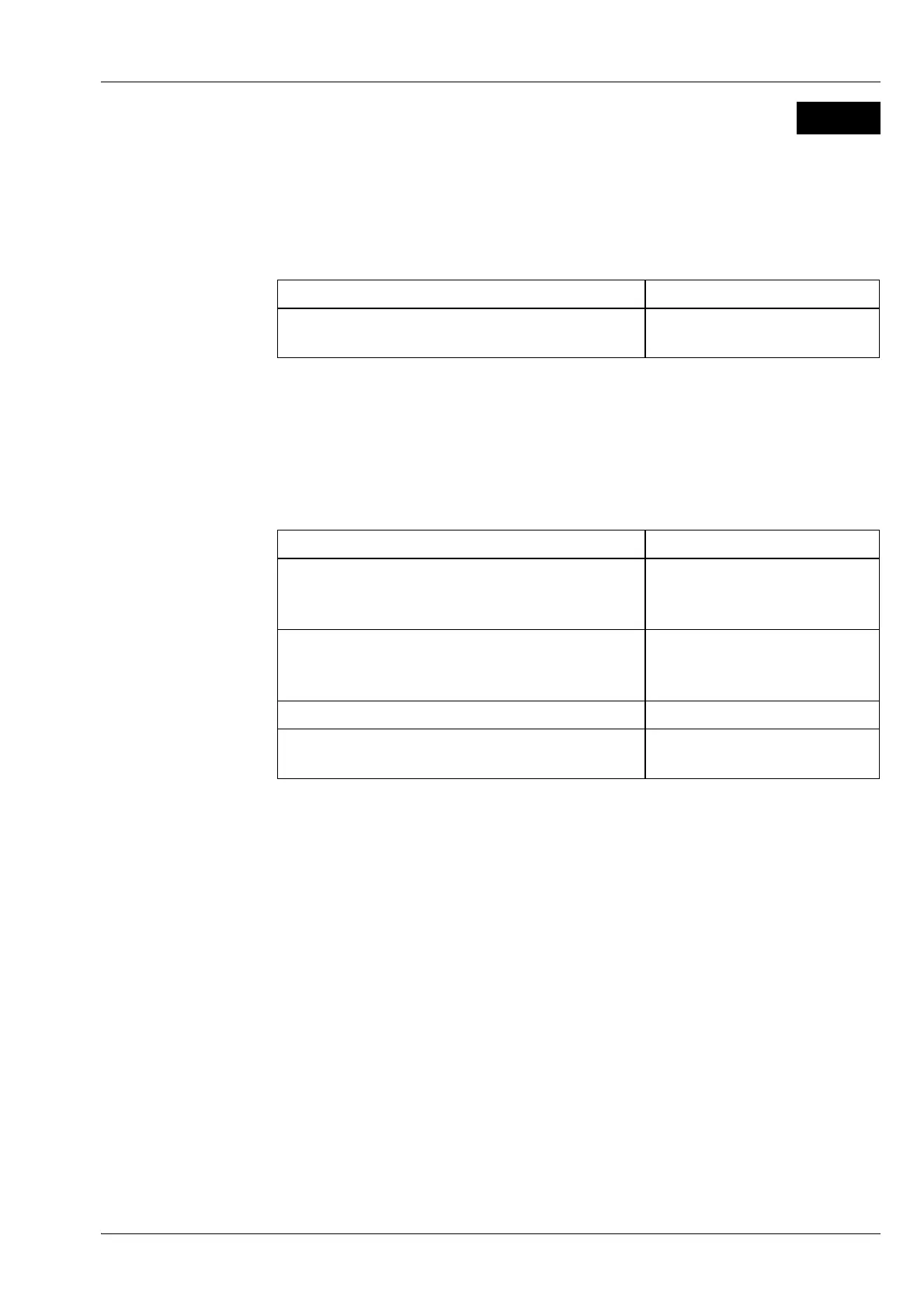

Designation GROVE part no.

Grease spray gun, complete:

Mobile, external compressed air connection

required

03325445

Manual grease spray gun for cartridge:

Via the tyre inflator connection on the truck

crane

03329027

25 m hose for manual grease spray gun: 03329072

Slide paste for the telescopic slide faces:

PAL1, 400 ml cartridge, refillable

03329071

Loading...

Loading...