14

120 Workshop Manual, TPD 1377E, issue 4

100 Series

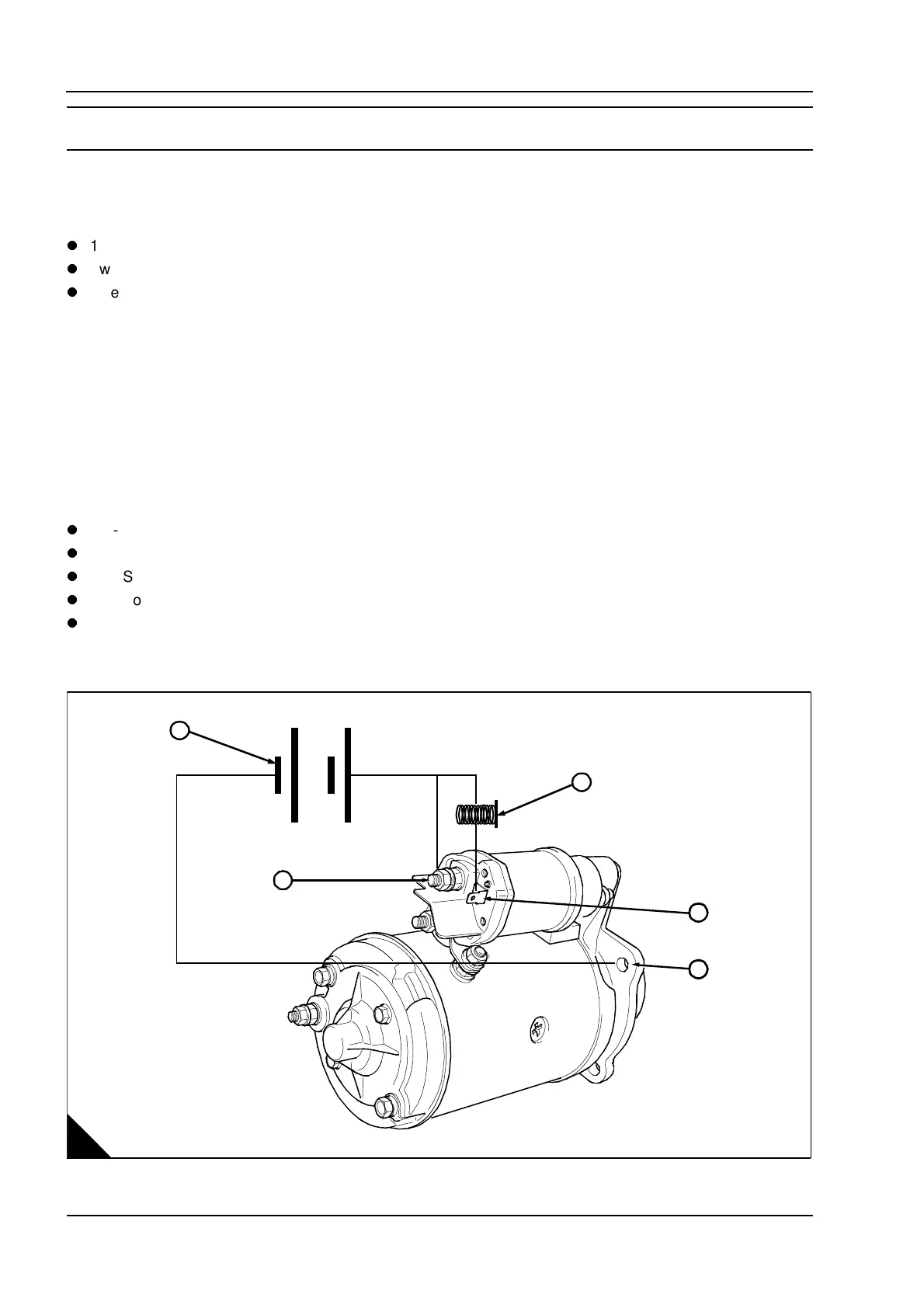

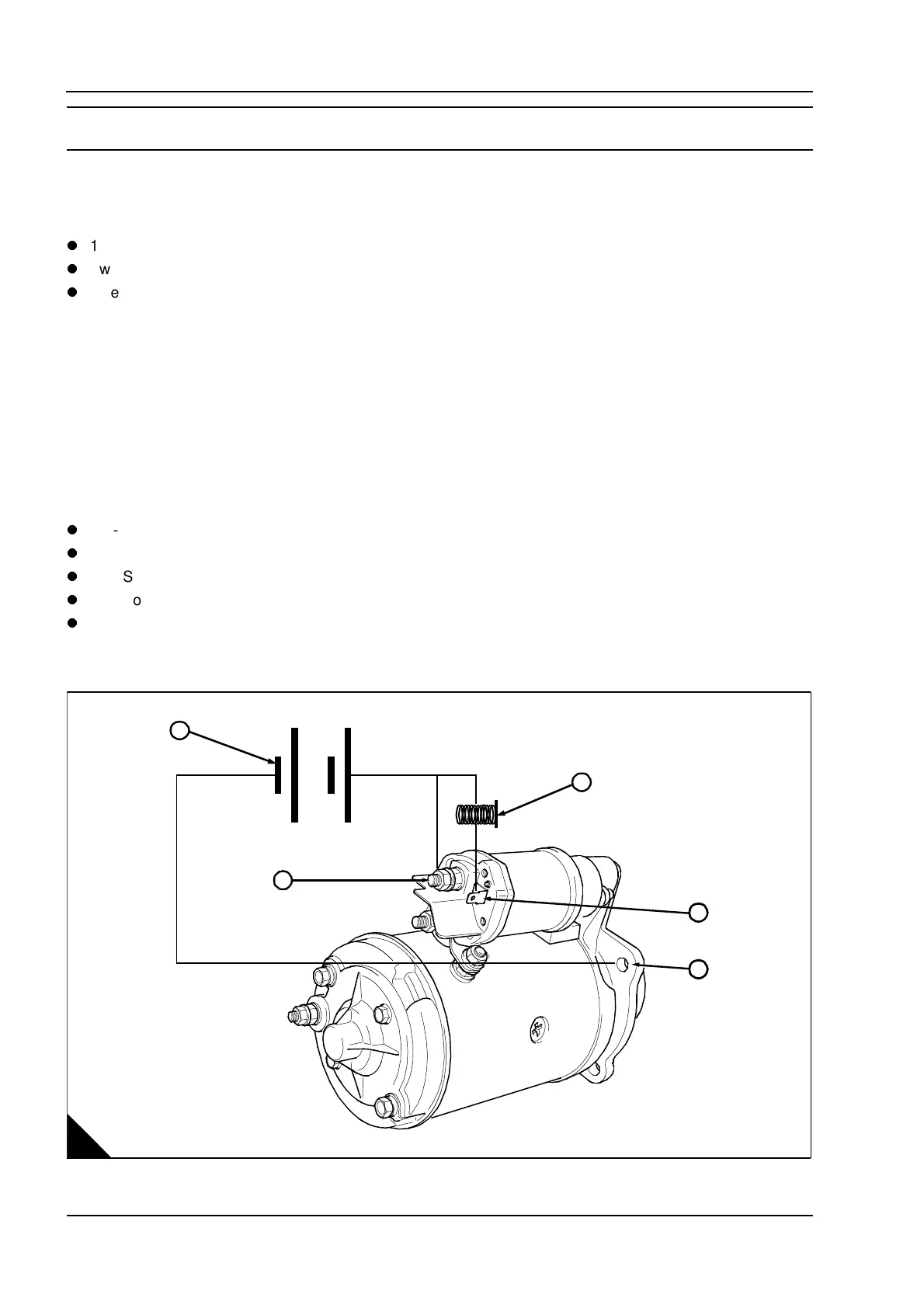

Starter Motor Testing Operation 14-5

Before removing a suspect faulty starter motor, check the security of all of the electrical connections on the

starter motor.

To test the starter motor use:

12 volt fully charged battery (A5).

Two heavy duty cables with suitable clips.

One small lead with an in-line switch capacity of 5 amperes minimum. The switch (A1) should be of the

push to make type.

Secure the starter motor in a vice.

Connect the leads as shown in the diagram (A2, A3, A4), there should be no operation of the starter motor. If

there is any smoke, buzzing or sparking from the starter motor, it is faulty.

Operate the switch and the solenoid should operate, moving the pinion forward to engage the starter. The

starter motor pinion will then rotate. Releasing the switch will allow the pinion to retract and stop rotating.

If there is any abnormal noise, such as knocking, electrical buzzing, smoke, the starter does not operate, or

the pinion does not move forward or backward, or the pinion does not rotate, the starter motor is faulty.

If the starter motor operates correctly then the machine electrical system is faulty.

A1 - Lead with push button switch.

A2 - Lucar connector for ignition switch.

A3 - Starter earth connection 8.0 - 8.5 Nm

A4 - Solenoid connection 5.6 - 6.2 Nm.

A5 - 12 volt battery.

Note: The starter motor earth (A3) should be connected directly to B- or via another earth. This should not be

used as the main engine earth.

A

K1244

2

4

3

1

5

-

+

This document has been printed from SPI². Not for Resale

Loading...

Loading...