SERVICE ADJUSTMENT PROCEDURES

SPARK PLUG INSPECTION AND TEST

1.

2.

3.

4.

5.

Remove the spark plugs from the engine.

Visually check the spark plugs for the following and

replace if defective.

l

Broken insulator.

l

Worn electrode.

l

Deposited carbon. Use a plug cleaner for cleaning.

Clean porcelain insulator above shell as well.

l

Damaged or broken gasket.

l

Burnt condition of porcelain insulator at spark gap.

If black carbon deposit is evident, probable cause is

too rich a fuel mixture or extremely low air intake.

Misfiring due to excessive spark gap is also suspected.

If insulator is burnt white, too lean a fuel mixture,

excessively advanced ignition timing, improperly

tightened plug, etc. are suspected.

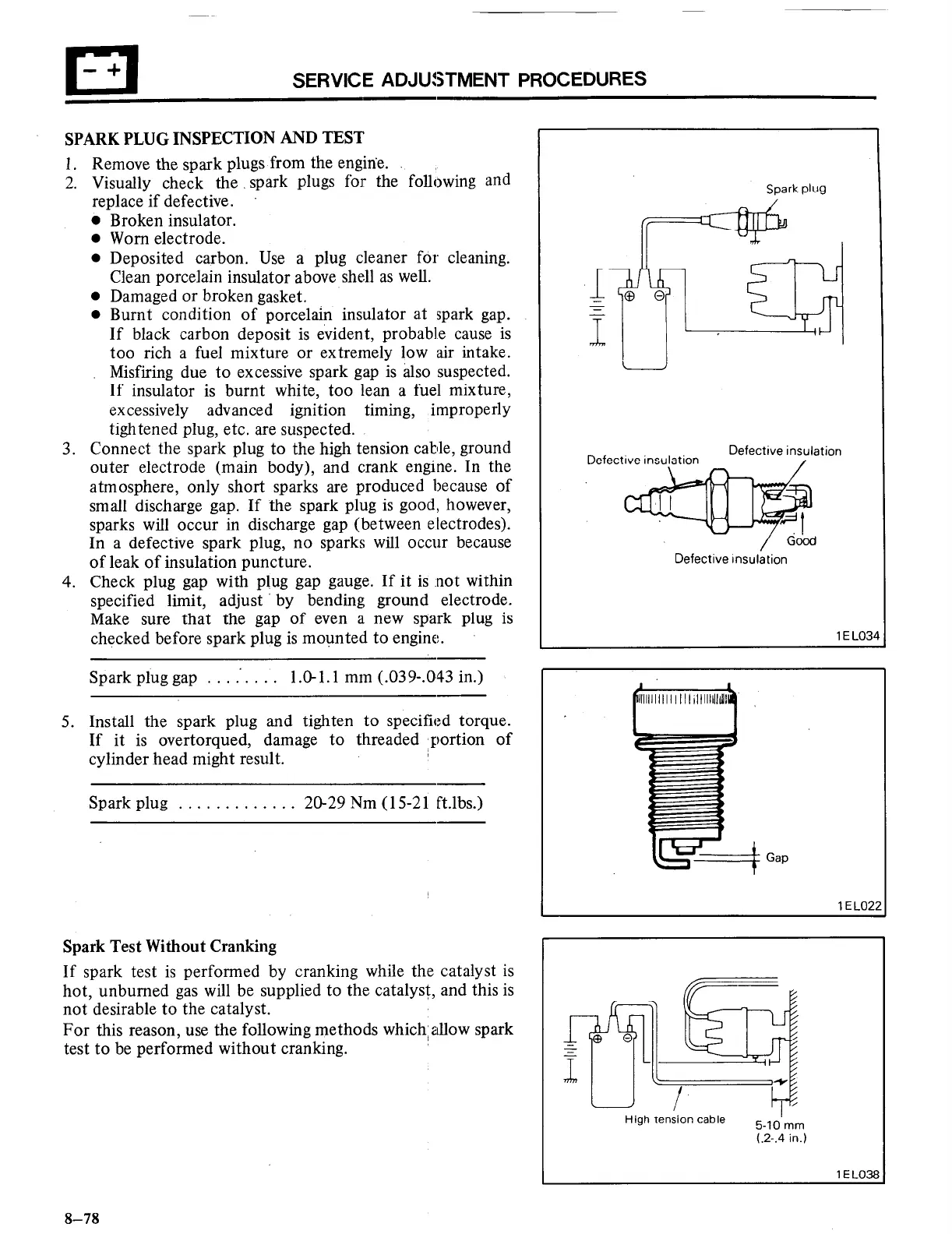

Connect the spark plug to the high tension cable, ground

outer electrode (main body), and crank engine. In the

atmosphere, only short sparks are produced because of

small discharge gap. If the spark plug is good, however,

sparks will occur in discharge gap (between electrodes).

In a defective spark plug, no sparks will occur because

of leak of insulation puncture.

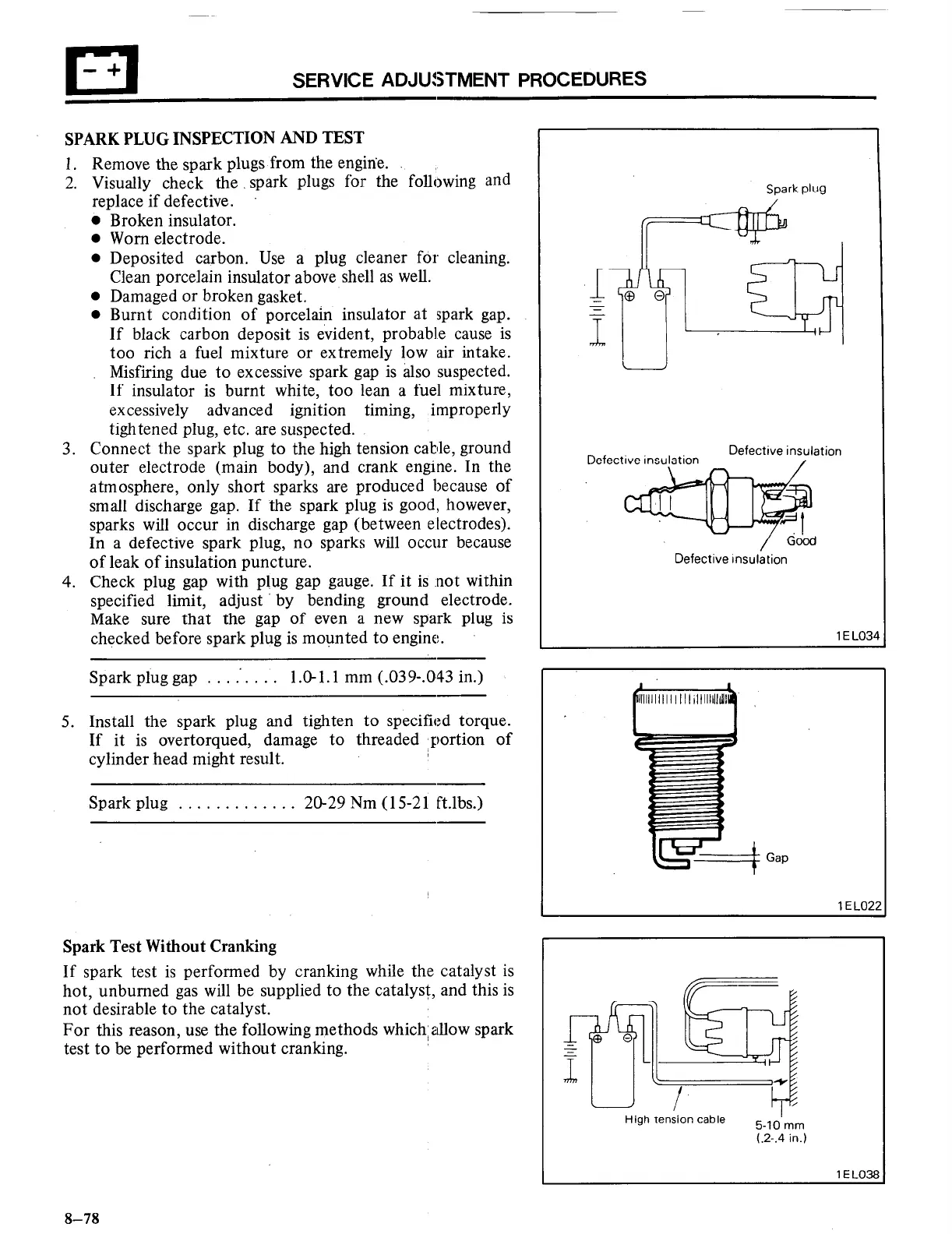

Check plug gap with plug gap gauge. If it is .not within

specified limit, adjust by bending ground electrode.

Make sure that the gap of even a new spark plug is

checked before spark plug is mounted to engine.

Spark plug gap . . . .’ . . . .

1.0-1.1 mm (.039-.0’43 in.)

Install the spark plug and tighten to specified torque.

If it is overtorqued, damage to threaded ,portion of

cylinder head might result.

/

Spark plug . . . . . . . . . . . . . 20-29 Nm (15-21 ft.lbs.)

Spark Test Without Cranking

If spark test is performed by cranking while the catalyst is

hot, unburned gas will be supplied to the catalyst, and this is

not desirable to the catalyst.

For this reason, use the following methods which;allow spark

test to be performed without cranking.

Spark plug

Defective insulation

Defective insuktion

1 E LO3,

I”-\.

lllllllllllllllillllllllllll

Gap

lELO2

High tension cable

5-10 mm

(.2-.4 in.)

lEL03

8-78

Loading...

Loading...