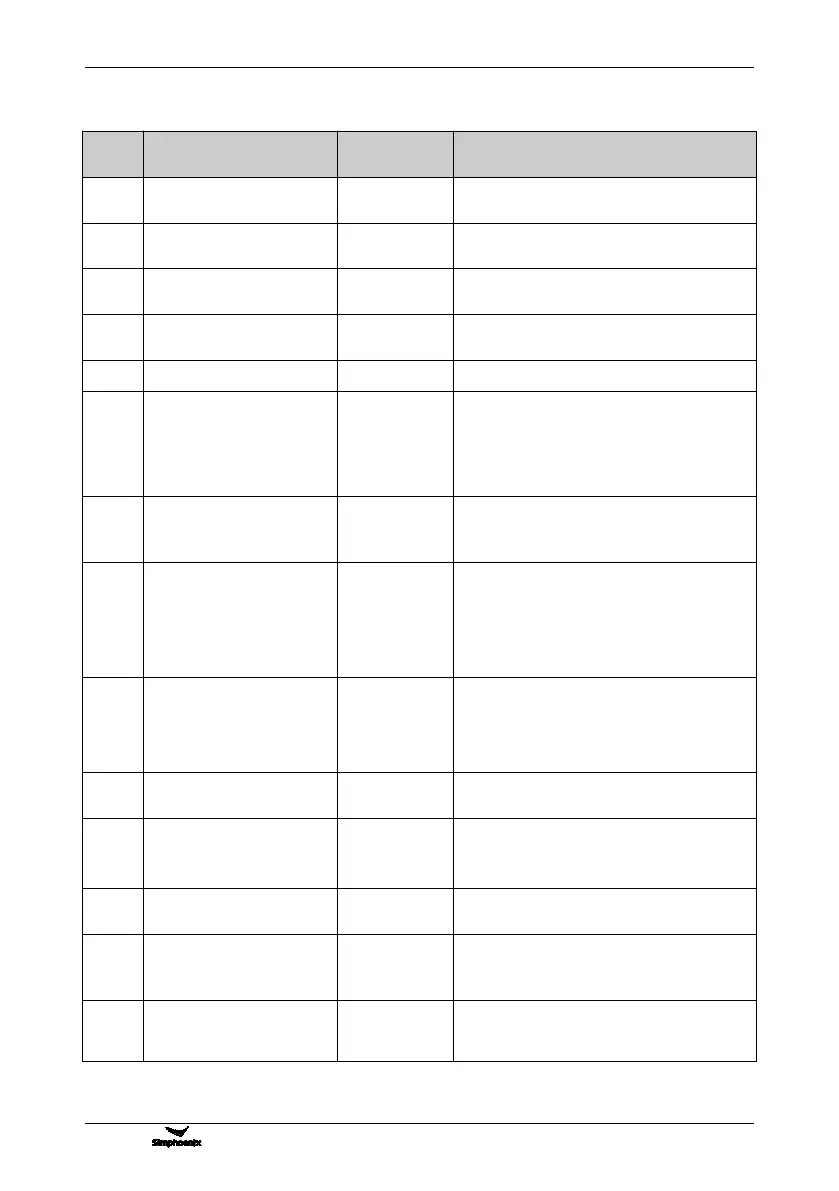

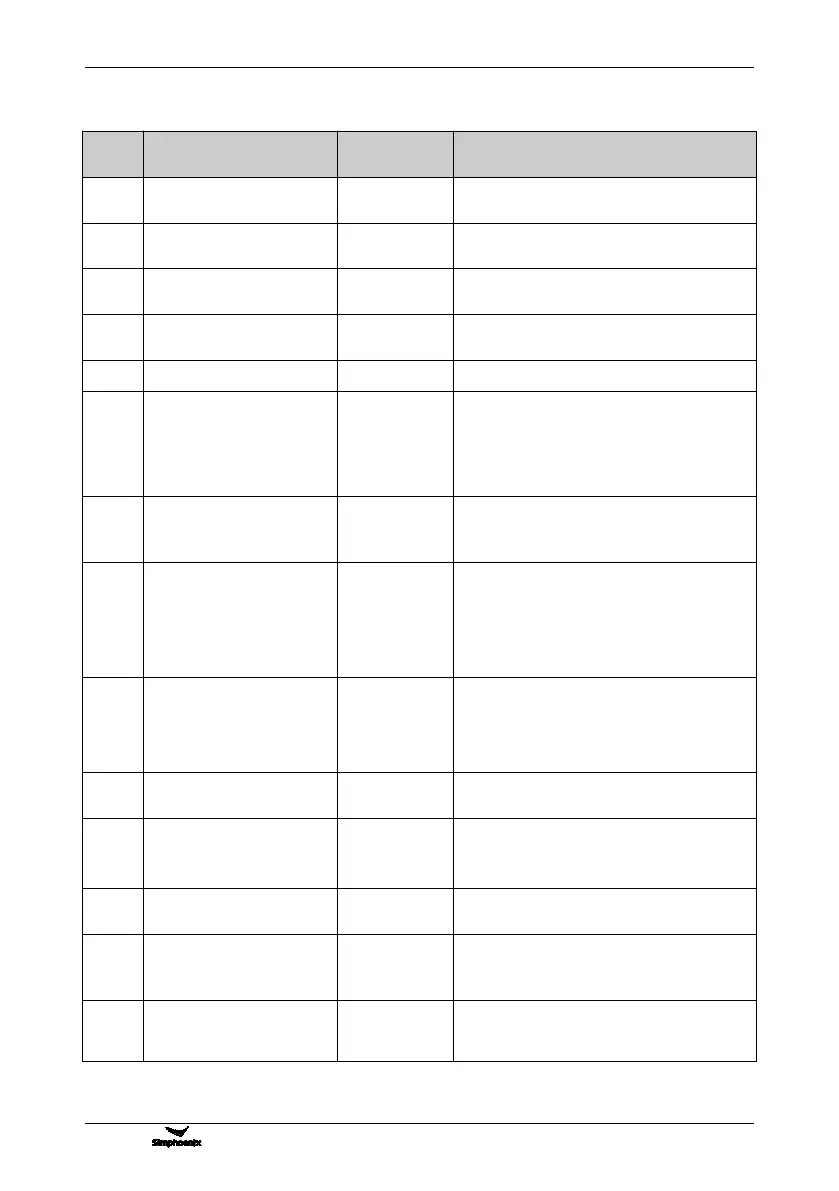

Warning, Alarm Diagnosis And Counter Measures

V800 Series High Performance Closed-Loop Vector Inverter User Manual

8.1.2 WARNING DISPLAY AND TROUBLESHOOTING

Solutions other than shielding

Over high power supply

voltage

Inspect input power supply

Lower input voltage (under

voltage early warning)

Inspect input power supply

Bad electromagnetic

environment

Improve working environment or seek for

manufacturer’s support

The load is overweight and

protection maybe occurred

Reduce load, or replace a frequency inverter with

larger power

INV overheating early warning

Improve ventilation conditions and reduce carrier

1. Reduce load

2. Prolong acceleration and deceleration time

3. Confirm mechanical system of load

4. Confirm the detection value ([F8.2.34]) and

time ([F8.2.35]) for DEV

1. Adjust frequency setting loop

2. Inspect the setting value of detection value

[F8.2.36]) and time ([F8.2.37]) for OS

The output current of U phase

is deficient/smaller

The output current of V phase

is deficient/smaller

The output current of W phase

is deficient/smaller

Inspect the connecting wire between frequency

inverter and motor or the winding of motor

The starting enabling signal is

deficient

1. Inspect the enabling connection (42) in

multifunctional input terminal and the status of

the terminal (ON/OFF)

2. Inspect whether the starting enabling signal in

bus command word is effective or not

Early warning of unbalanced

three-phase input voltage

Measure the input voltage of all the phases, install

ACR and reduce imbalance rate among phases

AI1 input is disconnected

AI2 input is disconnected

AI3 input is disconnected

1. Inspect the connection of analog input signal

2. Inspect whether there’re signals in the signal

source

Fin input is disconnected

(retained)

The rotating speed detecting

loop is disconnected

1. Inspect the connection of speed measuring

module

2. Seek for manufacturer’s support

No-load operation fails to

identify the parameters of

motor

Loading...

Loading...