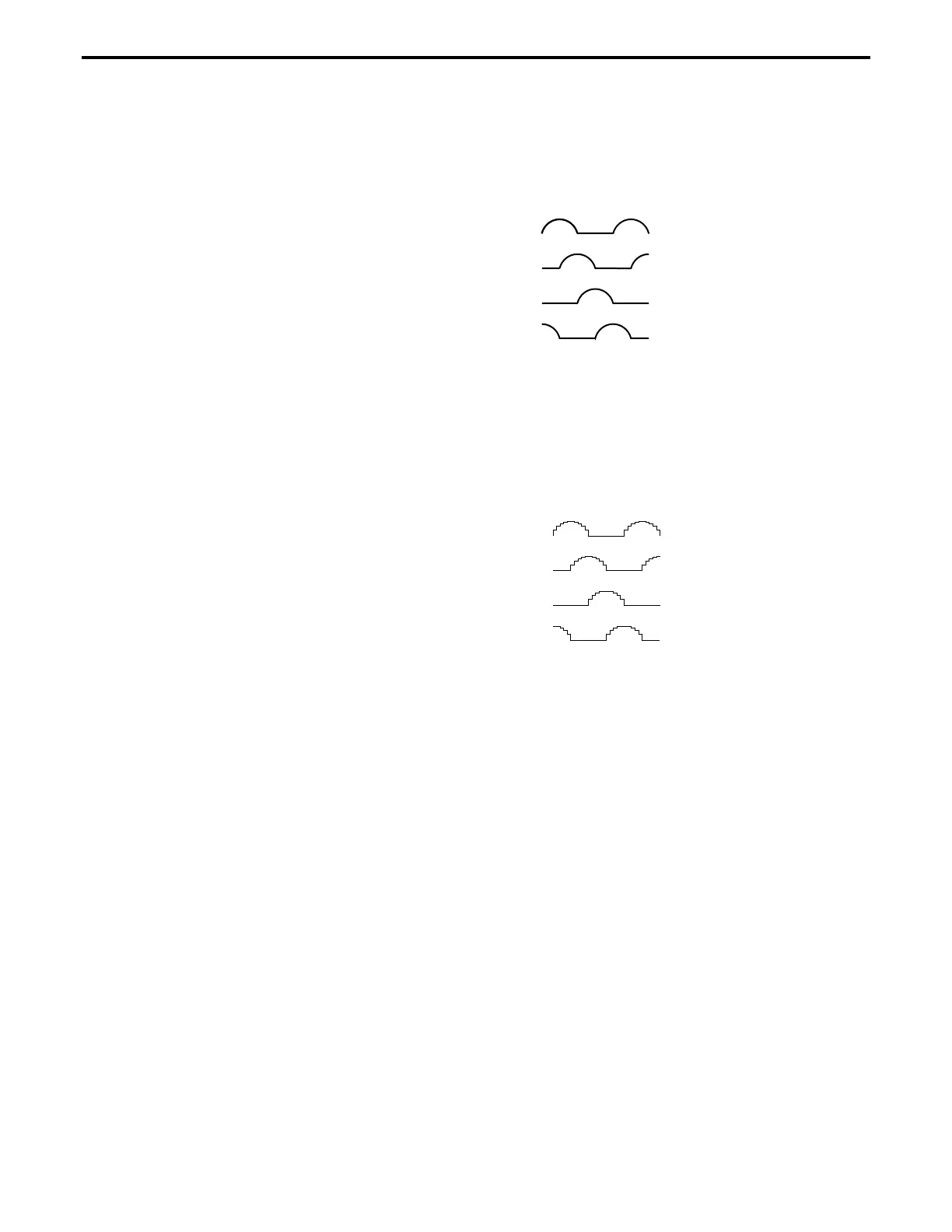

The conclusion is that, varying the ratio between the currents of the

two phases, the user can position the rotor anywhere between the two

full step locations. To do so, the user needs to drive the motor with

analog signals, similar to (

Figure 5.37).

A

B

C

D

Figure 5.37: Timing Diagram, Continuous Motion (Ideal)

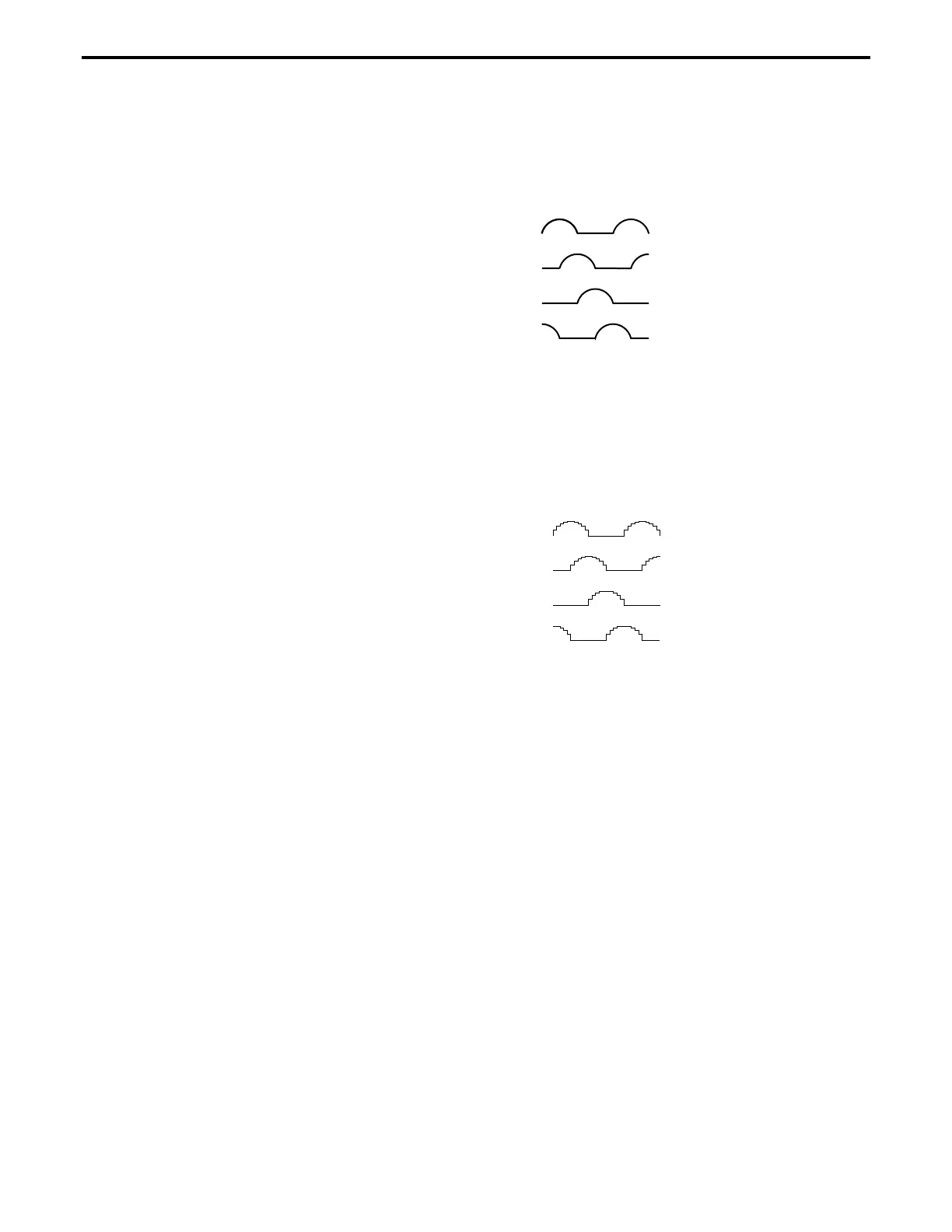

But a stepper motor should be stepping. The controller needs to move

it in certain known increments. The solution is to take the halh-sine

waves and digitize them so that for every step command, the currents

change to some new pre-defined levels, causing the motor to advance

one small step (

Figure 5.38).

A

B

C

D

Figure 5.38: Timing Diagram, Mini-Stepping

This driving method is called mini-stepping or micro-stepping. For

each step command, the motor will move only a fraction of the full-

step. Motion steps are smaller so the motion resolution is increased

and the motion ripple (noise) is decreased.

However, mini-stepping comes at a price. First, the driver electronics

are significantly more complicated. Secondly, the holding torque or

one step is reduced by the mini-stepping factor. In other words, for a

x10 mini-stepping, it takes only 1/10 of the full-step holding torque to

cause the motor to have a positioning error equivalent to one step (a

mini-step).

To clarify a little what this means, lets take a look at the torque

produced by a stepper motor. For simplicity, lets consider the case of

a single phase being energized (

Figure 5.39).

Once the closest rotor tooth has been pulled in, assuming that the user

doesn't have any external load, the motor does not develop any

torque. This is a stable point.

Section 5 – Motion Control Tutorial 5-29

Loading...

Loading...