Parker EME

Setting up Compax3

192-120113 N08 C3I12T11 - December 2010

Feedforward channels

In this chapter you can read about:

Influence of the feedforward measures .......................................................................... 209

Motion cycle without feedforward control ....................................................................... 210

Motion cycle with feedforward measures ....................................................................... 210

The feedforward channels are used for the specific influence of the guiding

behavior of a control. The calculated and evaluated status variables are coupled

into the corresponding places within the controller cascade. In practice, the

feedforward control offers the following advantages:

Minimal following error

Improves the transient response

Gives greater dynamic range with lower maximum current

The Compax3 servo drive disposes of four feedforward measures (see in the

standard cascade structure):

Velocity Feed Forward

Acceleration feed-forward

Current feed-forward

Jerk feed-forward

The above order represents at the same time the effectiveness of the individual

feedforward measures. The influence of the jerk feedforward may be, depending

on the profile and the motor, negligibly small.

But the principle of feedforward control fails in limiting the motor current or the

motor speed during the acceleration phase!

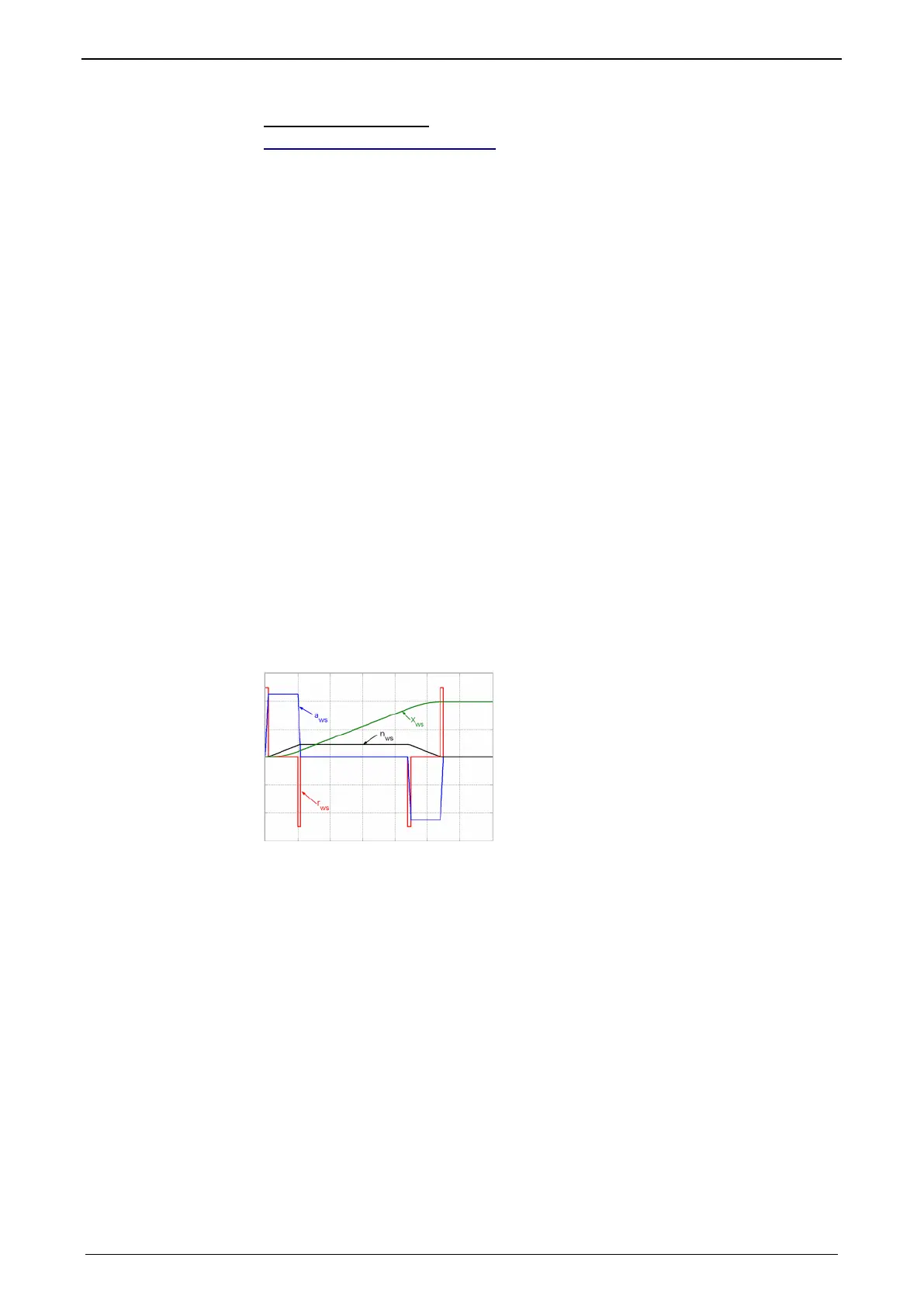

Influence of the feedforward measures

Following error minimization by feedforward control / course of the setpoint

generator signals

xws: Position setpoint value of the setpoint generator

nws: Velocity setpoint - setpoint generator

aws: Acceleration setpoint value setpoint generator

rws: Jerk setpoint value setpoint generator

Loading...

Loading...