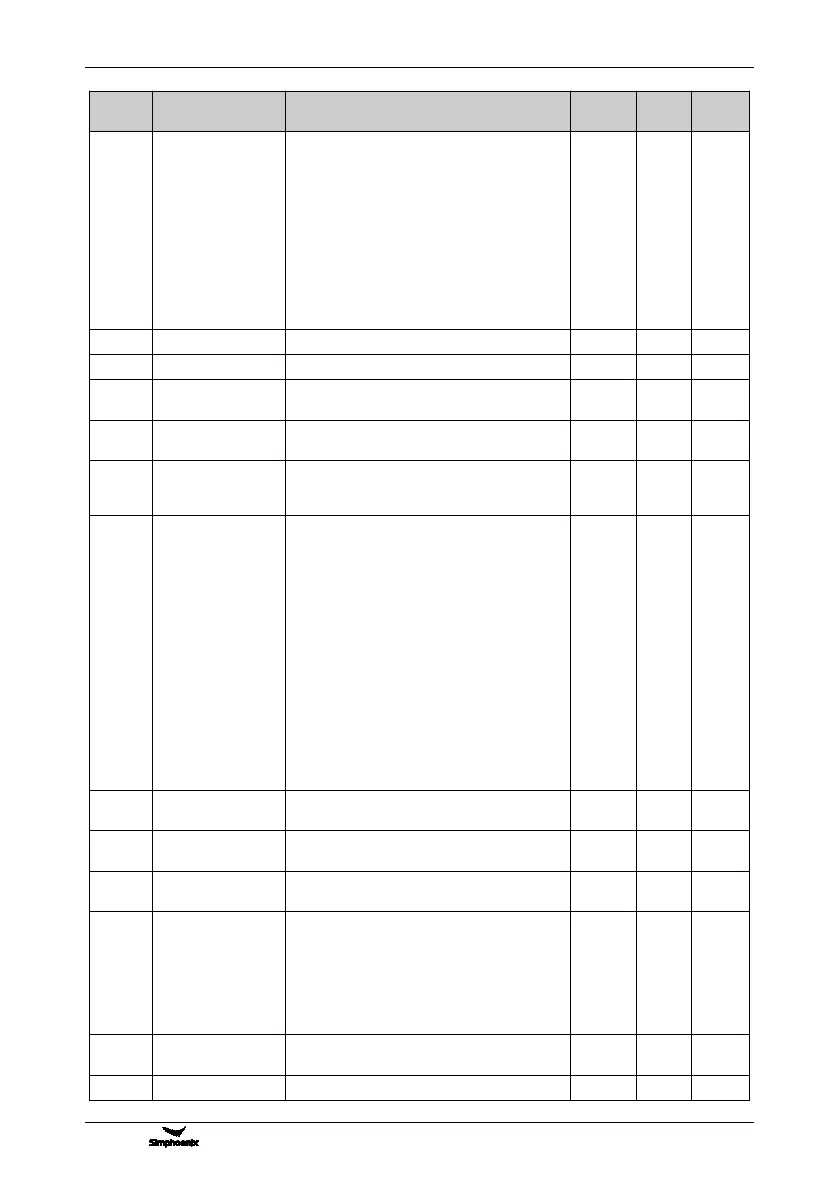

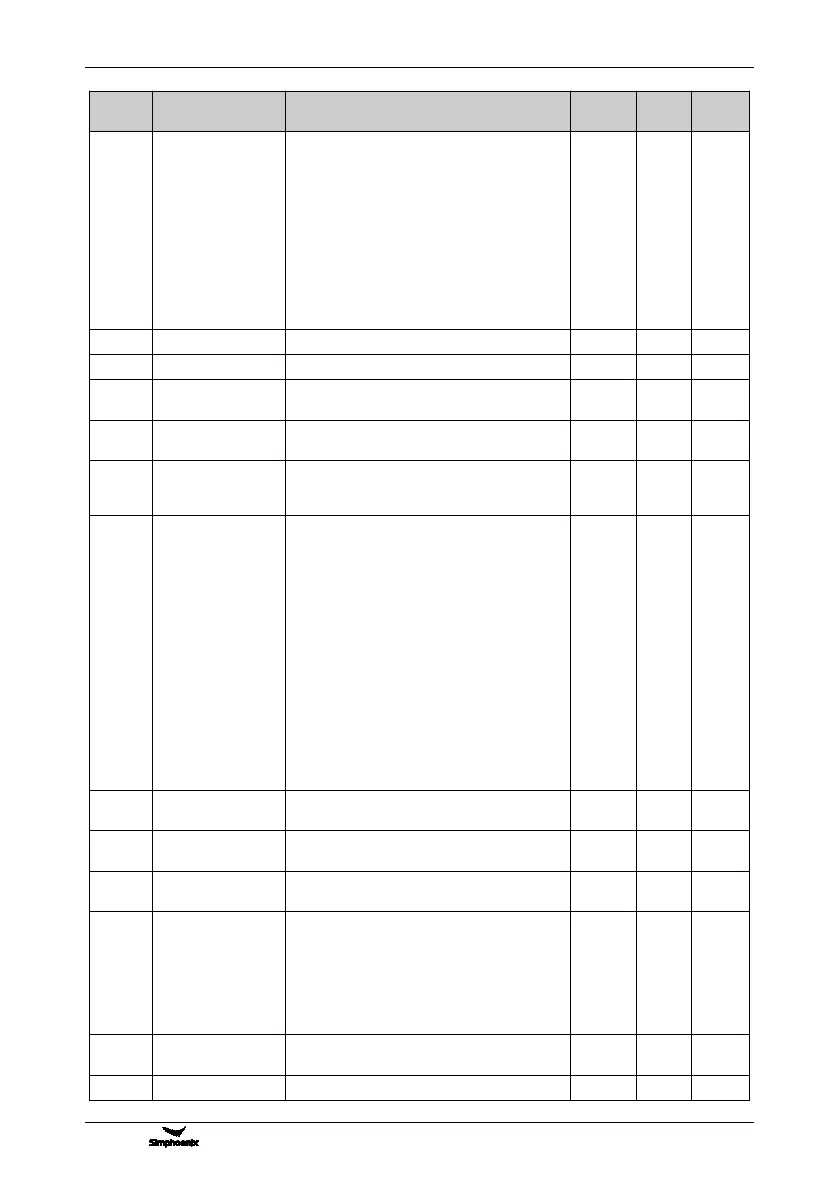

Functional Parameter Table

V800 Series High Performance Closed-Loop Vector Inverter User Manual

Setting Range and Description

Compensation PID

controller feature

configuration

_ _ _ X: Deviation polarity

0: Positive deviation

1: Negative deviation (negation)

_ _ X _: Output polarity

0: Single polarity

1: Dual polarity

_ X _ _:Loss of signal response

0: PID control closed

1: PID output held on (maintaining current

running setting)

Differential

coefficient 1

Differential inertia

filtering time 1

Compensation PID

output inertia filtering

time coefficient1

Selection of

compensation PID

set value

0: Internal digital setting (F9.0.11)

(auto save after power off)

1: Panel shuttle potentiometer preset value

2: Analog input AI1

3: Analog input AI2

4: Analog input AI3

5: UP/DW terminal (clear after stop)

6: UP/DW terminal (maintaining after stop and

save after power-off)

7: MODBUS Fieldbus set value 1

8: MODBUS Fieldbus set value 2

9: Expansion communication set 1

10: Expansion communication set 1

Analog input

minimum value

0.0V~[F9.0.10]/AI2: 0.0mA~[F9.0.10]

Analog input

maximum value

[F9.0.09]~10.00/AI2: [F9.0.09]~20.00mA

Selection of

compensation PID

feedback value

0: Analog input AI1

1: Analog input AI2

2: Analog input AI3

3: Output current

4: Output torque

5: Output power

Actual value analog

input minimum

0.0V~[F9.0.14]/AI2: 0.0mA~[F9.0.14]

[F9.0.13]~10.00/AI2: [F9.0.13]~20.00mA

Loading...

Loading...