COMPONENT SERVICE-STARTING SYSTEM

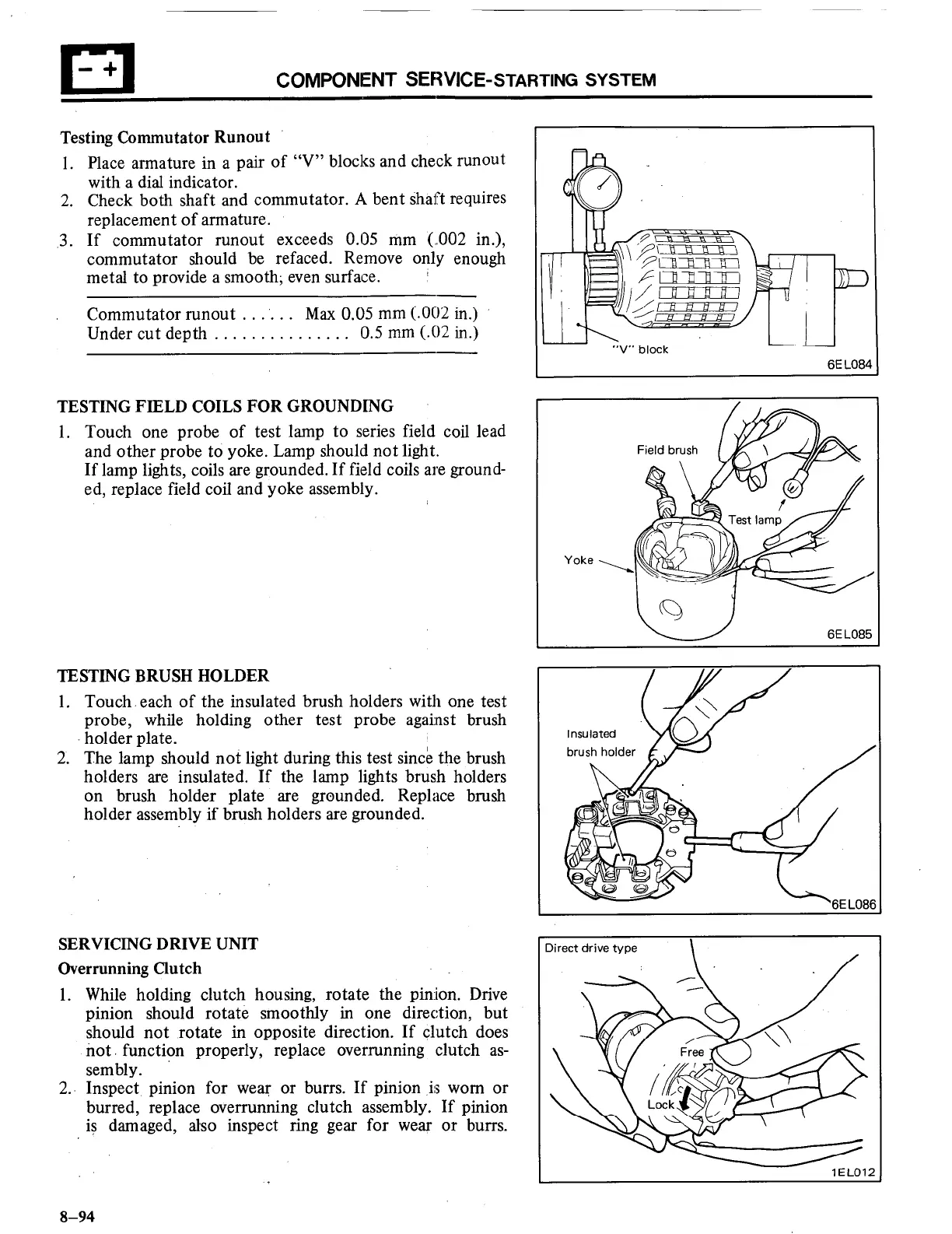

Testing Commutator Runout

1. Place armature in a pair of “V” blocks and check runout

with a dial indicator.

2. Check both shaft and commutator. A bent shaft requires

replacement of armature.

,3. If commutator runout exceeds 0.05 mm (002 in.),

commutator should be refaced. Remove only enough

metal to provide a smooth; even surface.

/

Commutator runout . . . ‘. . . Max 0.05 mm (.002 in.)

Under cut depth . . . . . . . . . . . . . . . 0.5 mm (.02 in.)

TESTING FIELD COILS FOR GROUNDING

1. Touch one probe of test lamp to series field coil lead

and other probe to yoke. Lamp should not light.

If lamp lights, coils are grounded. If field coils are ground-

ed, replace field coil and yoke assembly.

TESTING BRUSH HOLDER

1. Touch. each of the insulated brush holders with one test

probe, while holding other test probe against brush

holder plate.

2. The lamp should not light during this test since the brush

holders are insulated. If the lamp lights brush holders

on brush holder plate are grounded. Replace brush

holder assembly if brush holders are grounded.

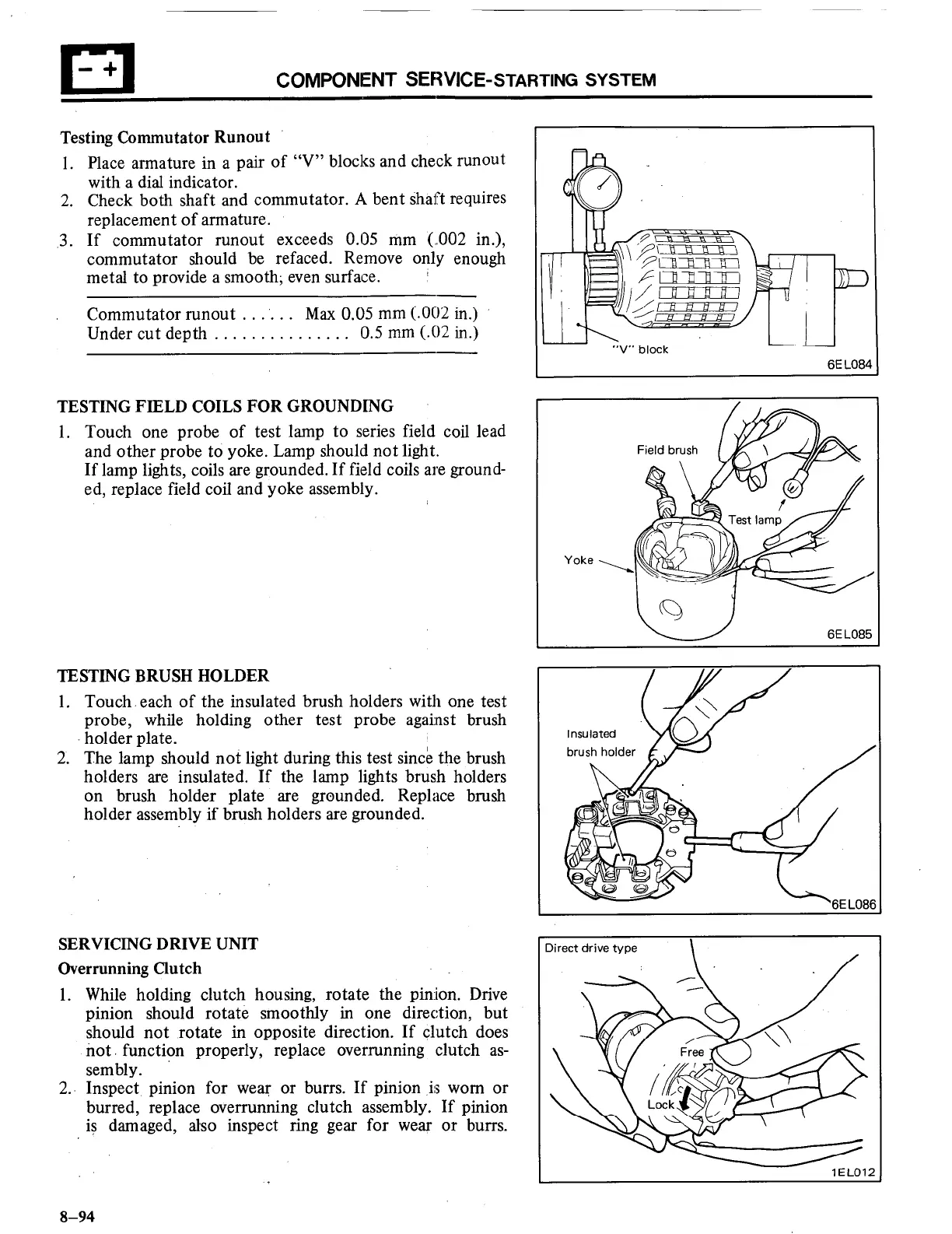

SERVICING DRIVE UNIT

Overrunning Clutch

1. While holding clutch housing, rotate the pin:ion. Drive

pinion should rotate smoothly in one direction, but

should not rotate in opposite direction. If clutch does

not. function properly, replace overrunning clutch as-

sembly.

2.’ Inspect pinion for wear or burrs. If pinion ,i:s worn or

burred, replace overrunning clutch assembly. If pinion

is damaged, also inspect ring gear for wear or burrs.

Yoke ,

6E LO85

Direct drive type

\ /

lEL012

8-94

Loading...

Loading...