217

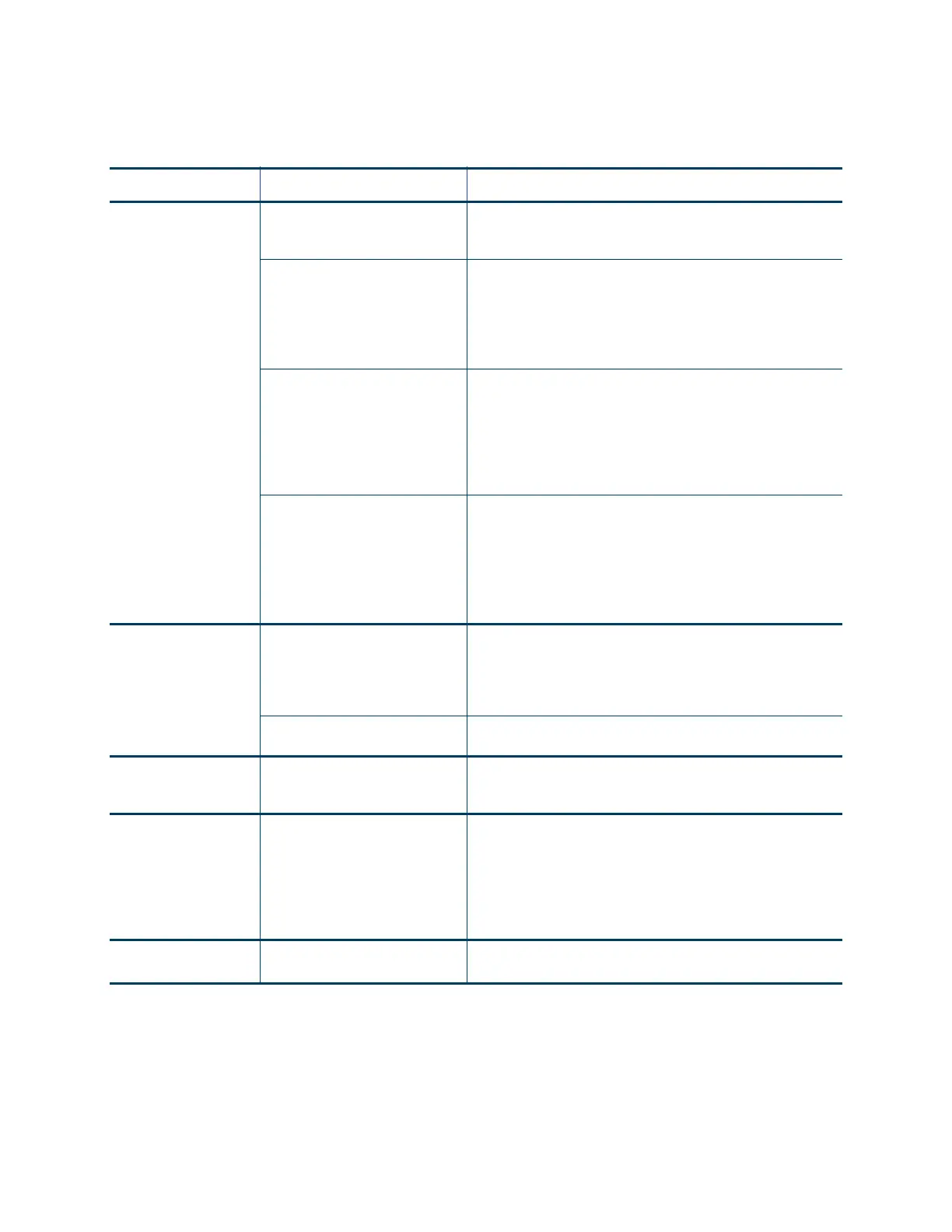

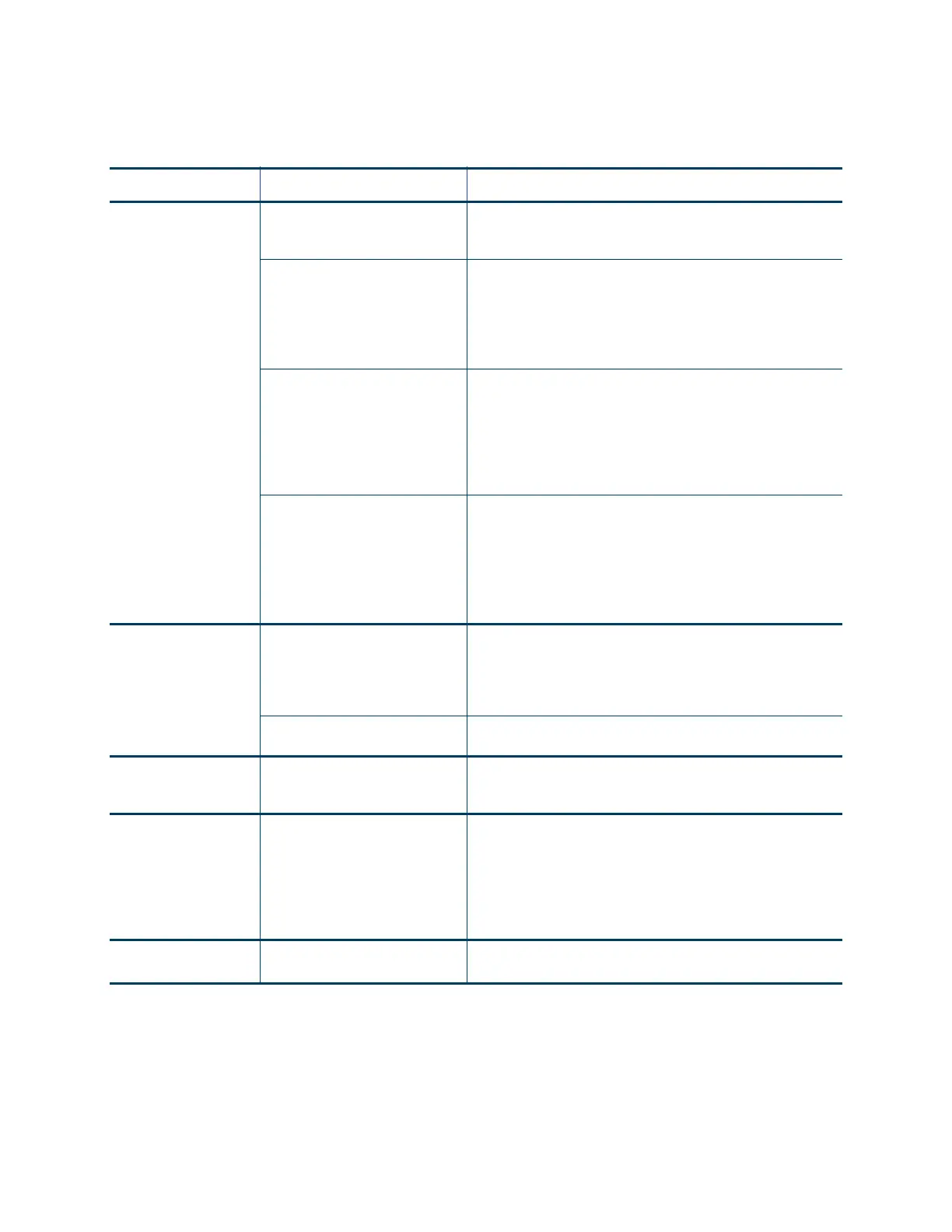

FINDING A REMEDY

The following table lists various troubleshooting scenarios you may encounter when operating the printer and

methods for resolving these scenarios.

Condition Possible Cause Remedy

Material spool will not

load

Empty material spool (zero

volume).

Remove and replace empty material spool (see “Removing

Material Spools” on page 114 and “Material Spool

Installation” on page 109).

Incorrect material spool type

installed.

The F123 Series utilizes a different material spool memory

chip than other Stratasys printers. As a result, only F123

Series material spools can be used to build parts on the

printer.

Ensure that an F123 Series material spool is installed.

Material spool memory chip

circuit failed.

View the spool’s associated Material Status Icon within the

Materials page. If the icon is red, there may be an issue with

the material spool’s memory chip. Unload and then reload

the spool. If the error persists, replace the spool with a new

one. See “Unloading Material” on page 113, “Removing

Material Spools” on page 114, and “Loading Material” on

page 108.

Filament does not reach head

(load time-out reached)

Remove material spool and replace with a new spool (see

“Removing Material Spools” on page 114 and “Loading

Material” on page 108).

If the error persists, contact Customer Support or your

regional Stratasys office (see “Getting Help” on page 204

for contact information).

Loss of extrusion

(head will not extrude

material)

Plugged Tips Verify that material purges by initiating a purge using the

model and/or support purge buttons. See “Head

Maintenance” on page 64.

Replace head with new head and recalibrate. See “Head

Replacement” on page 117.

Printer not calibrated Perform a Tip Offset Calibration. See “Tip Calibration” on

page 141.

Support material is

difficult to remove from

part

Support material is embedded in

the vertical surfaces of the part.

Adjust the Tip Offset Calibration. See “Manual Tip

Calibration” on page 144.

Model material surface

finish is poor on

downward facing

surfaces

Support material

removes too easily

The tip to tip calibration is not

set correctly.

Repeat Tip Offset Calibration. See “Manual Tip Calibration”

on page 144.

Material oozing Moisture in the material spool. Contact Customer Support or your regional Stratasys office

(see “Getting Help” on page 204

for contact information).

Loading...

Loading...