COMPONENTS

SERVICE-POWER WINDOW/3-POINT ELR SEAT

BELTS WITH TENSION RELIEFERS

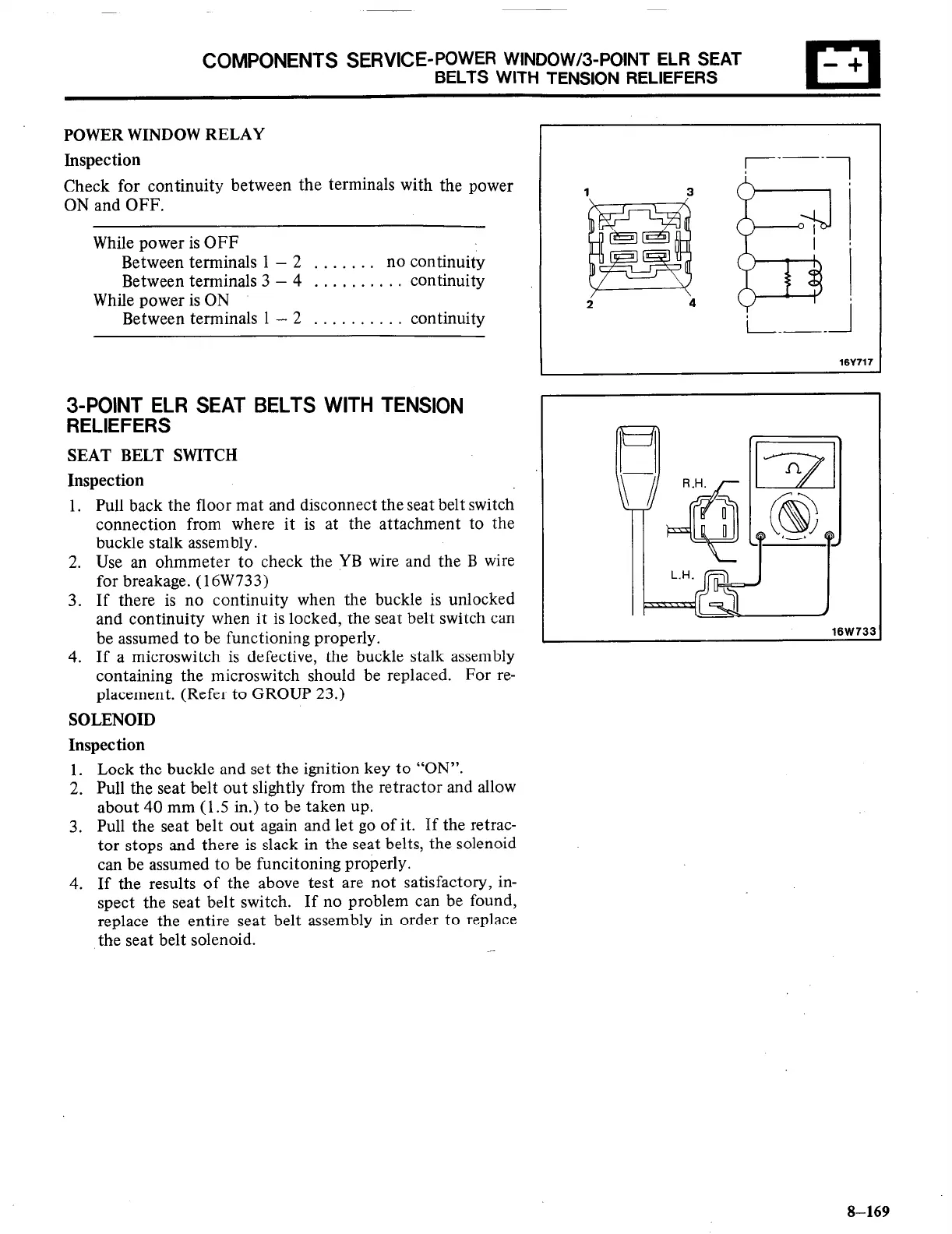

POWER WINDOW RELAY

Inspection

Check for continuity between the terminals with the power

ON and OFF.

While power is OFF

Between terminals 1 - 2 . . . . . . . no continuity

Between terminals 3 - 4 . . . , . . , . . . continuity

While power is ON

Between terminals 1 - 2 . . . . . . . . . . continuity

3-POINT ELR SEAT BELTS WITH TENSION

RELIEFERS

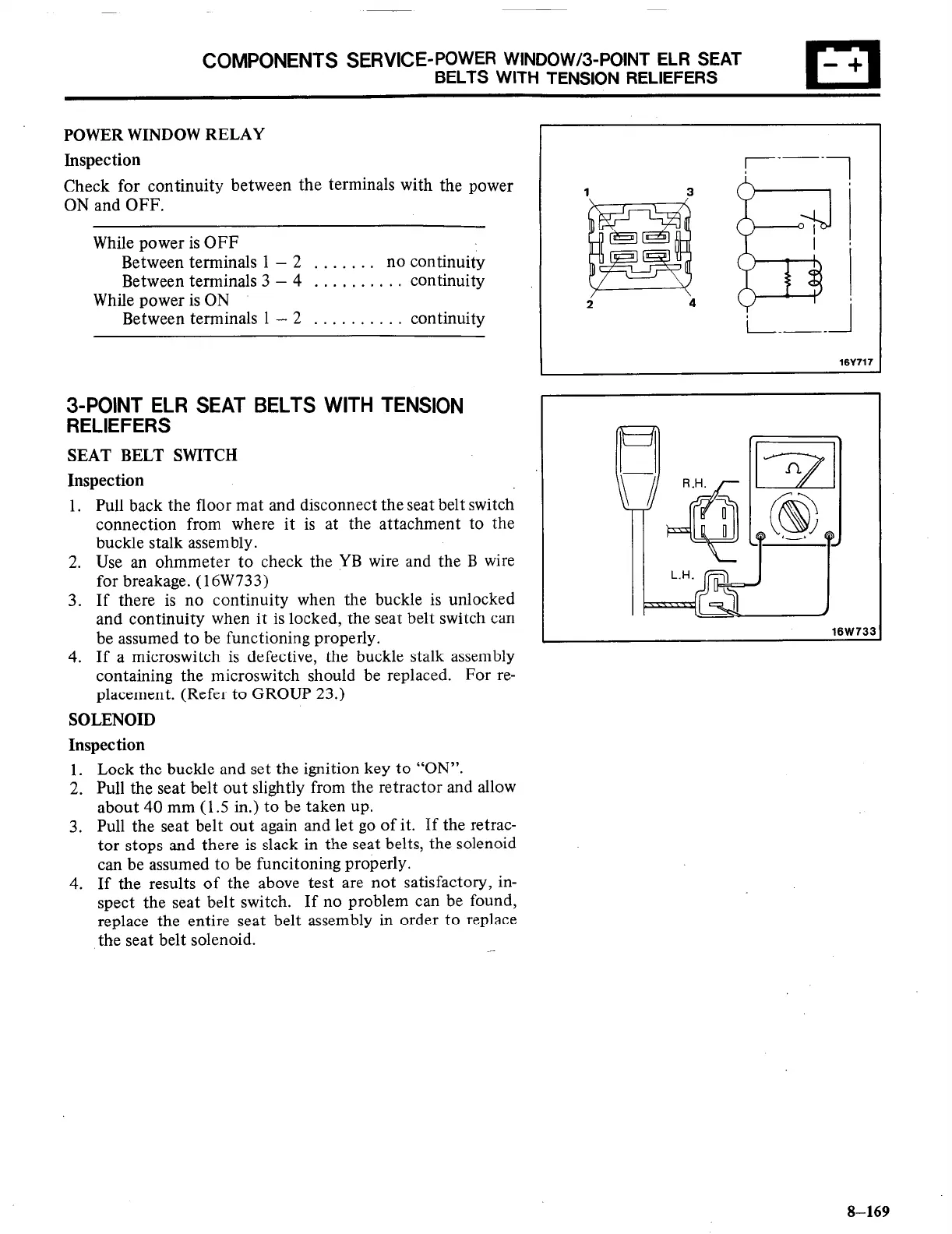

SEAT BELT SWITCH

Inspection

1. Pull back the floor mat and disconnect the seat belt switch

connection from where it is at the attachment to the

buckle stalk assembly.

2. Use an ohmmeter to check the YB wire and the B wire

for breakage. (16W733)

3. If there is no continuity when the buckle is unlocked

and continuity when it is locked, the seat belt switch can

be assumed to be functioning properly.

4. If a microswitch is defective, the buckle stalk assembly

containing the microswitch should be replaced. For re-

placement. (Refer to GROUP 23.)

SOLENOID

Inspection

1. Lock the buckle and set the ignition key to “ON”.

2. Pull the seat belt out slightly from the retractor and allow

about 40 mm (1.5 in.) to be taken up.

3. Pull the seat belt out again and let go of it. If the retrac-

tor stops and there is slack in the seat belts, the solenoid

can be assumed to be funcitoning properly.

4. If the results of the above test are not satisfactory, in-

spect the seat belt switch.

If no problem can be found,

replace the entire seat belt assembly in order to replace

the seat belt solenoid.

16Y717

8-169

Loading...

Loading...