Alignment

6-17

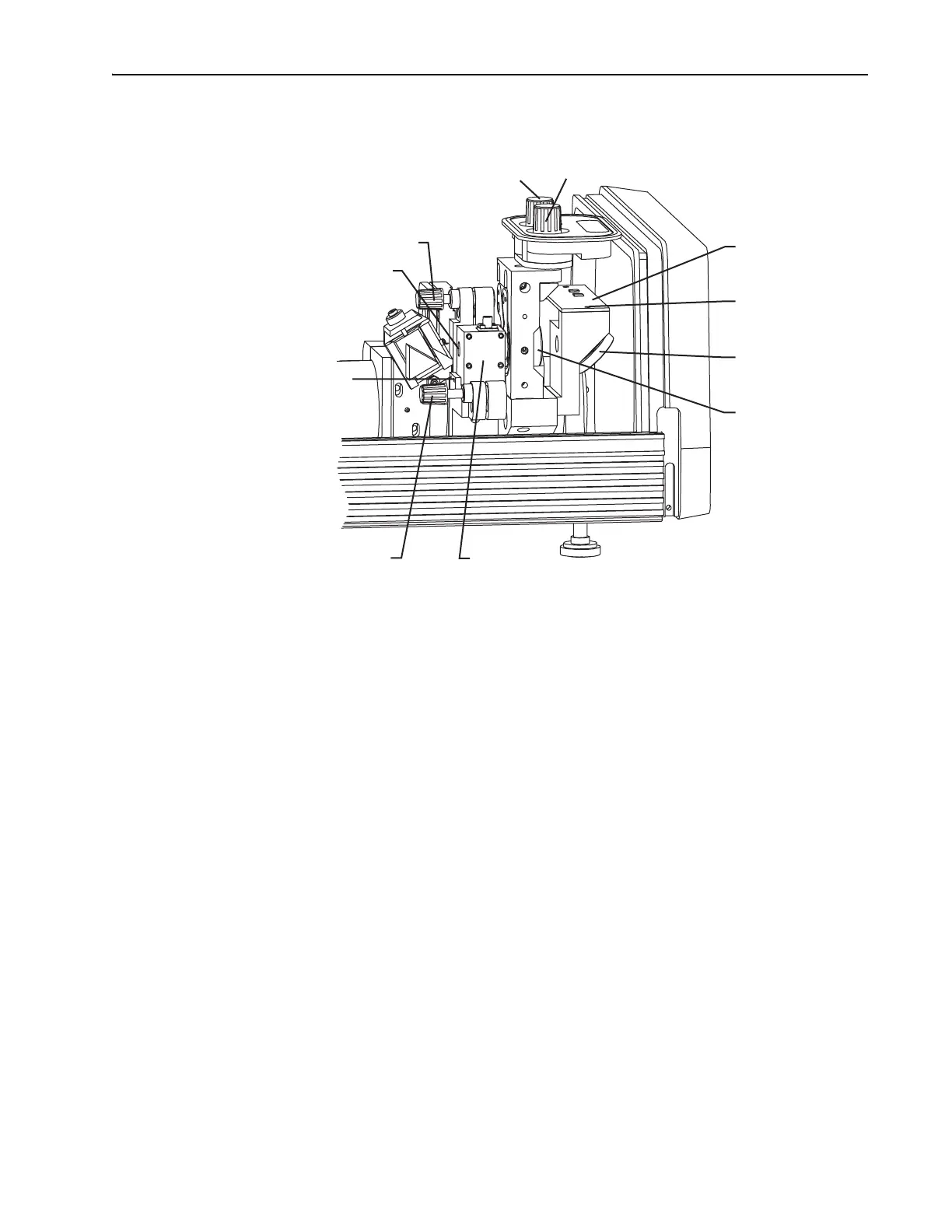

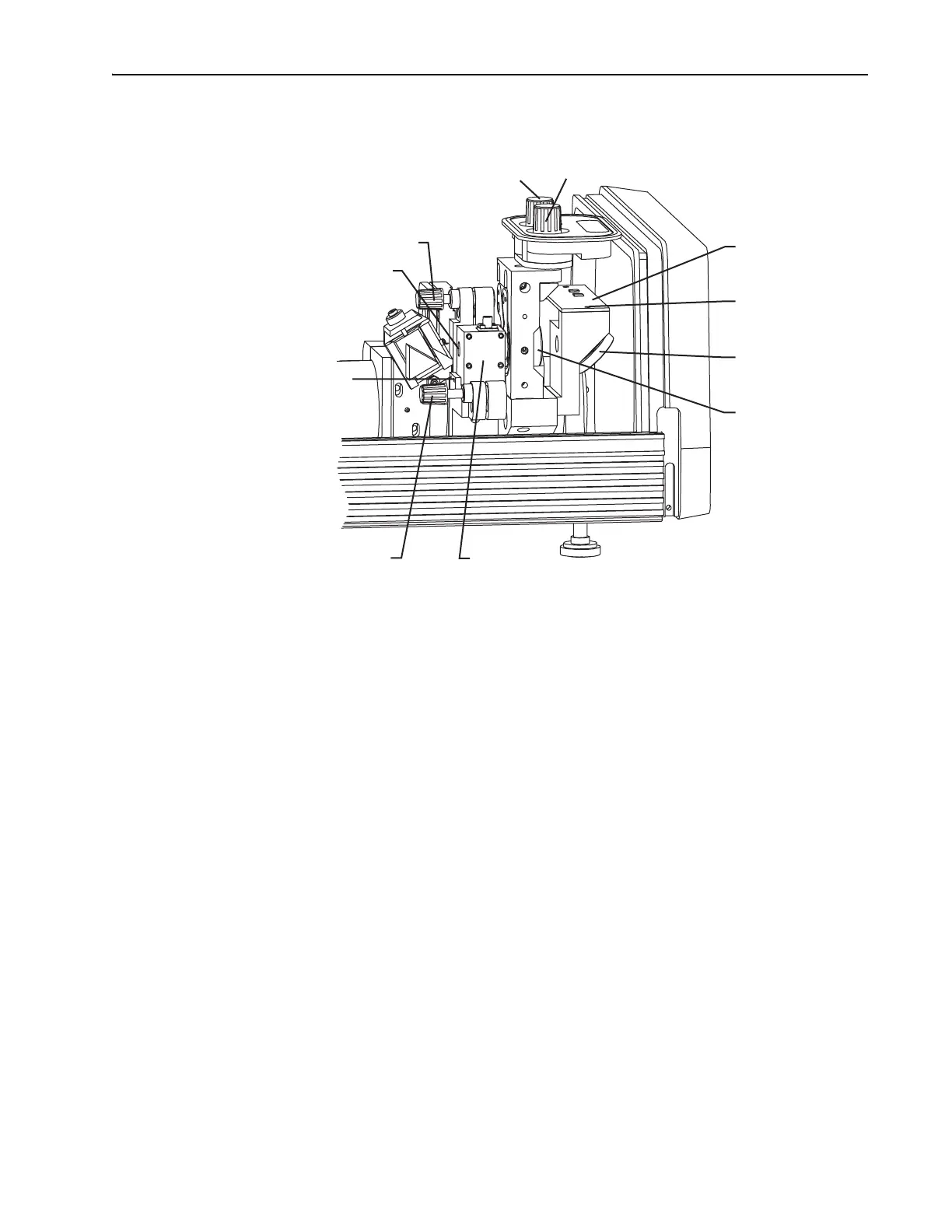

Figure 6-13: AOM, Output Coupler, Photodiode PC Board, and Beam Splitter

Place a white card between M

10

and the beam splitter, and use the edge

of the card to detect the position of the beam.

2. Use the vertical control knob of M

10

to detune the laser until it stops

lasing.

3. Verify the intracavity beam is centered in the AOM.

Use an IR viewer to see that the

M

3

/M

1

fluorescence is centered through

the silhouette of the AOM crystal. The fluorescence should not be near

the edges of the crystal. If necessary, loosen the

AOM mounting

bracket to adjust it vertically and horizontally. Two

2-56 setscrews hold

it horizontally while two

9

/64 in. cap screws keep it secured vertically.

4. Readjust M

10

vertically to reestablish lasing and to optimize output.

Establish Modelocking

1. Push the STATUS mode locker enable button (the ENABLE LED should

be on).

2. Set up an autocorrelator to aid in determining proper phase and GTI

POSITION dispersion compensation.

a. Increase the gain on the autocorrelator.

b. Adjust the crystal angle on the autocorrelator to obtain an oscillo-

scope signal trace (Figure 6-14, a–c).

Output Coupler (M

10

)

Positioning Controls

Horz. Vert.

Photodiode

PC Board

Mounting

Screws (2)

Beam

Splitter

Output

Coupler (M

10

)

AOM Pitch Control

AOM Aperture Window

AOM Mounting Setscrews (2)

AOM Horizontal

Angle Control

AOM

Loading...

Loading...