22 FLOWSIC200 · Operating Instructions · 8013271/1CJ9/V 2-0/2022-01 · © SICK Engineering GmbH

Product description

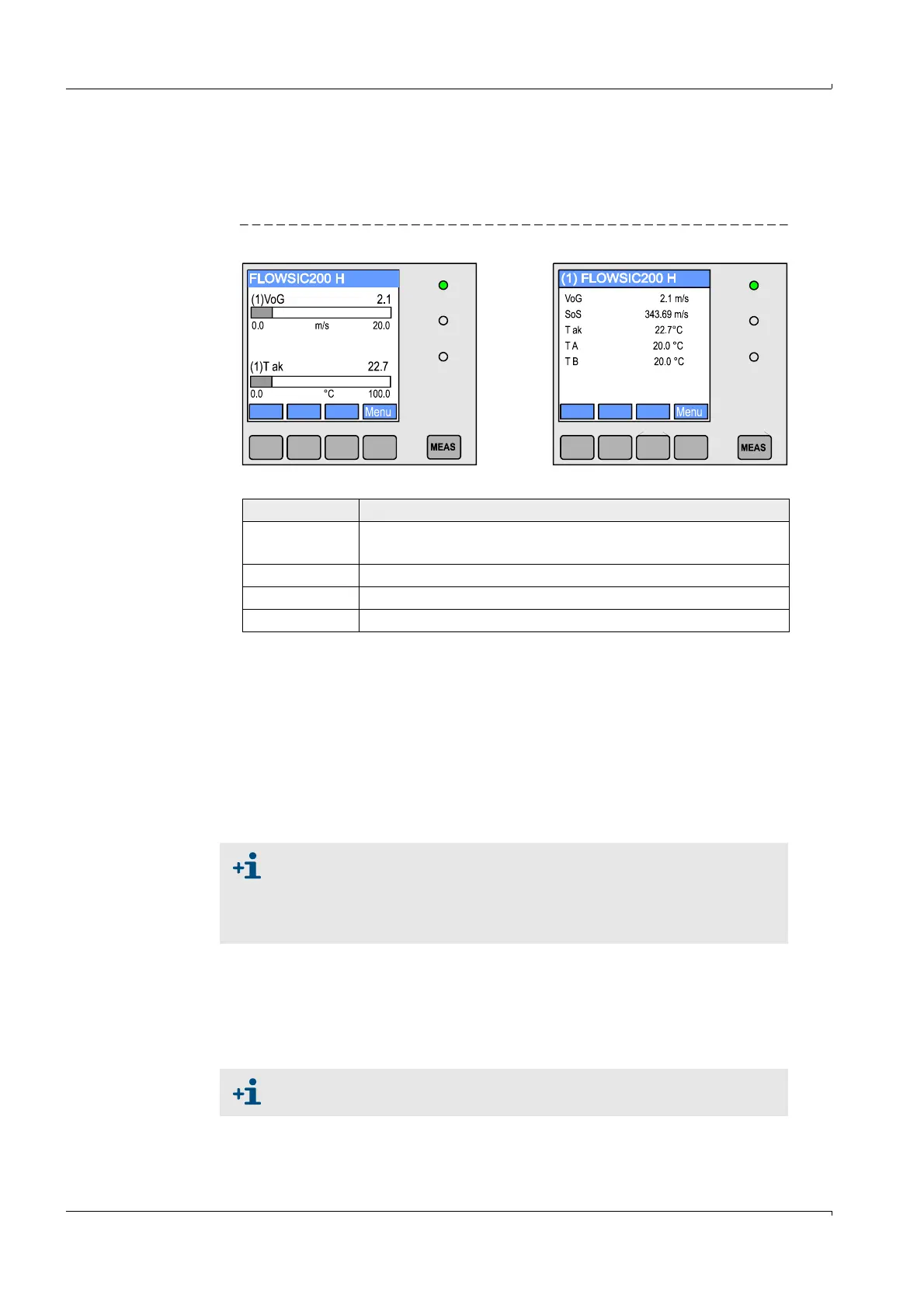

In the graphic display, two factory-preselected main measured values of a

connected sensor pair are shown in a bar graph. Alternatively, up to 8 single

measured values of a sender/receiver unit can be displayed (toggle with “Meas”

button).

Fig. 9 LC display with graphic (left) and text (right) display

– Control buttons

2 I/O module

For plugging onto module carrier (MCU in wall-mounted housing) or in slide-in module

(MCU in 19" housing), optionally as:

– Analog output module with 2 outputs 0/4 ... 22 mA to output further measured

variables (load 500 )

– Analog input module with 2 inputs 0/4 ... 22 mA to read in values from external

sensors

– Digital output module with 2 outputs (NC contact, contact load 48 V AC/DC, 5 A)

– Digital output module with 4 outputs (NO contact, contact load 48 V AC/DC, 0,5 A)

3 Interface module

Module to pass on measured values, system status and service information to higher

level control systems, optionally for Profibus DP V0, Ethernet or MODBUS, to plug onto a

hat rail (MCU in a wall housing) or slot (MCU in 19" housing). The module is connected

to the connection board with an associated cable.

Button Function

Meas

– Toggles between text and graphic display

– Displays the contrast settings (after 2.5 s)

Arrows Selects next/previous measured value screen

Status Displays alarm or error messages

Menu Displays main menu and selection of submenus

One module carrier is required per module (to plug in on the hat rail).

One module carrier has to be connected to the processor board with a

special cable, other module carriers can be docked to it.

A maximum of 8 I/O modules can be plugged in, of which a maximum of

4 modules of the same type.

Profibus DP-V0 for transfer via RS485 according to DIN 19245 Part 3 as

well as IEC 61158.

Loading...

Loading...