5-40 4252490-Rev A

HYDROSTATIC POWER TRAIN

5

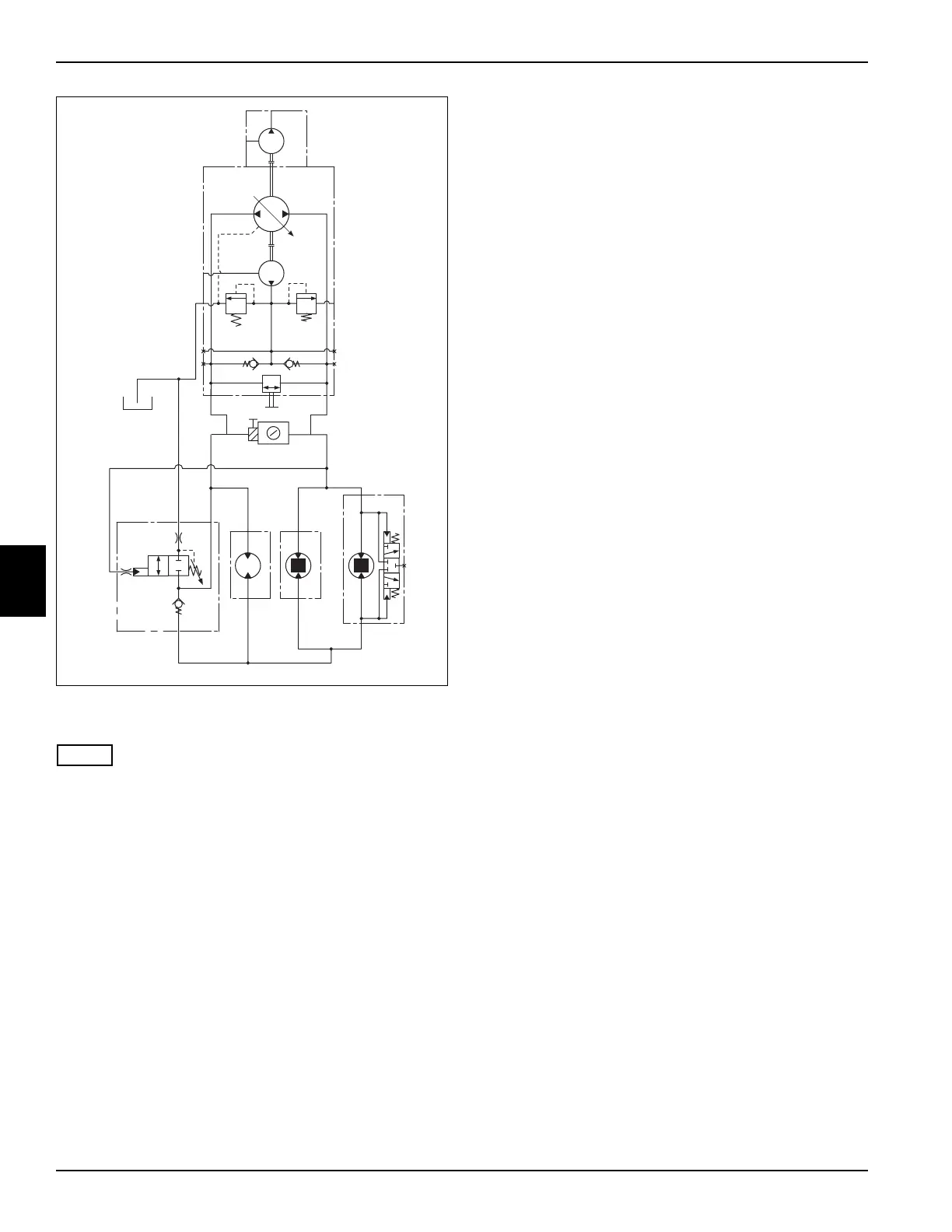

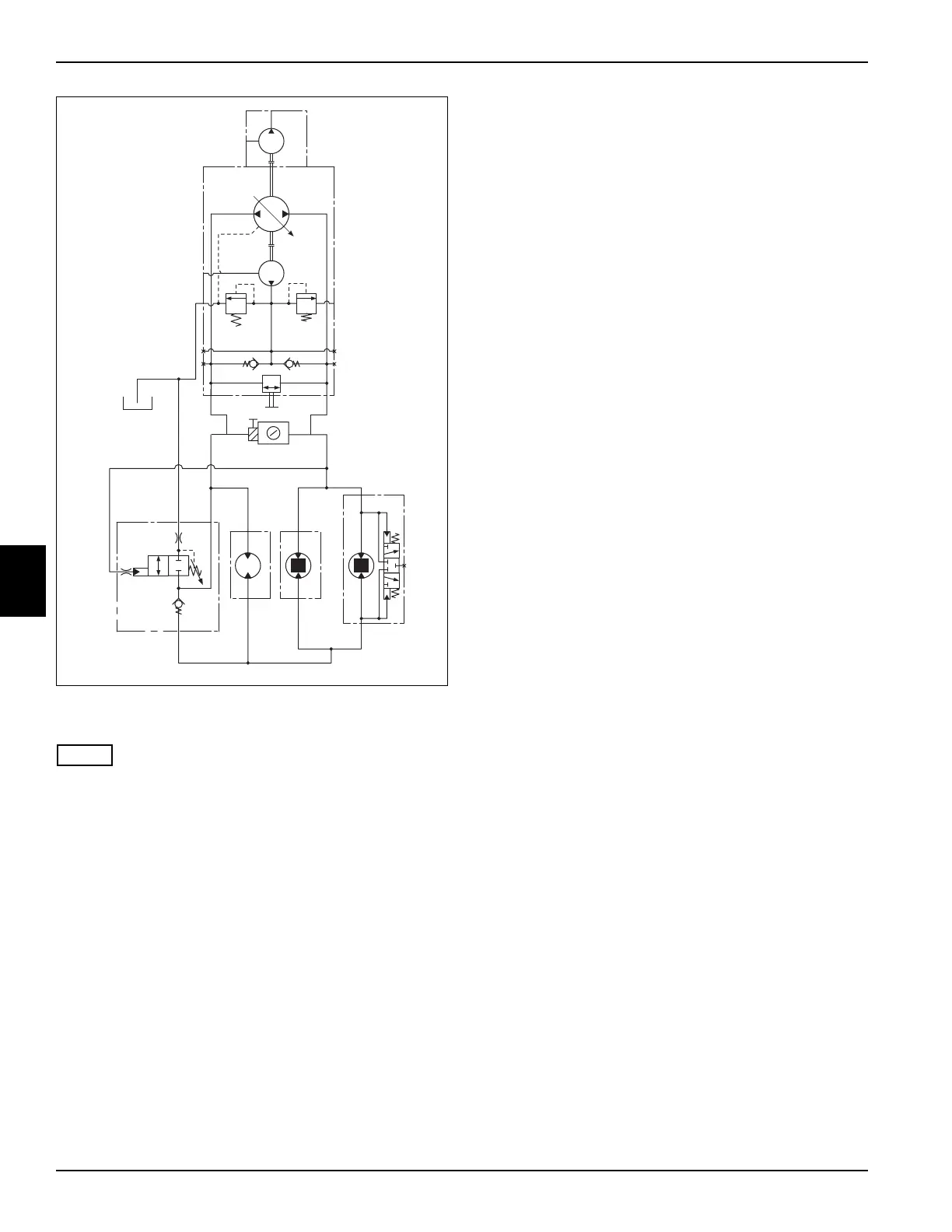

Figure 5-31: Traction System Test—3WD Models

—Front Wheel Motors Restrained

NOTE

Verify engine rpm is within specification (3400 rpm ± 50)

to ensure accurate hydraulic test results.

24. Start engine, release park brake, and run at full

throttle (3400 rpm ± 50).

25. Adjust flow lock tool (2) to allow pump to produce 7

gpm (27 lpm) in the forward direction.

26. Use the flow meter to warm the hydraulic oil. Turn

flow meter valve until a reading of 1000 psi (69 bar)

is reached. Warm the oil to 120–150° F (49–65° C);

open valve fully after operating temperature is

reached.

27. After warming the hydraulic oil, verify flow lock tool is

adjusted to allow pump to produce 7 gpm (27 lpm) in

the forward direction. Read and record no load flow.

28. Slowly close flow meter valve until a reading of

2500 psi (172 bar) is reached. Read and record

loaded flow.

29. Stop engine, apply park brake, and return flow lock

tool to the neutral position.

30. Calculate traction system leakage.

(Step 27 – Step 28 / Step 27 x 100 = Leakage

Percentage)

Is traction system leakage 10% or less?

YES The traction system is good. Additional

testing is required. Proceed to “Wheel

Motors Tests” on page 5-43.

NO Proceed to next question.

Is traction system leakage 11–20%?

YES The traction system is marginal. Additional

testing is required. Proceed to “Traction

Pump Tests” on page 5-41.

NO Proceed to next question.

Is traction system leakage 21% or more?

YES Test individual components in traction

system for leakage. Proceed to “Traction

Pump Tests” on page 5-41.

TN3103

Loading...

Loading...