There are two basic types of encoders: linear and rotary. The linear

encoders, also called linear scales, are used to measure linear motion

directly. This means that the physical resolution of the scale will be

the actual positioning resolution. This is their main drawback since

technological limitations prevent them from having better resolutions

than a few microns. To get higher resolutions in linear scales, a

special delicate circuitry must be added, called scale interpolator.

Other technologies like interferometry or halography can be used but

they are significantly more expansive and need more space.

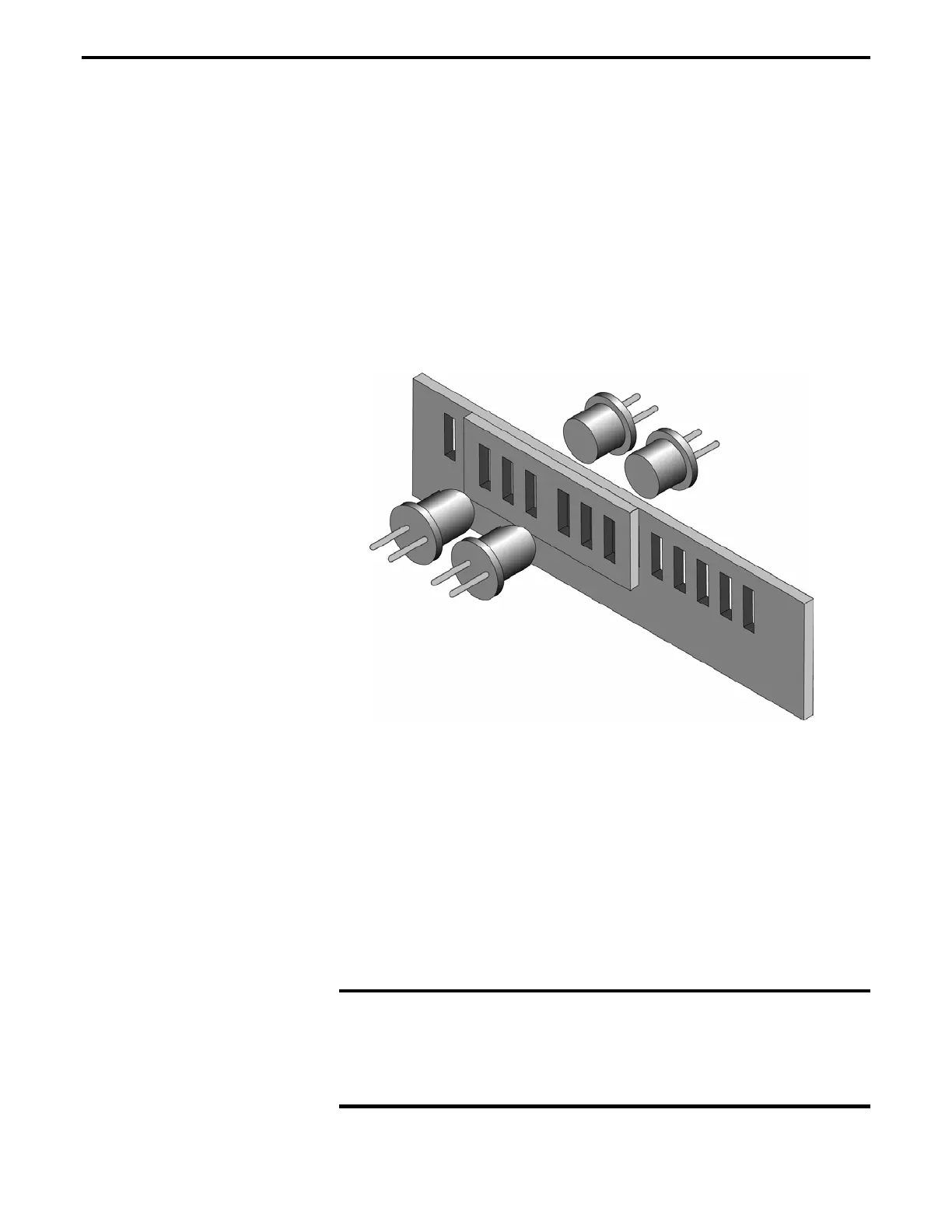

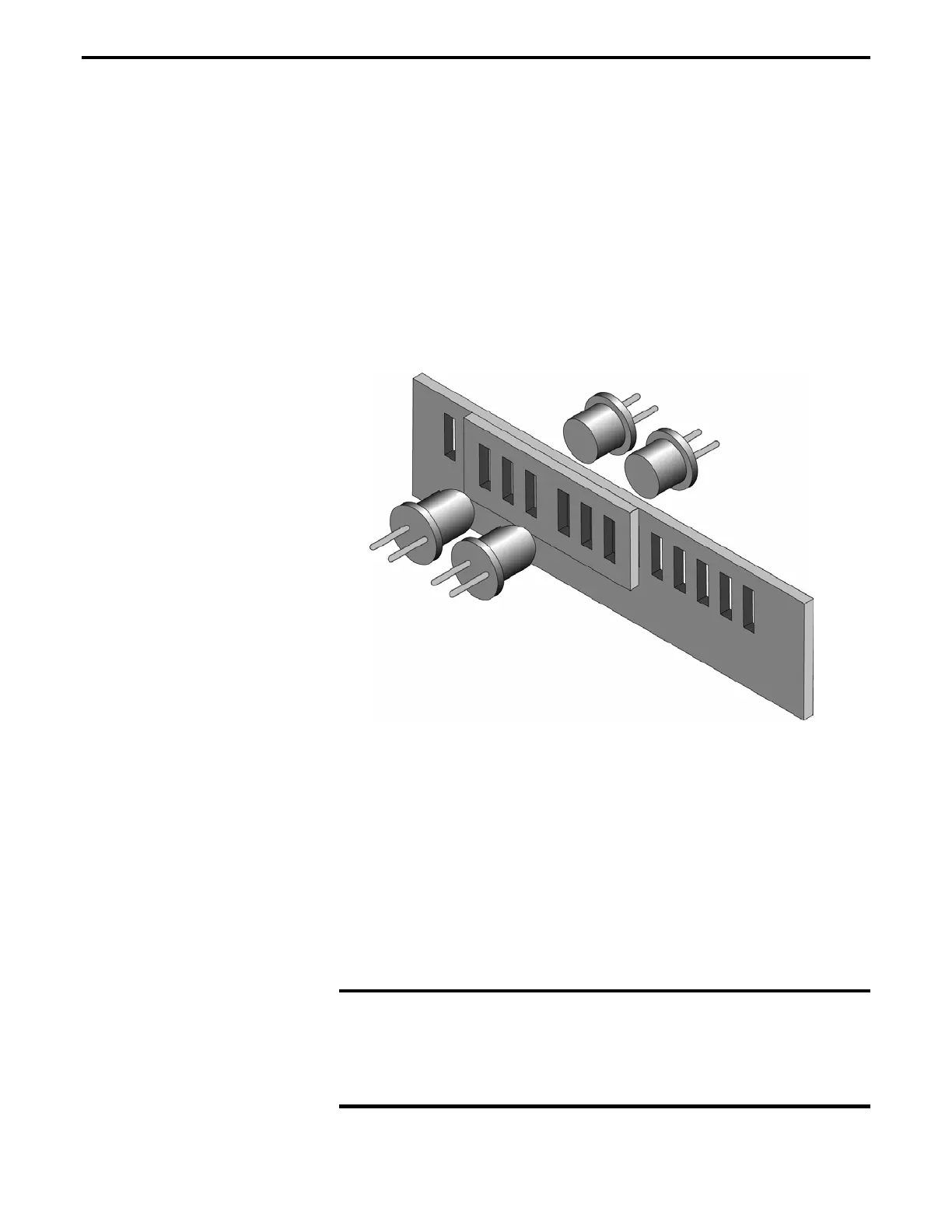

Figure 5.30: Two-Channel Optical Encoder Scale and Read Head Assembly

The most popular encoders are rotary. Using gear reduction between

the encoder and the load, significant resolution increases can be

obtained at low cost. But the price paid for this added resolution is

higher backlash.

In some cases, rotary encoders offer high resolution without the

backlash penalty. For instance, a linear translation stage with a rotary

encoder on the lead screw can easily achieve 1 µm resolution with

negligible backlash.

NOTE

For rotary stages, a rotary encoder measures the output angle

directly. In this case, the encoder placed on the rotating platform

has the same advantages and disadvantages of the linear scales.

Section 5 – Motion Control Tutorial 5-25

Loading...

Loading...