P

BD_1

,

P

BD_2

, P

BD_n

Data sheet data of the braking resistors

f Balancing factor for PDB (f = 0.8 (guide value); see also technical data

of converter and supply unit)

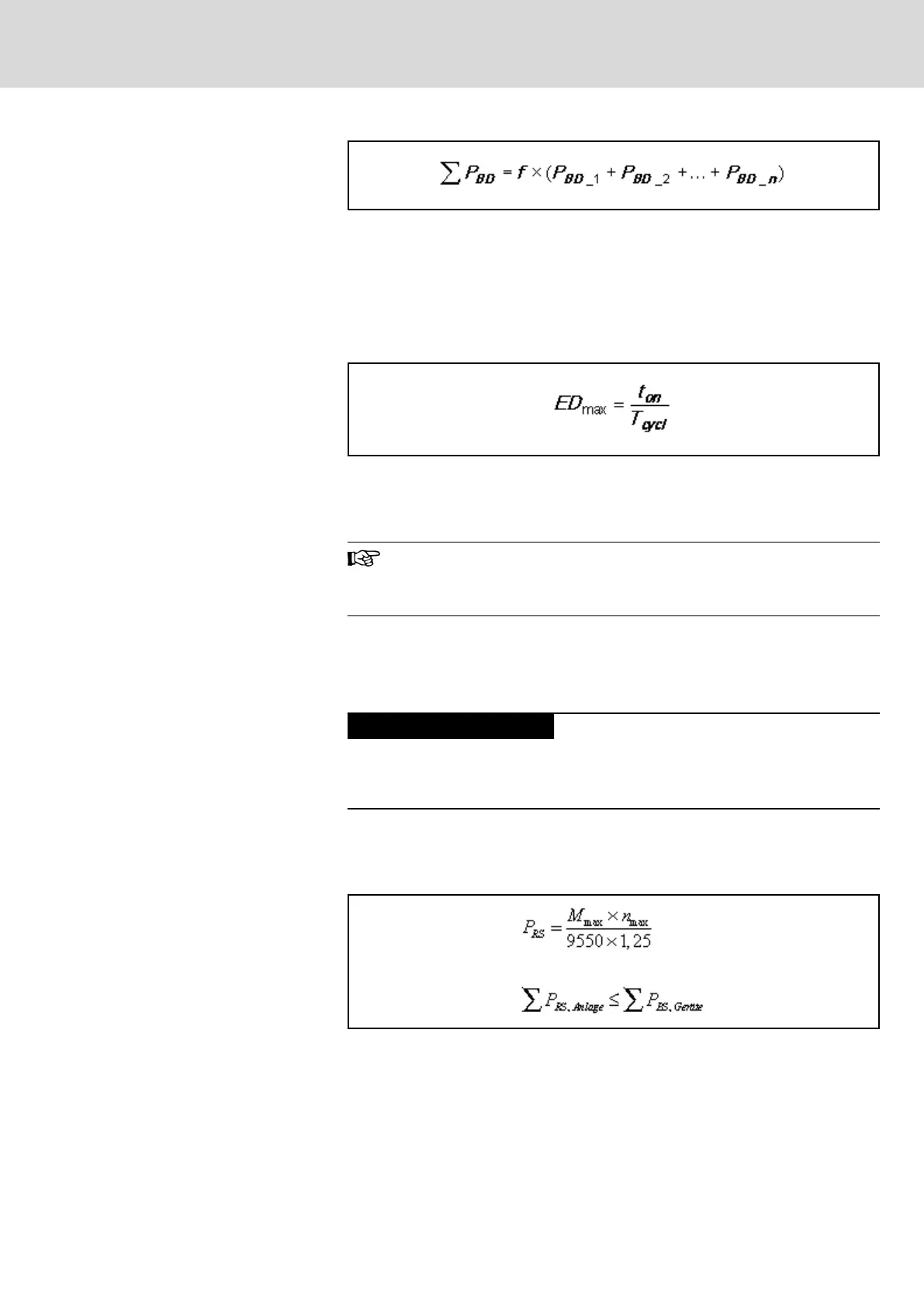

Fig.15-25: Sum of Braking Resistor Continuous Powers

Relative Duty Cycle of Braking Re‐

sistor

The quotient of t

on

and T

cycl

is understood by the duty cycle ED. The maxi‐

mum allowed relative duty cycle ED

max

is calculated from the nominal data for

HLR braking resistors:

ED

max

Maximum allowed relative duty cycle

t

on

Allowed duty cycle

T

cycl

Allowed cycle time

Fig.15-26: Relative Duty Cycle of Braking Resistor

Braking times

Within the indicated minimum cycle time T

cycl

, the braking resistor

may be switched on, as a maximum, for the time t

on

.

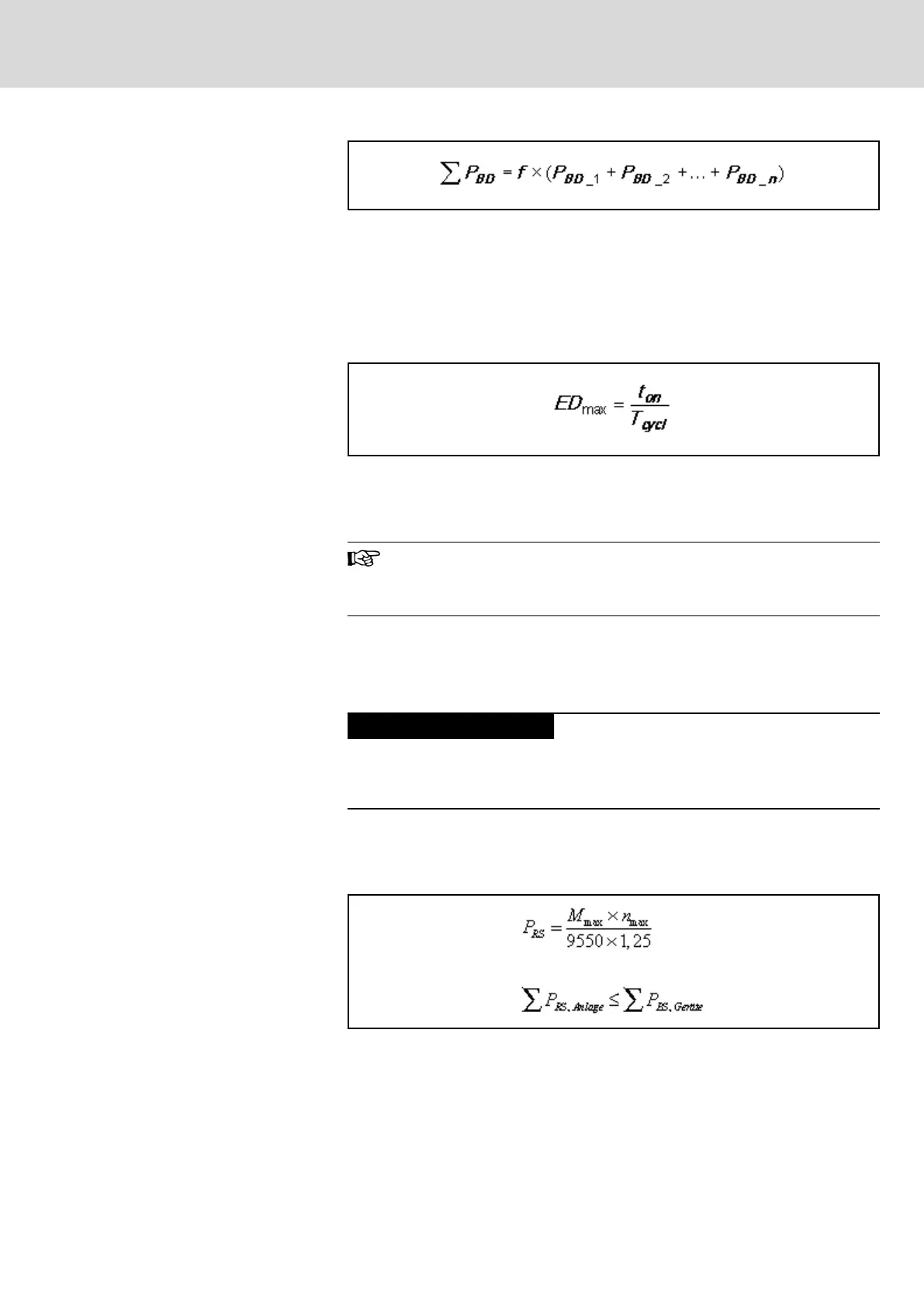

15.1.7 Peak Regenerative Power

Usually, peak regenerative power will occur when an E-Stop signal is trig‐

gered and all axes brake simultaneously.

Risk of damage due to extended braking

times and distances!

Select the supply unit such that the sum of peak regenerative powers of all

drives does not exceed braking resistor peak power of the supply unit.

See the respective motor selection data for the peak regenerative powers.

Peak regenerative power can be roughly calculated by the following equa‐

tion:

P

RS,Anlage

Generated peak regenerated power [kW]

P

BS,Geräte

Allowed braking resistor peak power [kW]

M

max

Maximum drive torque [Nm]

n

max

Maximum NC useful speed [min-1]

1,25 Constant for motor and controller efficiency

Fig.15-27: Peak Regenerative Power

DOK-INDRV*-SYSTEM*****-PR06-EN-P

Rexroth IndraDrive Drive Systems with HMV01/02 HMS01/02, HMD01, HCS02/03

Bosch Rexroth AG 257/309

Calculations

Loading...

Loading...