Manual – MOVIDRIVE® MDX61B Safety Module Option MOVISAFE® DCS..B

143

12

Typical response times

Appendix

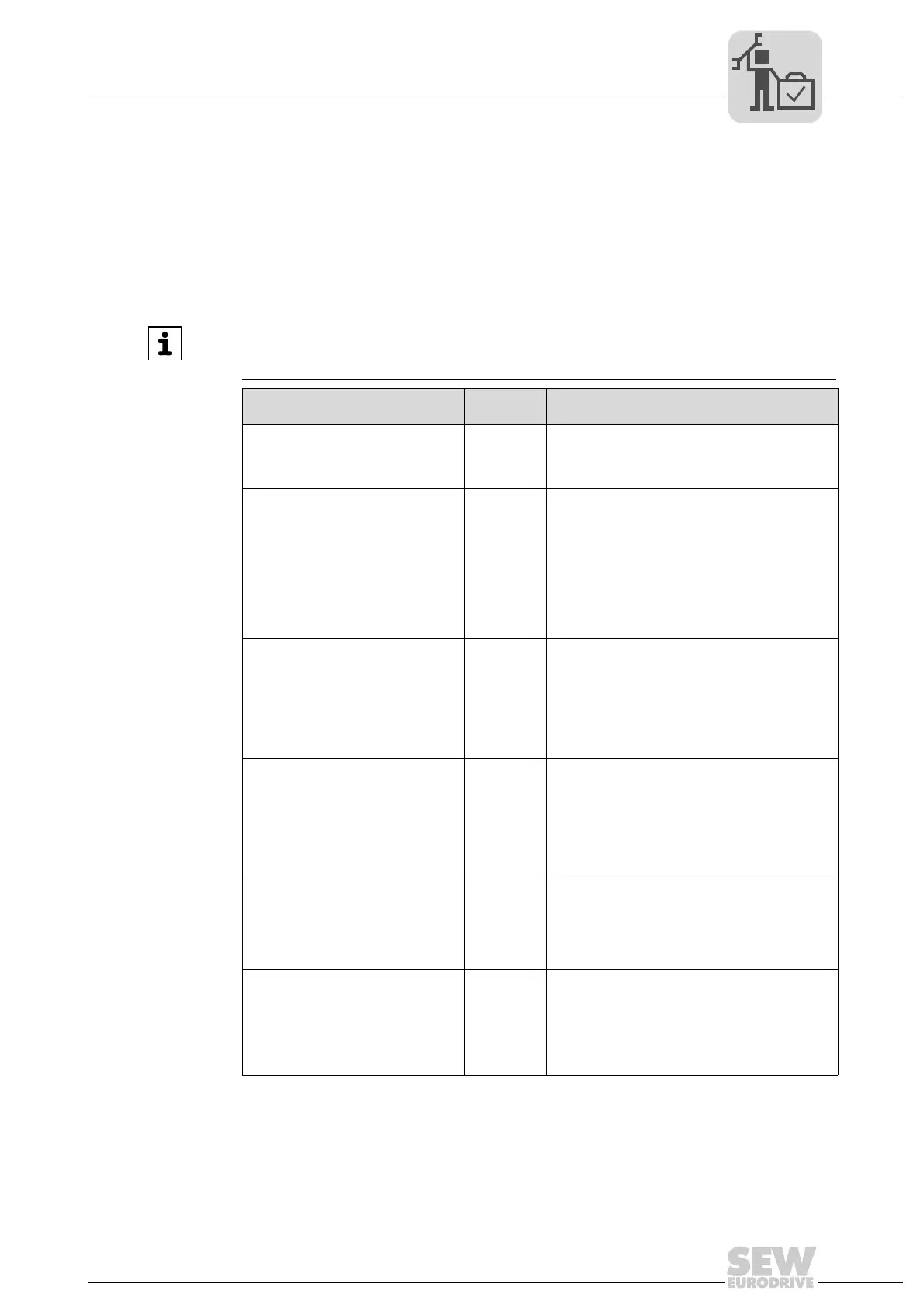

12.6.2 Typical response times of the DCS31B/32B option

The following table lists the response times of the DCS31B/32B option.

The calculation of response times is based on the cycle time of the system. The cycle

time (T_cycle) of the DCS31B/32B option is 25 ms. The specified response times cor-

respond to the maximum run time for the specific application within the DCS31B/32B

option. Depending on the application, additional application-specific response times for

the sensors and actuators used have to be added to obtain the total run time.

INFORMATION

If the "overspeed distance monitoring" filter is used, the response time will increase

depending on the set distance.

Function Response

time [ms]

Explanation

Reading-in a digital NC contact and

further processing by the internal

safety controller

58 The DCS31B/32B option recognizes an NC contact

within one cycle. Another cycle is needed for fur-

ther processing including the switching of an out-

put.

Reading-in a digital NO contact and

further processing by the internal

safety controller

75 For a NO contact to be recognized as active ("1"),

an active signal level must be present at the input

for an entire clock cycle of the DCS31B/32B

option. In the worst case, sampling will take two

cycles to make relevant information available for

internal processing. As another cycle is needed for

processing the input signal, this results in a total

signal run time of three cycles.

Note: Try to avoid using NO contacts in safety cir-

cuits!

Response of an already activated

monitoring function including logic

processing for position and speed pro-

cessing

50 For a monitoring function that has already been

activated via ENABLE, the DCS31B/32B option

needs one cycle to calculate the current speed

value. In the next cycle, the information is further

processed and output by the PLC after the monitor-

ing function has been calculated. This can lead, for

example, to the switching of an output once the

programmed logic has been performed.

Response of an already activated

monitoring function including logic

processing for acceleration process-

ing

75 For a monitoring function that has already been

activated via ENABLE, the DCS31B/32B option

needs two cycles to calculate the current accelera-

tion value. In the next cycle, the information is fur-

ther processed and output by the PLC after the

monitoring function has been calculated. This can

lead, for example, to the switching of an output

once the programmed logic has been performed.

Response of a monitoring function

activated by an external input includ-

ing processing of the safety controller

when using a NC contact.

83 Signal processing of an input lasts one scan cycle.

Another cycle is needed to set the ENABLE input

for the required monitoring function. In the next

cycle, the monitoring function and behavior of the

result is calculated and, if necessary, the output is

activated.

Response of a monitoring function

activated by an external input includ-

ing processing of the safety controller

when using a NO contact.

100 For processing the digital input signal, two cycles

are required in the worst case. Another cycle is

needed for setting the ENABLE input of the

required monitoring function. In the next cycle, the

monitoring function and processing of the result is

calculated and, if necessary, the output is acti-

vated.

Loading...

Loading...