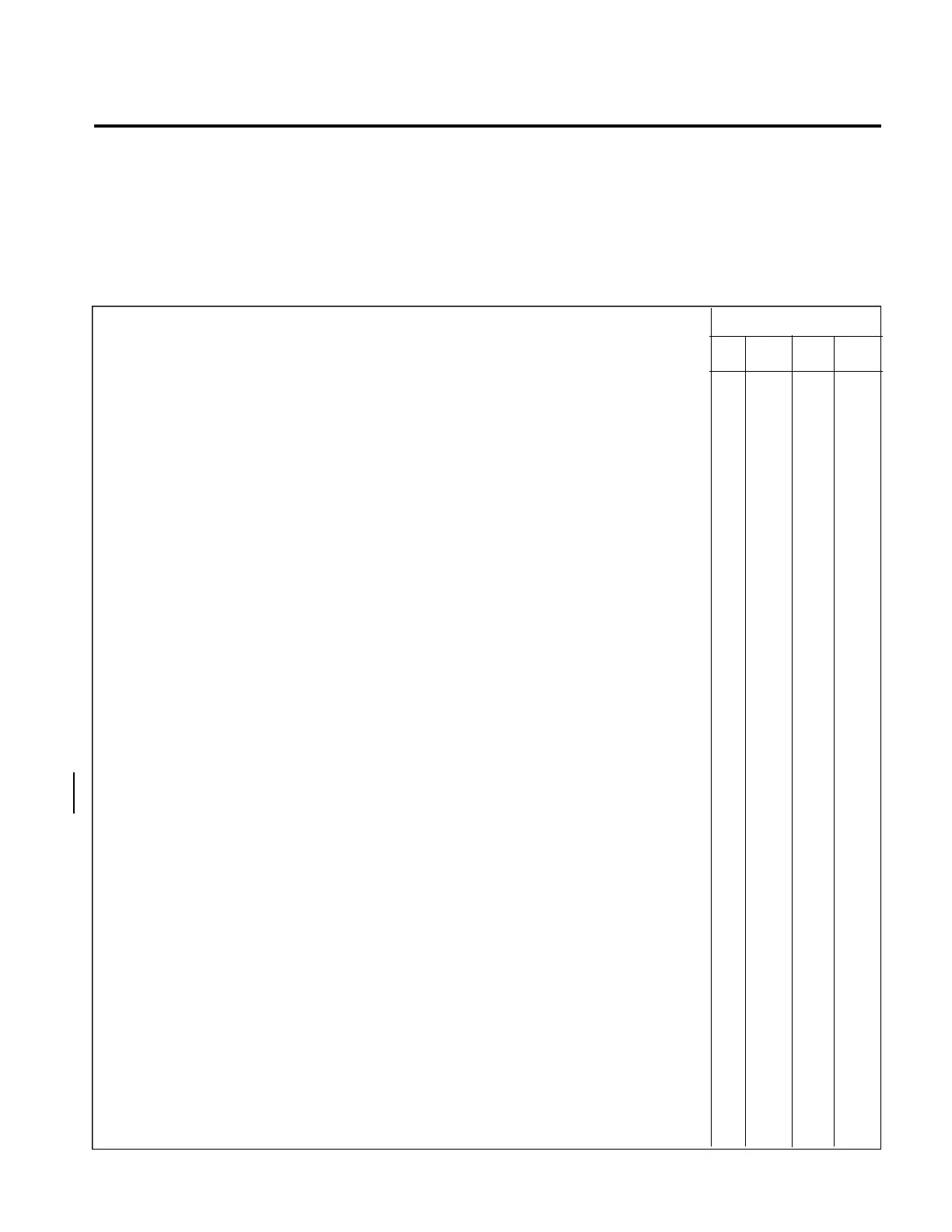

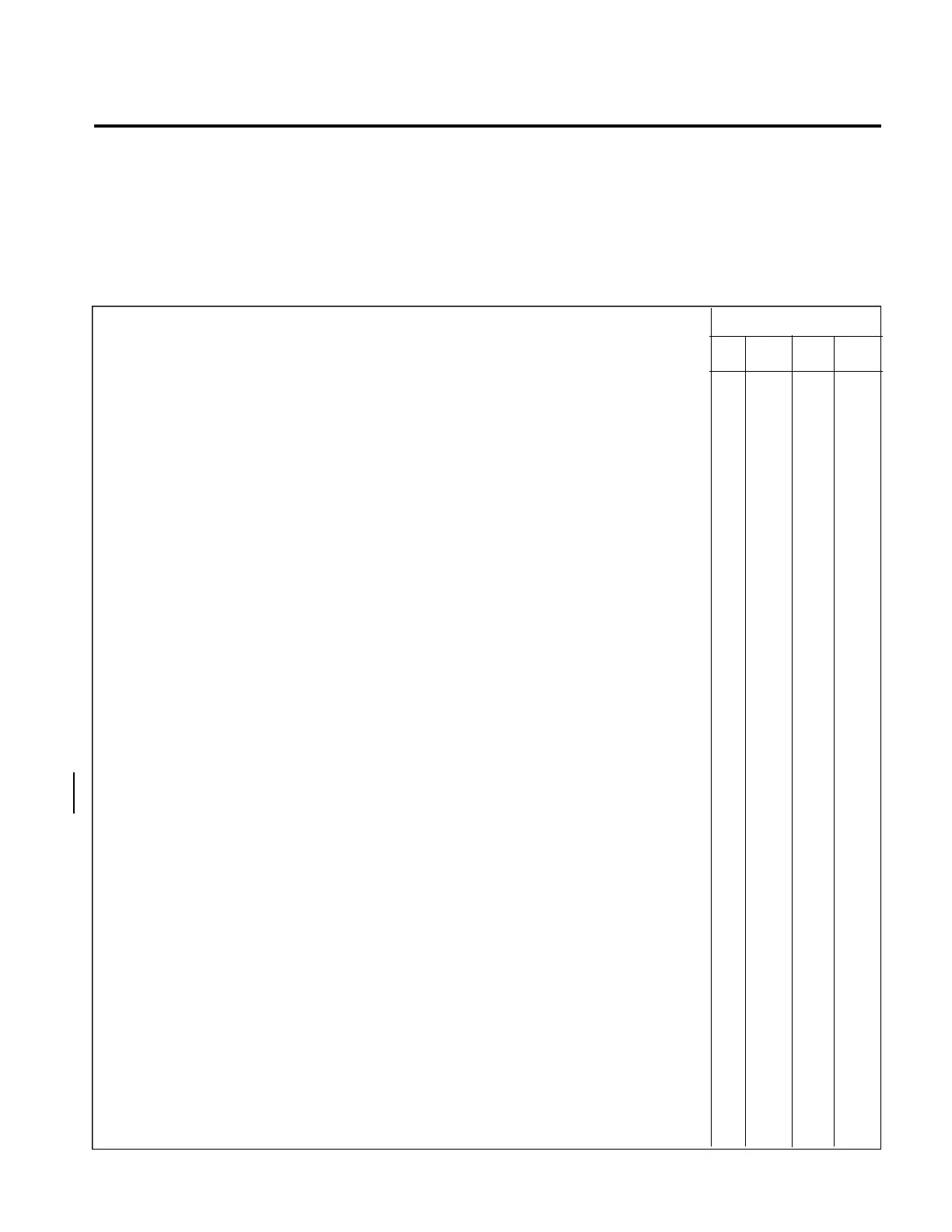

PERIODIC INSPECTIONS (cont)

—NOTE—

Perform all inspections or operations at each inspection interval as

indicated by a circle (O).

Nature of Inspection

D. FUSELAGE AND EMPENNAGE GROUP (cont)

31. Inspect security of Autopilot bridle cable clamps. (See Note 10.).......................... O O O

32. Inspect all control cables, air ducts, electrical leads, lines, radio antenna

leads, and attaching parts for security, routing, chafing, deterioration,

wear, and correct installation................................................................................... O O O

33. Inspect elt installation, condition of battery, and antenna. (See latest

revision of Piper Service Letter No. 820.)............................................................... O O O

34. Reinstall inspection plates and panels ..................................................................... O O O

E. WING GROUP

l. Remove inspection plates and fairings.................................................................... O O O

2. Inspect surfaces and tips for damage, loose rivets, and condition of

walkway................................................................................................................... O O O

3. Inspect aileron hinges and attachments .................................................................. O O O

4. Inspect aileron control stops to insure stop has not loosened and locknut

is tight ...................................................................................................................... O O O

5. Inspect aileron cables, pulleys, and bellcranks for damage and operation.............. O O O

6. Inspect flaps and attachments for damage and operation ....................................... O O O

7. Inspect condition of bolts used with hinges. (Replace as required.) ....................... O O O

8. Lubricate per lubrication chart. (Refer to chapter l2.) ............................................ O O O O

9. Inspect forward and aft wing attach fittings for corrosion, general condition and

security. (See latest revision of Piper Service Bulletin 977.)................................... O O O

9a. Inspect wing attachment bolts and brackets ............................................................ O O O

10. Inspect fuel tanks and lines for leaks and water. (See Note l6.) ............................. O O O

11. Fuel tanks marked for capacity ............................................................................... O O O

12. Fuel tanks marked for minimum octane rating........................................................ O O O

13. Inspect fuel cell vents. (See Note l5.) ..................................................................... O O O

14. Inspect all control cables, air ducts, electrical leads, lines, and attaching

parts for security, routing, chafing, deterioration, wear, and correct

installation ............................................................................................................... O O O

15. Reinstall inspection plates and fairings ................................................................... O O O

F. LANDING GEAR GROUP

1. Inspect oleo struts for proper extension. (Check fuid level as required.) ............... O O O O

2. Inspect nose gear steering control and travel........................................................... O O O

3. Inspect wheels for alignment .................................................................................. O O O

4. Put airplane on jacks ............................................................................................... O O O

5. Inspect tires for cuts, uneven or excessive wear, and slippage ............................... O O O

50

500

1000

100

Inspection Time (HRS)

PIPER AIRCRAFT

PA-28-236

MAINTENANCE MANUAL

5 - 21 - 00

Page 5 - 07

Interim Revision: February 15, 1995

1B6

Loading...

Loading...