Description Of Specific Functions

V800 Series High Performance Closed-Loop Vector Inverter User Manual

F0.0.12 Principal monitoring

parameter (H)

Setting range: d0.00~d0.55 /

d1.00~d1.55

F0.0.13 Auxiliary monitoring

parameter 1 (H)

Setting range: d0.00~d0.55 /

d1.00~d1.55

F0.0.14 Auxiliary monitoring

parameter 2 (H)

Setting range: d0.00~d0.55 /

d1.00~d1.55

This group of parameters is used to determine display contents on the operating panel at the status

monitoring mode, and bitwise operation must be followed for setting.

The Principal monitoring parameter is used to determine display contents on the main display column of

the LED panel, or the first display parameter on the LCD panel (signal parameter display).

The auxiliary monitoring parameter 1 is used to determine display contents on the auxiliary display column

of the LED panel, or the second display parameter on the LCD panel (dual parameter display) when the

inverter is running.

The auxiliary monitoring parameter 2 is used to determine display contents on the auxiliary display column

of the LED panel, or the third display parameter on the LCD panel (three parameter display) when the

inverter is stopped.

The corresponding physical quantity of the display data can be referred to the status monitoring parameter

table. When the inverter is conducting detection of motor parameters, the auxiliary display will display the

value of the current output current, which is not restricted by the parameter F0.0.13.

7.2 RUNNING COMMAND SELECTION (GROUP F0.1)

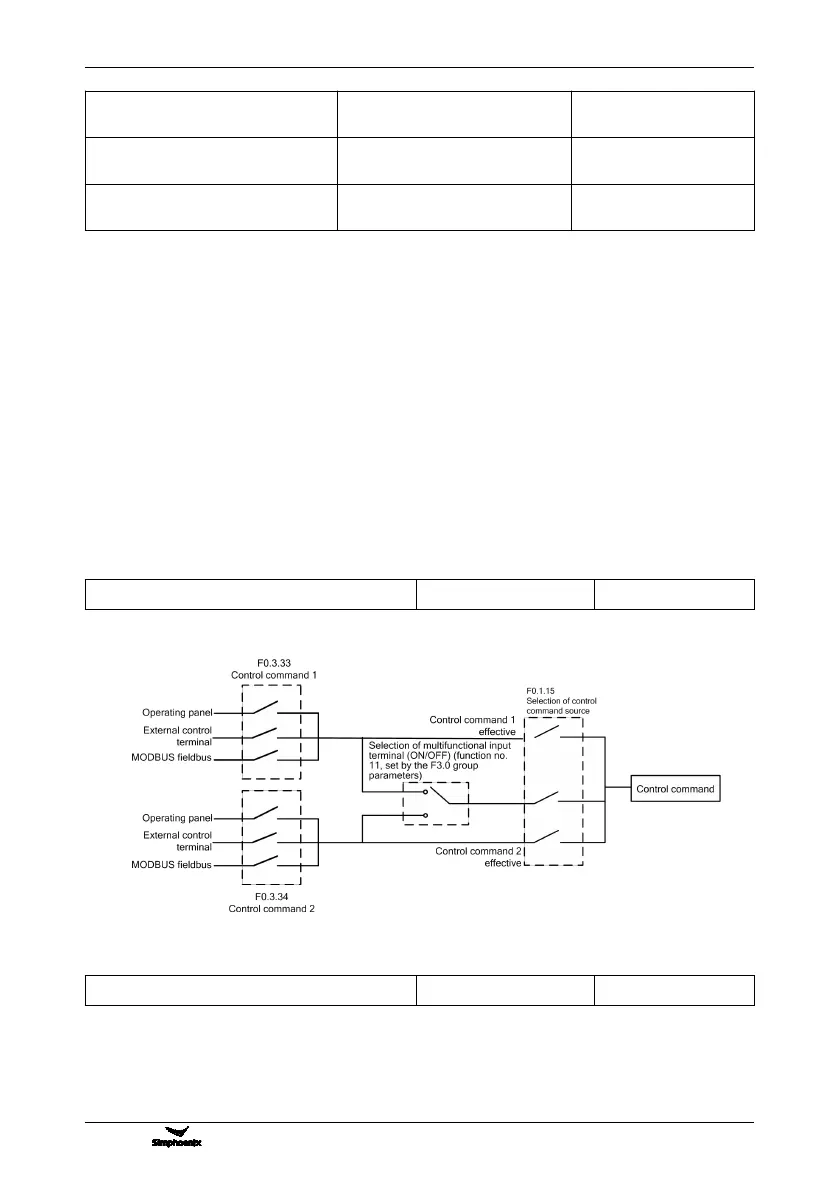

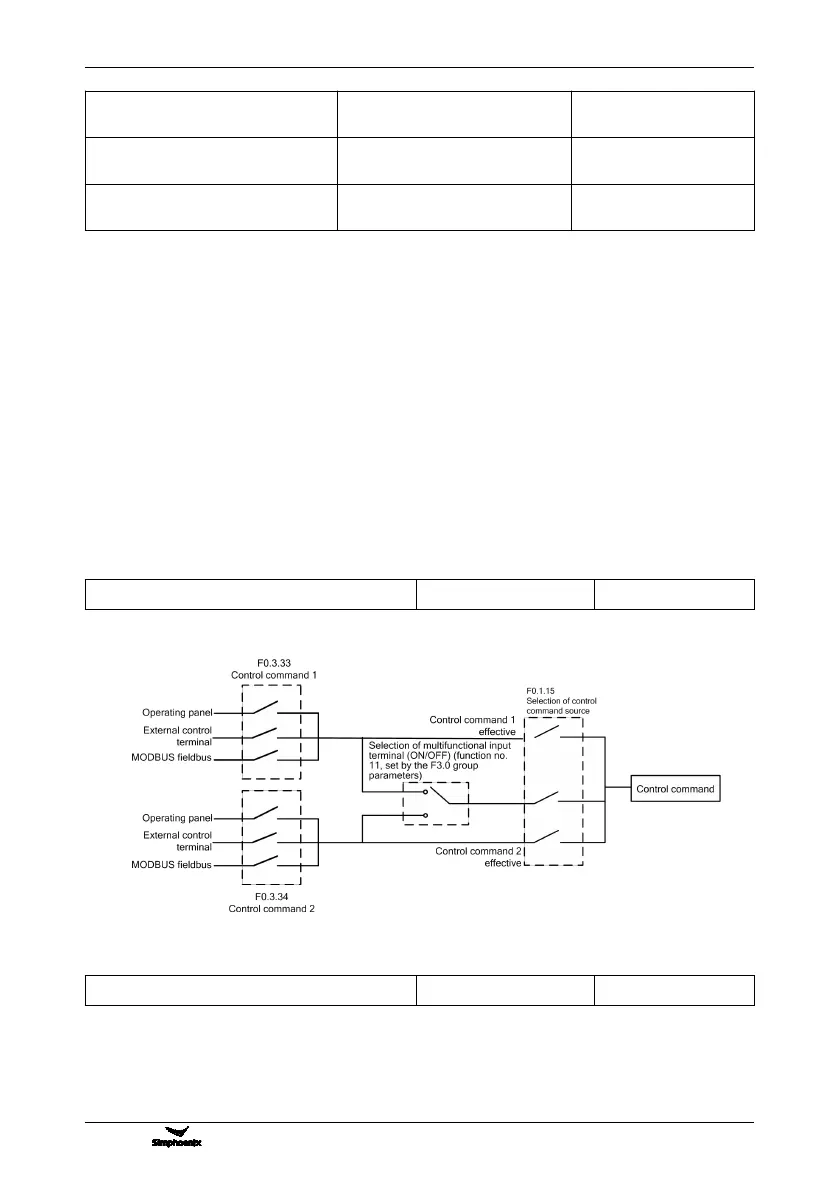

F0.1.15 Control place selection

This function defines three kinds of modes for selecting the control command source, as shown in Figure 7-7:

F0.1.16 Selection of frequency set value

The V800 series inverter has two frequency setting sources (corresponding parameters F0.2.25, F0.2.26).

This parameter determines 14 kinds of combined calculation methods for the two frequency setting sources.

Figure 7-8 shows the structure sketch of the frequency setting channel.

The actual running direction of the inverter is the result of “XOR” between the set value direction (always

Figure 7-7 Sketch of selecting the control command sources

Loading...

Loading...