COMPONENT SERVICE-CHARGING

SYSTEM

stator

1. Make continuity test on stator coil. Check to ensure that

there is continuity between coil leads.

If there is no continuity, replace stator assembly.

21 Check coil for grounding. Check to ensure that there is

no continuity between coil and core. If there is con-

tinuity, replace stator assembly.

Ret tifier

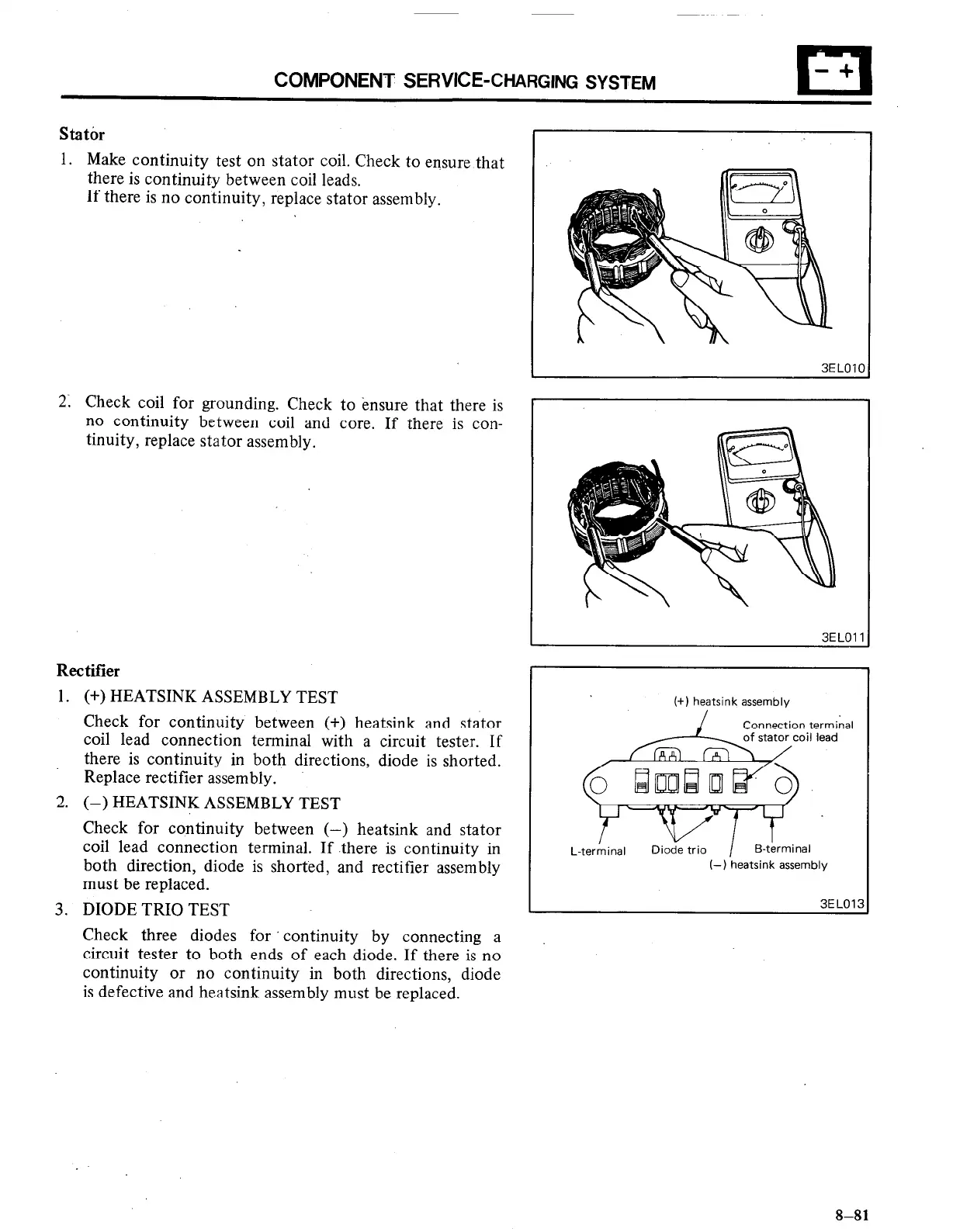

1. (+) HEATSINK ASSEMBLY TEST

Check for continuity between (+) heatsink and stator

coil lead connection terminal with a circuit tester. If

there is continuity in both directions, diode is shorted.

Replace rectifier assembly.

2. (-) HEATSINK ASSEMBLY TEST

Check for continuity between (-) heatsink and stator

coil lead connection terminal. If .there is continuity in

both direction, diode is shorted, and rectifier assembly

must be replaced.

3. DIODE TRIO TEST

Check three diodes for continuity by connecting a

circuit tester to both ends of each diode. If there is no

continuity or no continuity in both directions, diode

is defective and heatsink assembly must be replaced.

I

3ELOlC

I

3ELOll

(+) heatsink assembly

Connection terminal

nf stator coil lead

I

L-terminal

Die% trio

/ B-tkrminal

I-) heatsink assembly

3ELOl:

8-81

Loading...

Loading...