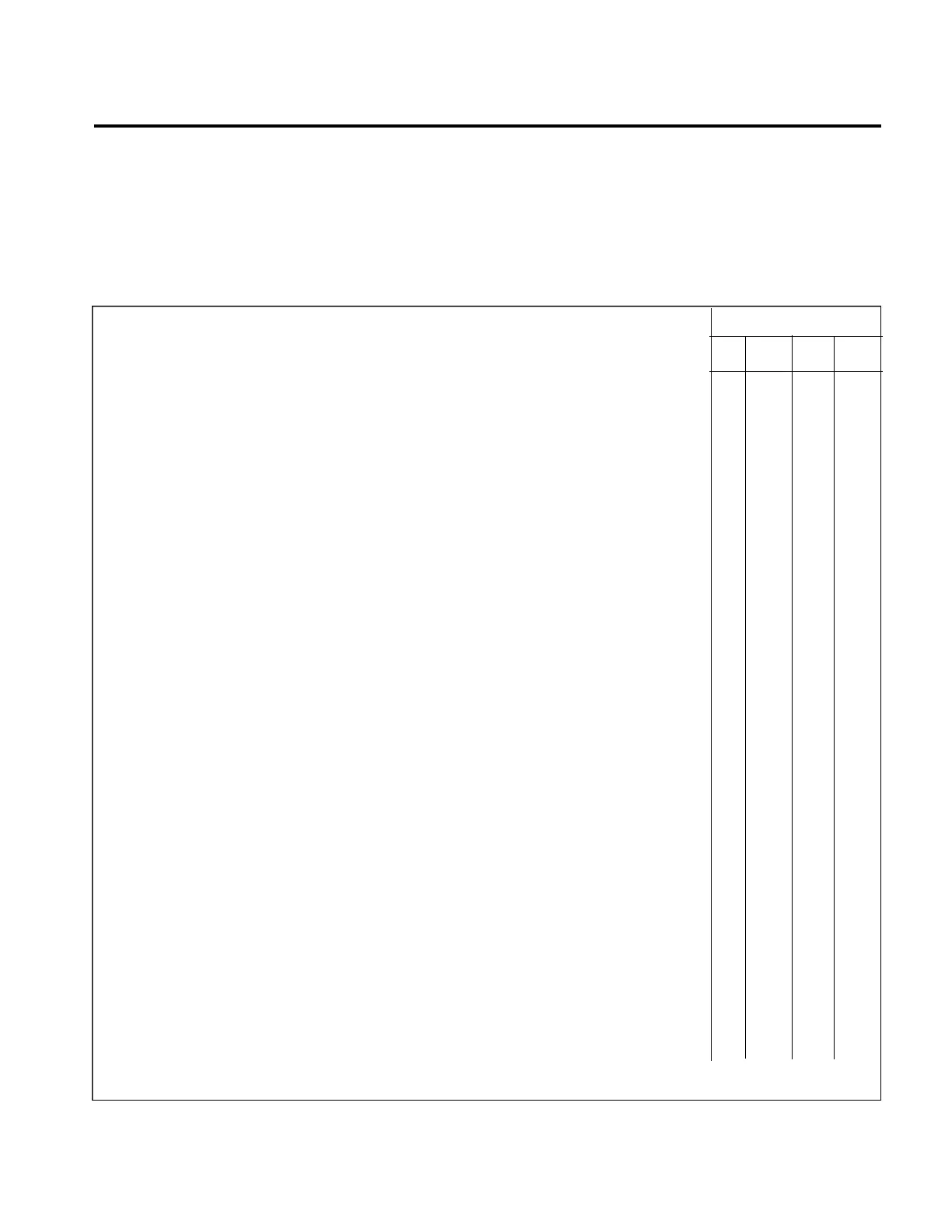

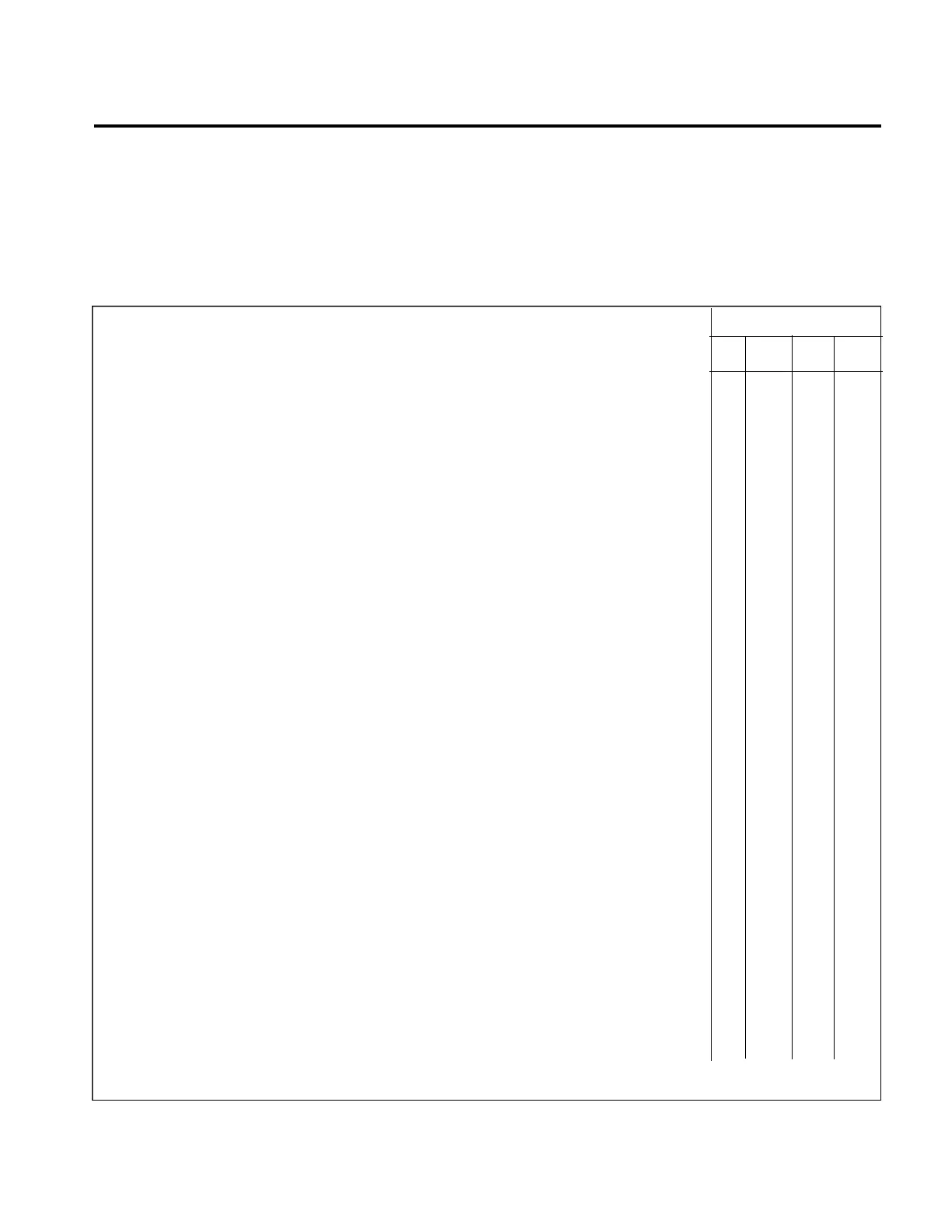

PERIODIC INSPECTIONS (cont)

—NOTE—

Perform oll inspections or operations at each inspection interval as

indicated by a circle (O).

Nature of Inspection

B. ENGlNE GROUP (cont)

30. Inspect condition of flexible fuel lines ................................................................... O O O

31. Replace flexible fuel lines. (See Note 6.)................................................................ O

32. Inspect fuel system for leaks.................................................................................... O O O O

33. Clean screens in electric fuel pump(s) and check operation (engine and

electric).................................................................................................................... O O O O

34. Remove and clean fuel filter bowl and screen. (Clean at least every 90

days.)........................................................................................................................ O O O O

35. Inspect vacuum pump and lines............................................................................... O O O

36. Overhaul or replace vacuum pump. (See Note 6.)................................................... O

37. Inspect throttle, carburetor heat, mixture and propeller governor controls

for security, travel, and operating conditions........................................................... O O O

38. Inspect exhaust stacks, connections, and gaskets. (Refer to chapter 78.)

(Replace gaskets as required.) ................................................................................. O O O

39. Inspect muffler, heat exchange and baffles. (Refer to chapter 78.)......................... O O O

40. Check recommended time for replacement of muffler per chapter 78.................... O O O

41. Inspect breather tube for obstructions and security................................................. O O O

42. Inspect crankcase for cracks, leaks, and security of seam bolts.............................. O O O

43. Inspect engine mounts for cracks and loose mountings .......................................... O O O

44. Inspect all engine baffles ......................................................................................... O O O

45. Inspect all wiring connected to engine or accessories............................................. O O O O

46. Inspect rubber engine mount bushings for deterioration. (Replace as

required.).................................................................................................................. O O O

47. Inspect fire wall seals .............................................................................................. O O O

48. Inspect condition and tension of alternator drive belt. (Refer to chapter 2l.).......... O O O

49. Lubricate alternator and compressor idler pulleys (if installed)

per lubrication chart................................................................................................. O

50. Inspect condition of alternator and starter............................................................... O O O

51. Inspect security of alternator mounting .................................................................. O O O

52. Check air conditioning compressor oil level (See Note 8)

53. Inspect condition of compressor belt and tension. (Refer to chapter 2l.)................ O O O

54. Inspect compressor clutch security and wiring. (See Note 9.) ................................ O O O

55. Inspect security of compressor mounting ............................................................... O O O

56. Check fluid in brake reservoir. (Fill as required.).................................................... O O O O

50

500

1000

100

Inspection Time (HRS)

PIPER AIRCRAFT

PA-28-236

MAINTENANCE MANUAL

5 - 21 - 00

Page -5 - 04

Reissued: August 1, 1986

Loading...

Loading...