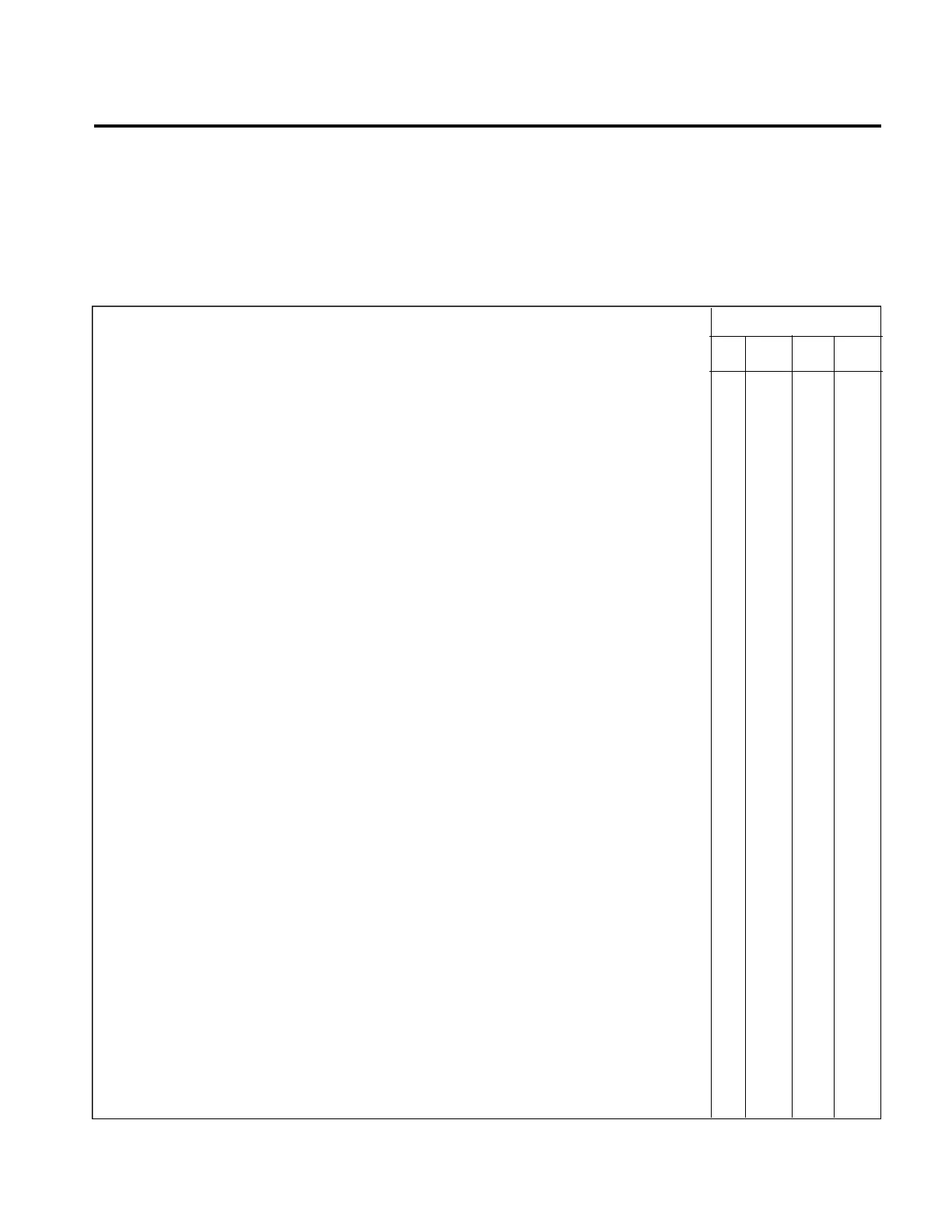

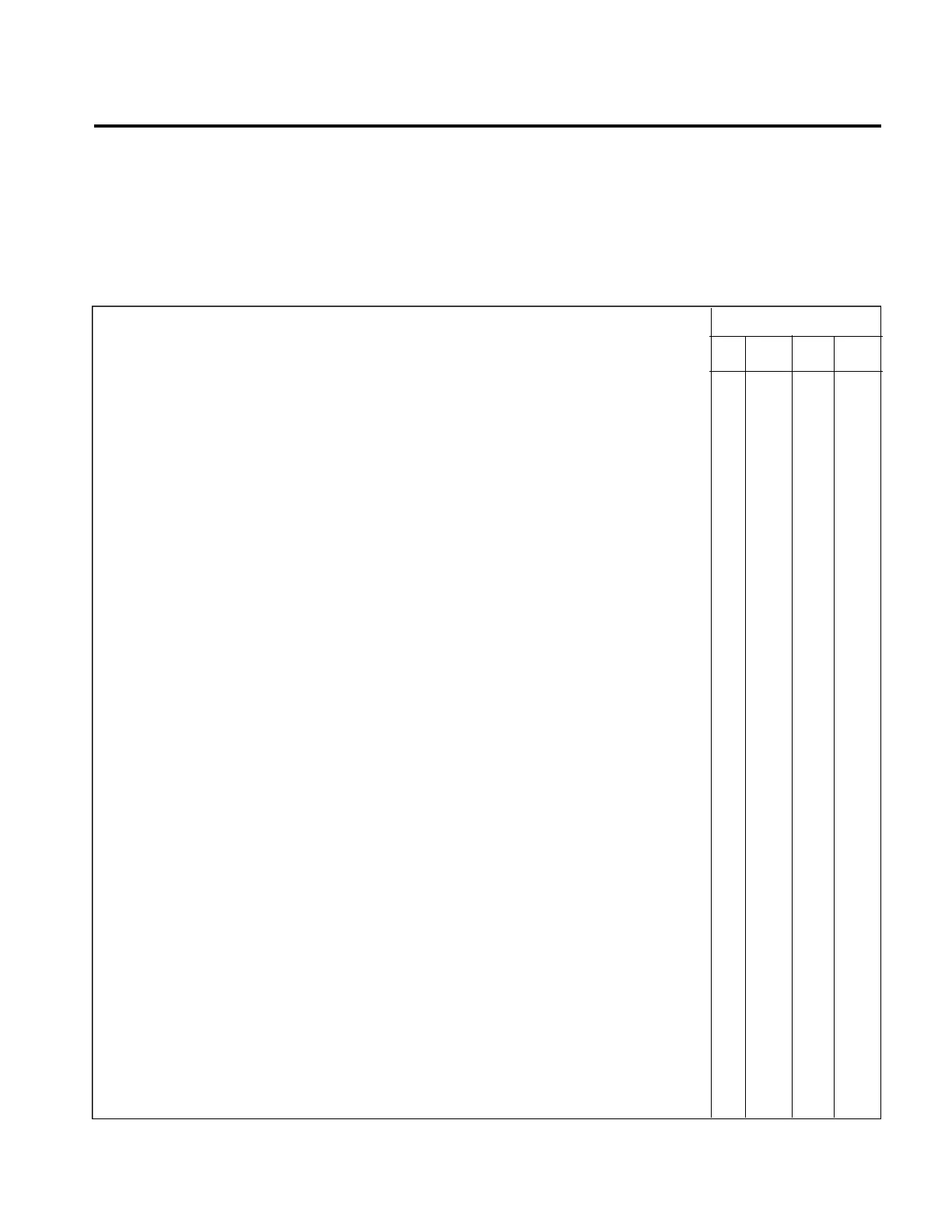

PERIODIC INSPECTIONS (cont)

—NOTE—

Perform all inspections or operations at each inspection interval as

indicated by a circle (O).

Nature of Inspection

B. ENGINE GROUP (cont)

7. Inspect oil lines and fitting for leaks, security, chafing, dents, and cracks.

(See Note 7.)............................................................................................................ O O O O

8. Clean and inspect oil radiator cooling fins.............................................................. O O O

9. Remove and flush oil radiator ................................................................................. O O

10. Fill engine with oil per lubrication chart. (Refer to chapter l2.).............................. O O O O

CAUTION: Do not contaminate the vacuum pump with cleaning

fluid. (Ref: Latest revision of Lycoming Service

Instruction No. l22l.)

11. Clean engine ............................................................................................................ O O O

12. Inspect condition of spark plugs. (Clean and adjust gap as required, adjust

per latest revision of Lycoming Service Instruction No. 1042.)..............................

(See Note 14.) ......................................................................................................... O O O

NOTE: If fouling of spark plugs has been apparent, rotate

bottom plugs and upper plugs.

13. Inspect spark plug cable leads and ceramics for corrosion and deposits................. O O O

14. Check cylinder compression. (Ref: Latest revision of AC 43.l3-l.)........................ O O O

15. Inspect cylinders for cracked or broken fins............................................................ O O O

16 Inspect rocker box covers for evidence of oil leaks. If found, replace

gasket; tighten cover screws to a torque of 50 inch-pounds. (See Note 12.)........... O O O O

NOTE: Lycoming requires a valve inspection be made after

every 400 hours of operation. (See Note l l.)

17. Inspect ignition harness and insulators for high tension leakage and continuity .... O O O

18. Inspect magneto points for condition and proper clearance.................................... O O O

19. Inspect magneto for oil leakage .............................................................................. O O O

20. Inspect breaker felts for proper lubrication ............................................................. O O O

21. Inspect distributor block for cracks, burned areas, corrosion, and

height of contact springs ......................................................................................... O O

22. Check magnetos to engine timing ........................................................................... O O O

23. Overhaul or replace magnetos. (See Note 6.)

24. Remove air filter and tap gently to remove dirt particles. (Replace as

required.).................................................................................................................. O O O O

25. Drain carburetor and clean inlet line fuel strainer................................................... O O O O

26. Inspect condition of carburetor heat air-door and box. (See Note l3.) ................... O O O O

27. Inspect vent lines for evidence of fuel or oil seepage.............................................. O O O O

28. Inspect intake seals for leaks and clamps for tightness ........................................... O O O O

29. Inspect all air inlet duct hoses. (Replace as required.) ............................................ O O O O

50

500

1000

100

Inspection Time (HRS)

PIPER AIRCRAFT

PA-28-236

MAINTENANCE MANUAL

5 - 21 - 00

Page -5 - 03

Reissued: August 1, 1986

Loading...

Loading...