2

14 Workshop Manual, TPD 1377E, issue 4

100 Series

Thread Sealant

When setscrews or studs are fitted into holes which are tapped through the cylinder block, a suitable sealant

must be used to prevent leakage.

Micro encapsulated anaerobic sealant (M.E.A.S) fasteners have been introduced instead of jointing

compounds or other sealants when the fasteners are fitted in through holes into oil or coolant passages. The

identification of these fasteners, as supplied, is by a red, blue, or other colour sealant around the fastener

threads.

With M.E.A.S. sealed studs, the sealed end must be fitted into the cylinder head / cylinder block etc. Ensure

that the threaded holes have a 1,59 mm (0.0625 in) 45° chamfer, to ensure that when the new fasteners are

fitted the M.E.A.S. sealant is not removed. If the fasteners have to be removed and fitted again, the threads

must be cleaned and a suitable sealant used.

Note: New setscrews have sealant applied by the manufacturer to the first 13,0 mm (0.50 in) of the threads.

If the setscrews are to be used again, clean the old sealant from the male and female threads and apply new

sealant, (Powerpart Threadlock and Nutlock) to the setscrews.

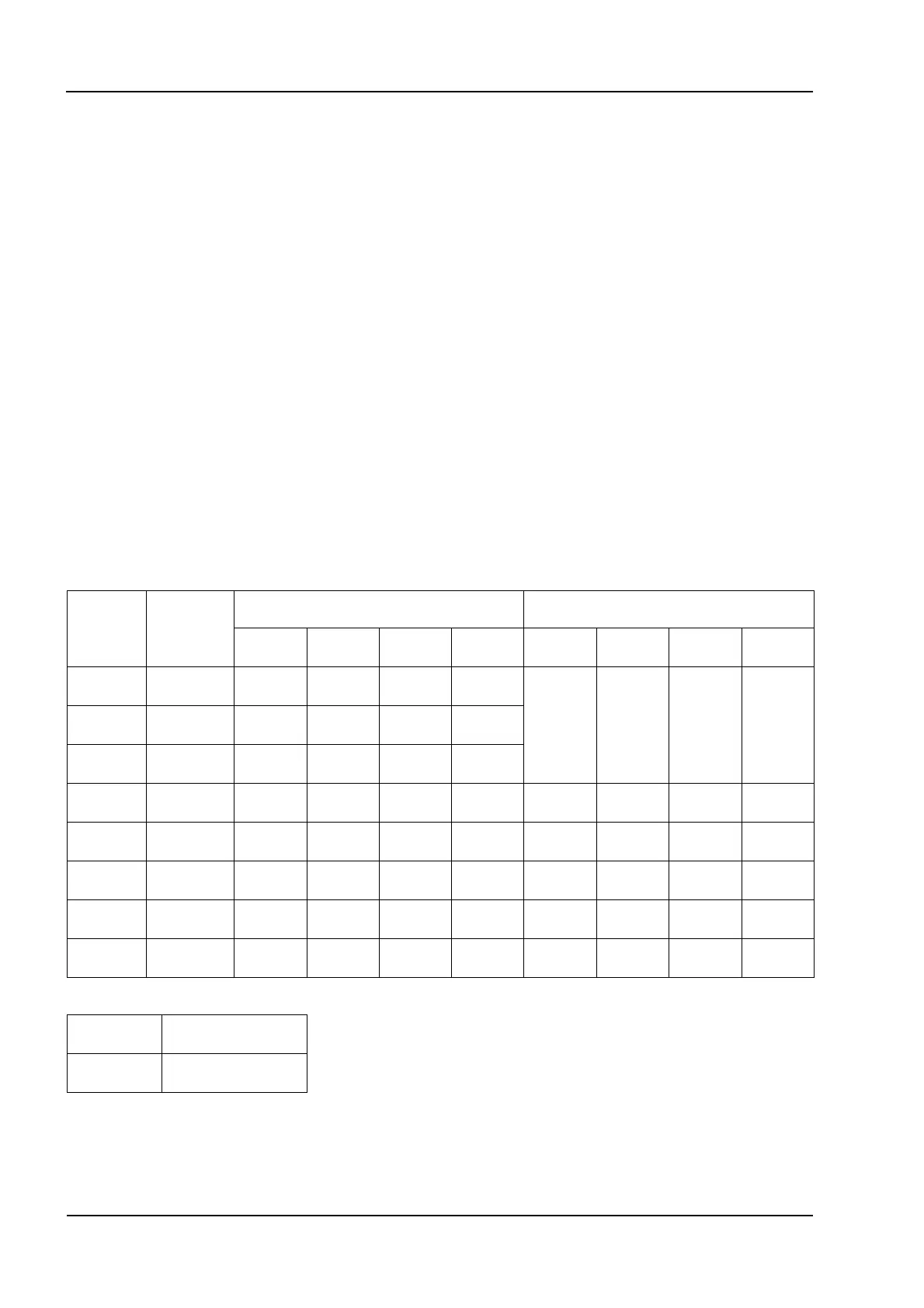

Recommended torque tensions

Most of the torques on the engine are standard. Torques specific to individual operations are listed in the

relevant operation. The standard torques listed in the tables below can be used when a specific torque is not

necessary.

Note: The torques below apply to components lubricated lightly with clean engine oil before they are fitted.

Standard torques for setscrews, studs and nuts

Examples of applicable material

Thread

size

Bolt

Strength

Coarse Screw Thread Fine Screw Thread

Pitch

(mm)

Torque

(Nm)

Torque

(lbf ft)

Torque

(kgf m)

Pitch

(mm)

Torque

(Nm)

Torque

(lbf ft)

Torque

(kgf m)

M4

8.8

11T

0,7

3

4

2

3

0,3

0,4

M5

8.8

11T

0,8

6

8

4

6

0,6

0,8

M6

8.8

11T

1,0

10

14

7

10

1,0

1,4

M8

8.8

11T

1,25

26

32

19

24

2,7

3,3

1,0

30

35

22

26

3,0

3,6

M10

8.8

11T

1,5

50

62

37

46

5,1

6,3

1,25

56

66

41

49

5,7

6,7

M12

8.8

11T

1,75

75

104

55

77

7,6

10,6

1,25

84

113

62

83

8,6

11,5

M14

8.8

11T

2,0

118

157

87

116

12,0

16,0

1,5

132

167

97

123

13,5

17,0

M16

8.8

11T

2,0

167

230

123

170

17,0

23,4

1,5

175

245

129

181

17,8

20,5

Bolt

Strength

Example

8.8

11T

S45C

SCM435

This document has been printed from SPI². Not for Resale

Loading...

Loading...