V800 Series High Performance Closed-Loop Vector Inverter User Manual

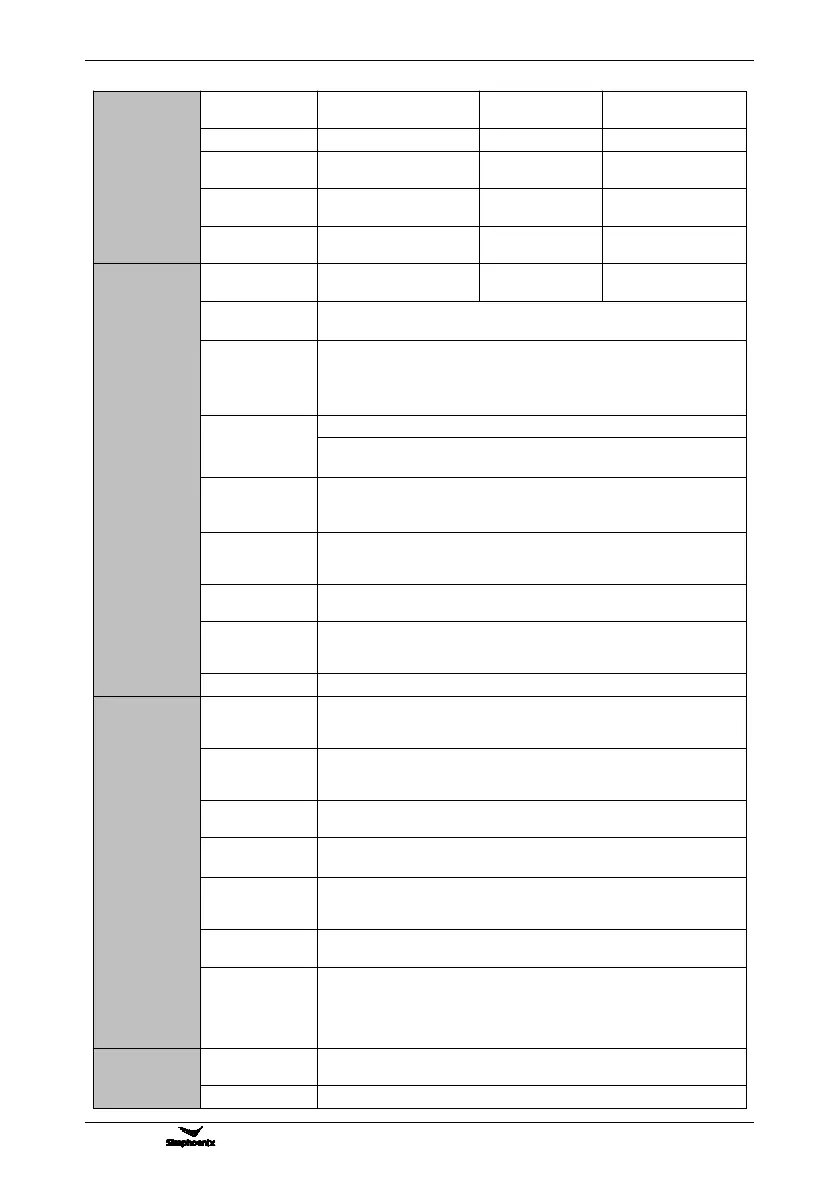

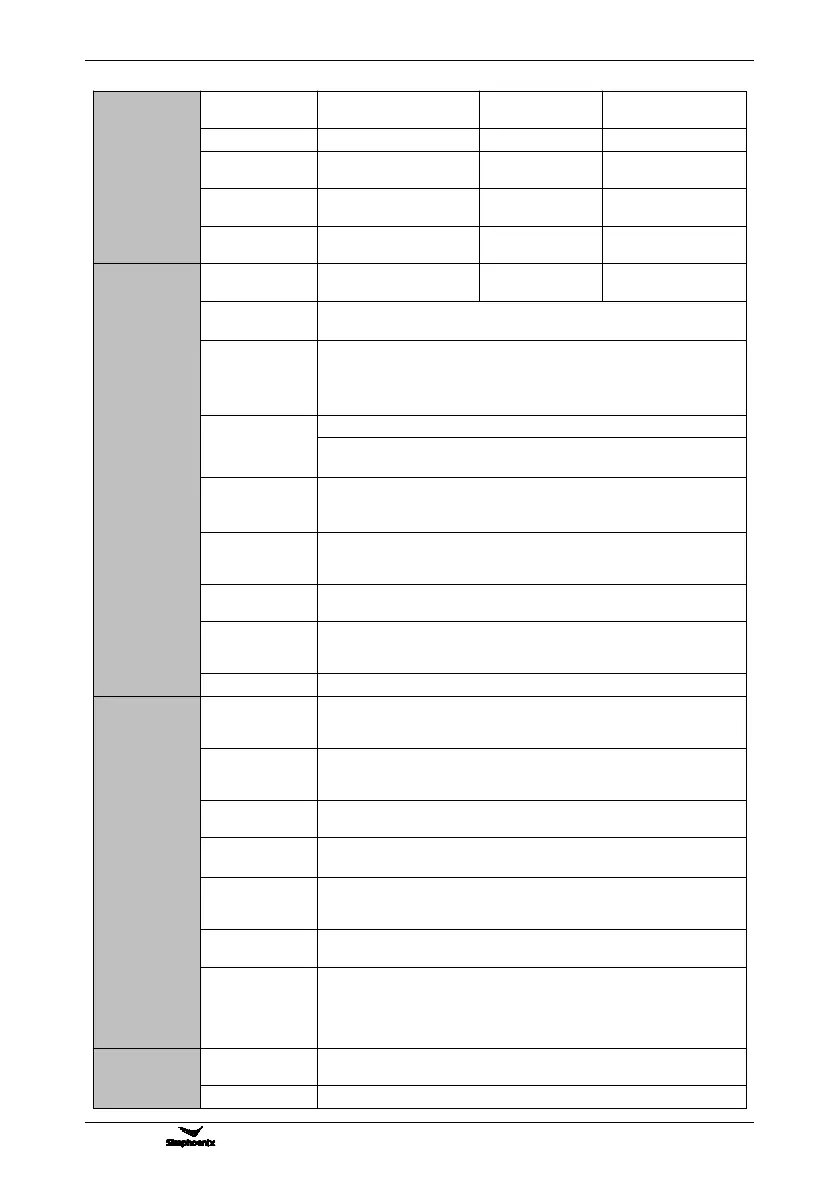

Closed-loop vector

control

Low frequency mode:0.01Hz;

High frequency mode:0.1Hz.

Low frequency mode:digital setting--0.01 Hz,

Analog setting - highest frequency ×0.1%

High frequency mode:digital setting--0.1 Hz,

Analog setting - highest frequency ×0.1%

Universal load mode: 110% - long-term; 150% - 60s; 180% -5s

Steady load mode (capacity increase mode): 105% - long-term;

120% - 60 s; 150% - 1 s

Two-phase vector composition:1.5~15.0KHz;

Three-phase vector composition: 1.5 ~ 12.0KHz (HIgh frequency

mode can reach 15KHz)

Deceleration

and acceleration

time

0.01 - 600.00Sec. / 0.01 - 600.0Min.

Achieve rapid retarding brake of the motor by increasing the motor's

magnetic flux (30-120% allowed)

DC brake/band-type brake initial frequency: 0.0 - upper limiting

frequency, brake/band-type brake injection current 0.0 ~ 100.0%

16-segment frequency/speed running, independent setting of the

running direction, time and acceleration and deceleration of each

segment; 7-segment process PID setting

Two built-in PID controller (process PID, compensation PID), can be

either used independently by external equipment or be used to create

complicated internal compensation control.

Process PID has simple sleeping and wakening functions.

Standard MODBUS communication protocol (optional) allowing for

flexible parameter reading and mapping

Able to receive detecting signals of PT100 or PTC thermo-sensitive

elements, hence allows for over-temperature protection for the motor or

external equipment.

(Standard configuration for models below V800-4T0220G/4T0300P)

Actuating voltage: 650~760V, braking ratio: 50~100%

Power cut restart; Fault self-recovery, motor parameter dynamic/static

self-identification. Start enabling, operation enabling, start delay, over

current suppression, over voltage/under voltage suppression, V/F

custom curve, analog input curve correction, line brake detection,

textile machinery disturbance (frequency swing) operation.

8-circuit one-to-one virtual output and input terminals, allowing for

complicated engineering onsite application in an easy way.

Allows for easy servo control and precision positioning of spindle angle.

Loading...

Loading...