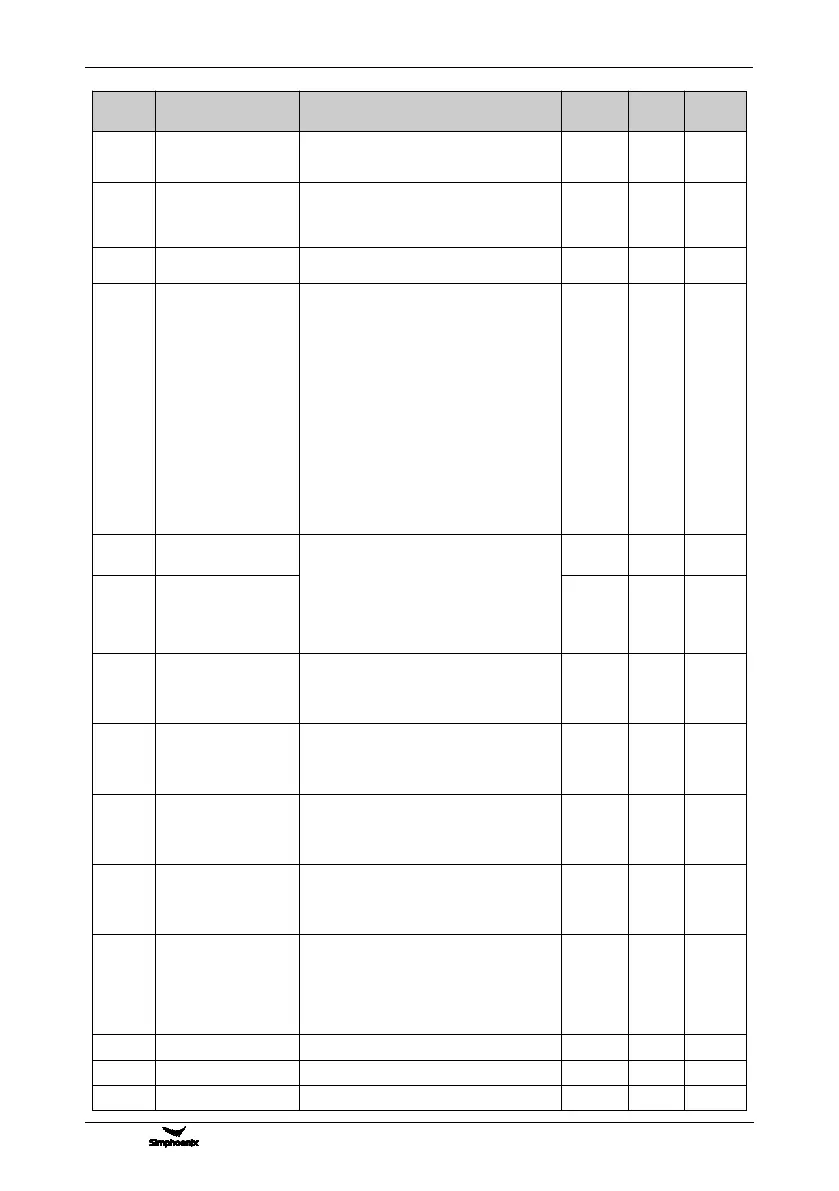

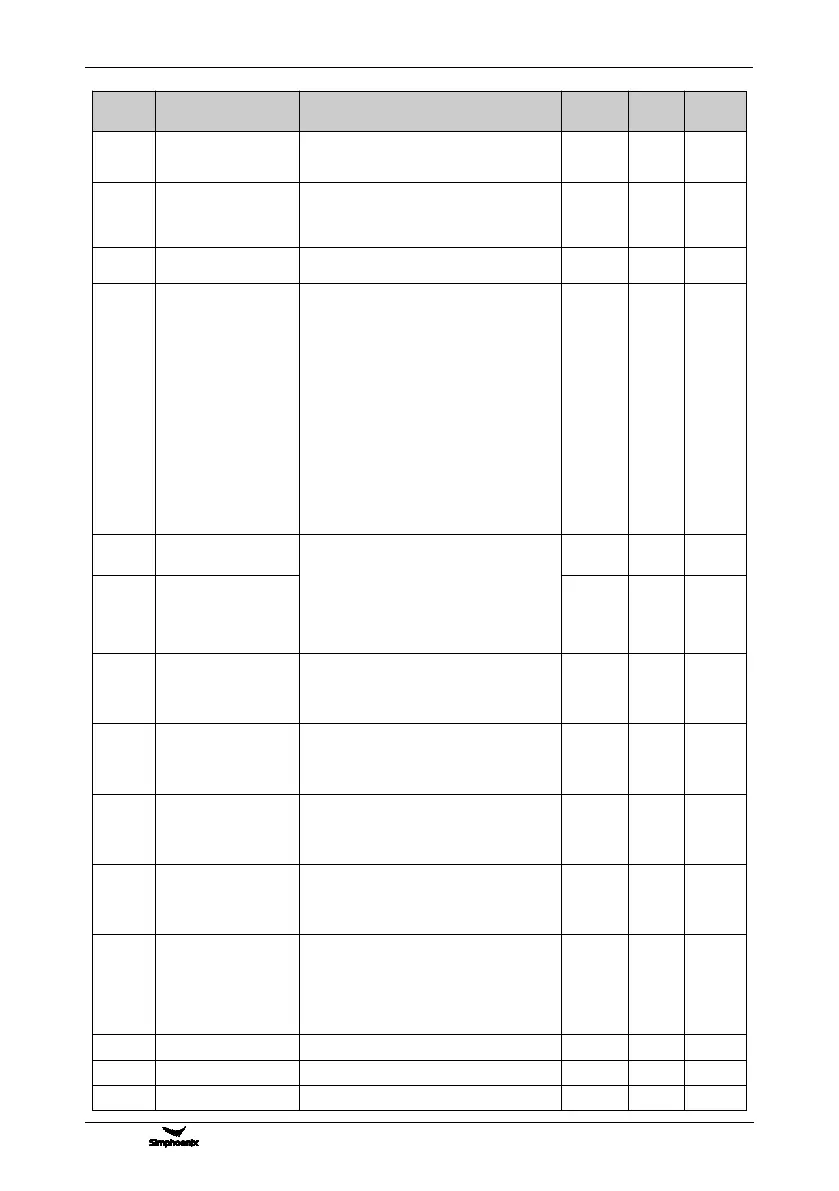

Functional Parameter Table

V800 Series High Performance Closed-Loop Vector Inverter User Manual

Setting Range and Description

Analog input quantity

corresponding to 0%

setting (Channel 2)

0.0V~[F7.0.07]/ AI2: 0.0mA~[F7.0.07]

Analog input quantity

corresponding to

100% setting

(Channel 2)

[F7.0.06]~10.00/AI2: [F7.0.06]~20.00mA

Process PID internal

digital preset

Process PID feedback

value selection

0: PID Actual Value 1

1: PID Actual Value 2

2: Select Via Remote Input (Function No.

32)

3: Actual Value 1+ Actual Value 2

4: Actual Value 1- Actual Value 2

5: Actual Value 1* Actual Value 2/100.0

6: 100.0* Actual Value 1/ Actual Value 2

7: Min. { Actual Value 1, Actual Value 2}

8: Max. { Actual Value 1, Actual Value 2}

9: √ (|Actual Value 1- Actual Value 2|)

10: √ (|Actual Value 1|) + √ (|Actual Value

2|)

Process PID feedback

channel 1

0: Analog input AI1

1: Analog input AI2

2: Analog input AI3

3: Analog input AI3 dual polarity PID

feedback

4: Fin pulse input

Process PID feedback

channel 2

Analog feedback

quantity corresponding

to 0% feedback

(feedback channel 1)

0.0~[F7.0.13] /AI2: 0.0mA~[F7.0.13]

Analog feedback

quantity corresponding

to 100% feedback

(feedback channel 1)

[F7.0.12]~10.00V /AI2: [F7.0.12]~20.00mA

Analog feedback

quantity corresponding

to 0% feedback

(feedback channel 2)

0.0~[F7.0.15]/AI2: 0.0mA~[F7.0.15]

Analog feedback

quantity corresponding

to 100% feedback

( feedback channel 2)

[F7.0.14]~10.00V /AI2: [F7.0.14]~20.00mA

Feedback

multiplication factor

(e.g. differential

voltage calculate flow

rate with differential

voltage)

Loading...

Loading...