CFM-BL10Pro General instruction manual

79 / 87

8. Trouble shooting

If you have any trouble, please refer to the below.

8.1. CFM cannot detect critical defective samples.

Critical defective samples such as no strands crimp, no strip crimp, double terminal

crimp and so on must be detected byCFM-BL10Pro. CFM is designed to detect those

defective samples even with the roughest tolerance, Tol No.8. If it cannot detect

them, CFM might not be cable to accurately capture force curves. The possible

causes are below.

Cause 1 : Sensor installation is not accurate and the sensor sensitivity deteriorate.

Check if PSS sensor is correctly installed. And if base plate type sensor FTW is used,

check if the preload is correctly done.

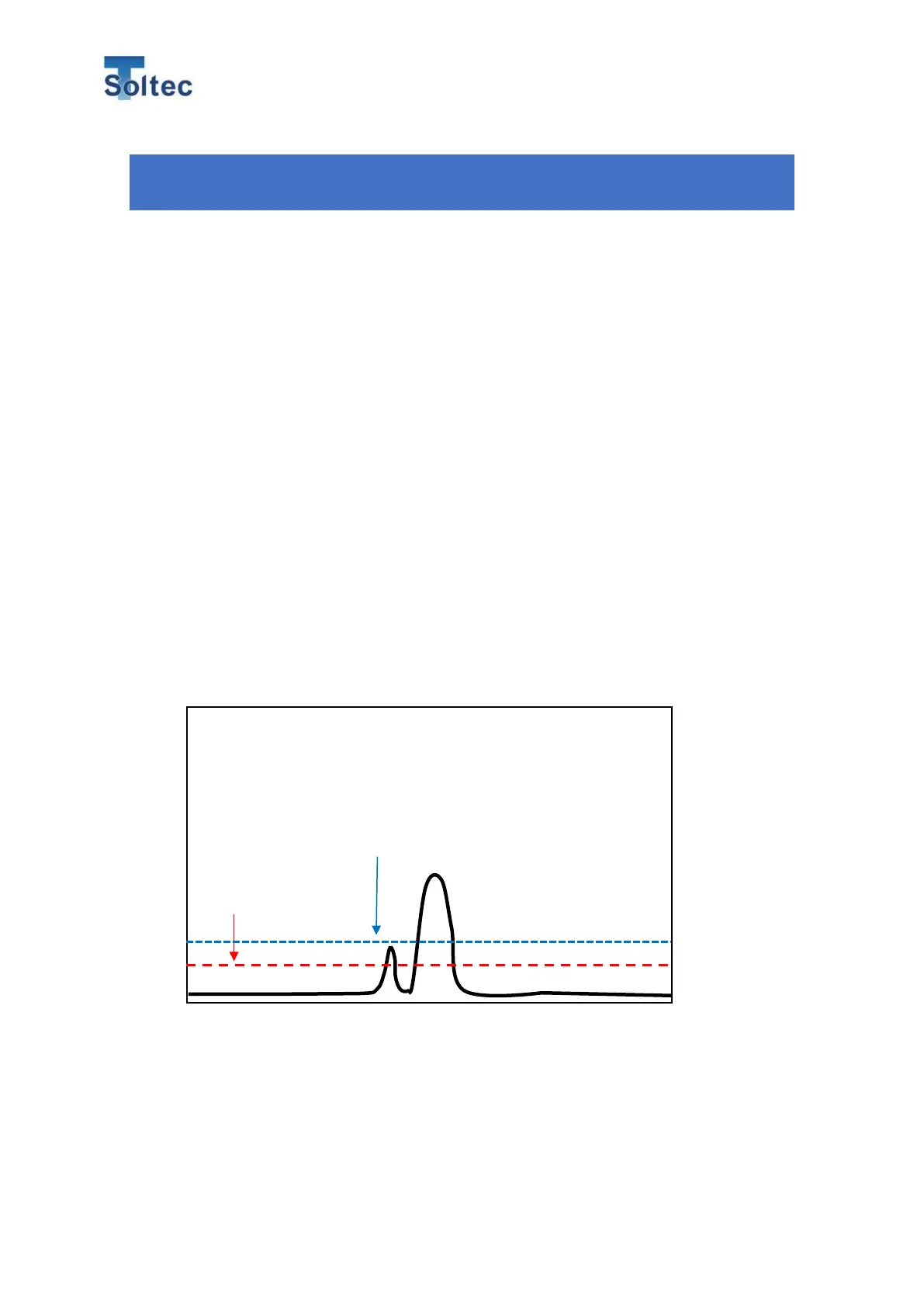

Cause 2 : Timing of Auto trigger force curve capturing is not correct and CFM does

not recognize an original force curve of crimping. Depending on the setting, CFM

might wrongly recognize machine noise appeared in front of an original crimping

force curve.

Because trigger level is too low, CFM wrongly captures machine noise appeared in

front of an original force curve. If the interval between machine noise and original

force curve is more than10ms, CFM might recognize the first output: machine noise

as the original force curve. Adjust the trigger level to a proper position.

Loading...

Loading...