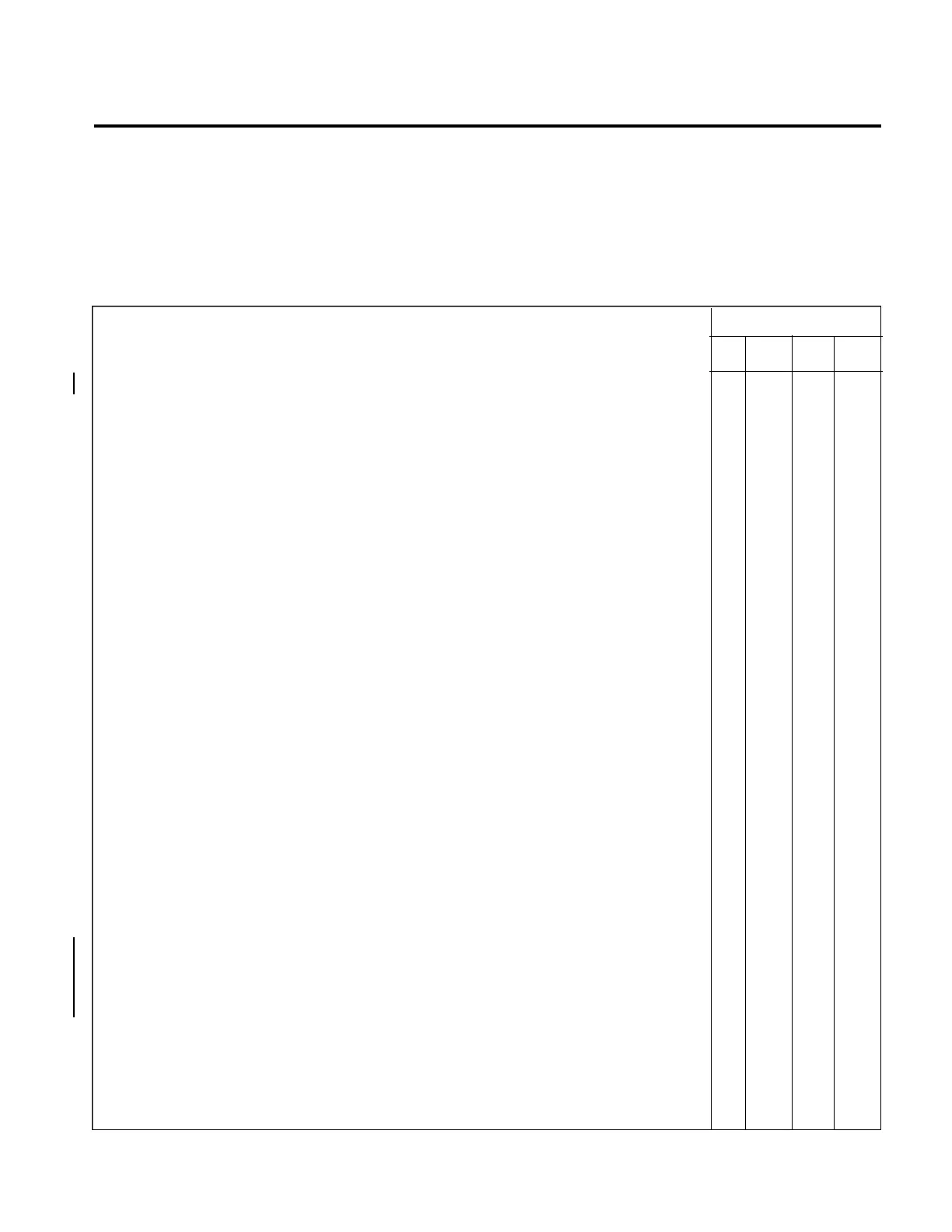

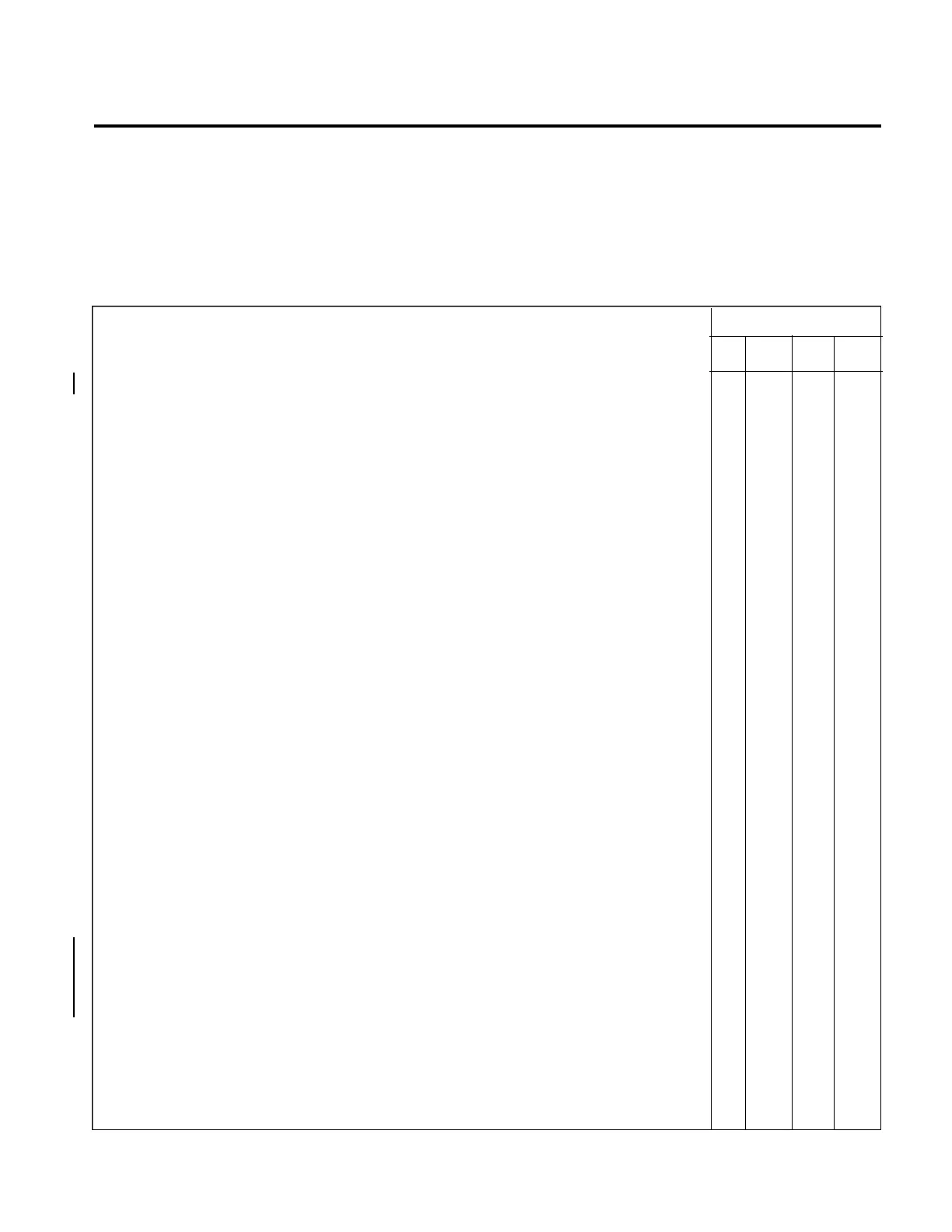

PERIODIC INSPECTIONS (cont)

—NOTE—

Perform all inspections or operations at each inspection interval as

indicated by a circle (O).

Nature of Inspection

D. FUSELAGE AND EMPENNAGE GROUP

l. Remove inspection plates and panels (See Note 21.).............................................. O O O

2. Inspect baggage door, latch, and hinges.................................................................. O O O

3. Inspect battery, box, and cables. Check at least every 30 days. Flush box

as required and fill battery per instructions on box ................................................. O O O O

4. Inspect electronic installation.................................................................................. O O O

5. Inspect bulkheads and stringers for damage............................................................ O O O

6. Inspect antenna mounts and electric wiring............................................................. O O O

7. Inspect air conditioning system for freon leaks....................................................... O O O

8. Inspect freon level in sight gauge of receiver-dehydrator. (Refer to chapter 2l.).... O O O O

9. Inspect air conditioning condenser air scoop rigging ............................................. O O O O

l0. Inspect fuel lines, valves, and gauges for damage and operation............................ O O O

l l. Clean screens in fuel pumps ................................................................................... O O O

l2. Remove, drain, and clean fuel strainer bowl and screen. Drain and clean

at least every 90 days............................................................................................... O O O O

l3. Inspect security of all lines...................................................................................... O O O

l4. Inspect vertical fin and rudder surfaces for damage................................................ O O O

l5. Inspect rudder hinges, horn, and attachments for damage and operation................ O O O

l6. Inspect rudder control stop to insure stop has not loosened

and locknut is tight................................................................................................... O O O

17. Inspect vertical fin attachments............................................................................... O O O

18. Inspect rudder hinge bolts for excess wear. (Replace as required.)......................... O O O

19. Inspect stabilator surfaces for damage..................................................................... O O O

20. Inspect stabilator, tab hinges, horn, and attachments for damage and operation..... O O O

21. Inspect stabilator attachments. (See latest revision of Piper Service

Bulletin 856)............................................................................................................ O O O

22. Inspect stabilator and tab hinge bolts and bearings for excess wear.

(Replace as required.).............................................................................................. O O O

23. Inspect stabilator control stop. Ensure stop has not loosened and jam nut is tight.. O O O

23a. Inspect stabilator trim mechanism........................................................................... O O O

24. Inspect fuselage wing attach fittings for corrosion, general condition and security.

(See latest revision of Piper Service Bulletin 977.)................................................. O O O

25. Inspect cables, aileron, rudder, stabilator, stabilator trim, turnbuckles, guides,

and pulleys for safety, damage, and operation (See Note 22).................................. O O O

26. Inspect all cable tensions (use tensiometer). (See Note l7.).................................... O O O

27. Clean and lubricate stabilator trim drum screw....................................................... O O

28. Clean and lubricate all exterior needle bearings...................................................... O

29. Lubricate per lubrication chart. (Refer to chapter l2.)............................................. O O O O

30. Inspect anti-collision light for security and operation............................................. O O O

50

500

1000

100

Inspection Time (HRS)

PIPER AIRCRAFT

PA-28-236

MAINTENANCE MANUAL

5 - 21 - 00

Page 5 - 06

Interim Revision: February 15, 1995

1B5

Loading...

Loading...