CFM-BL10Pro General instruction manual

80 / 87

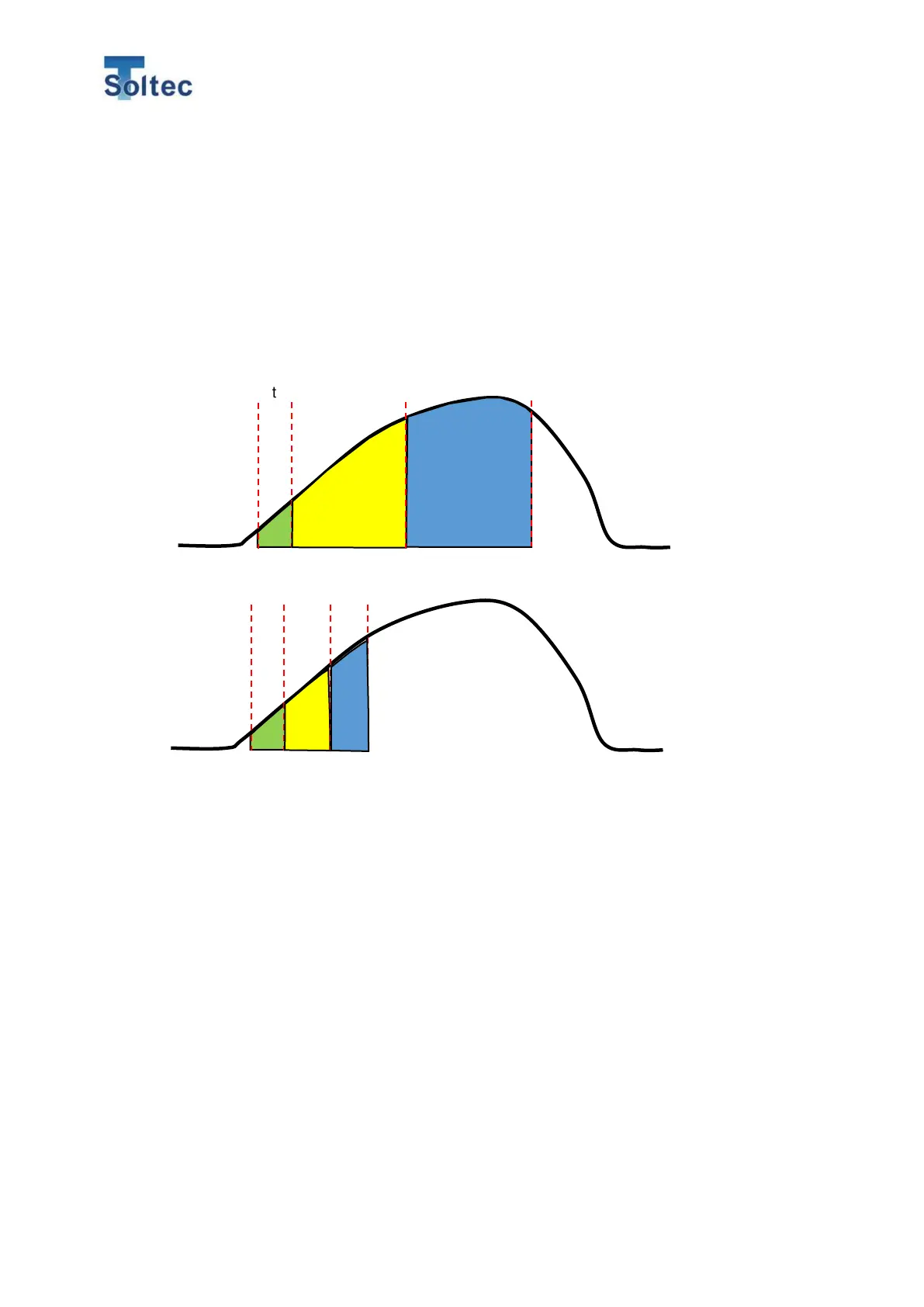

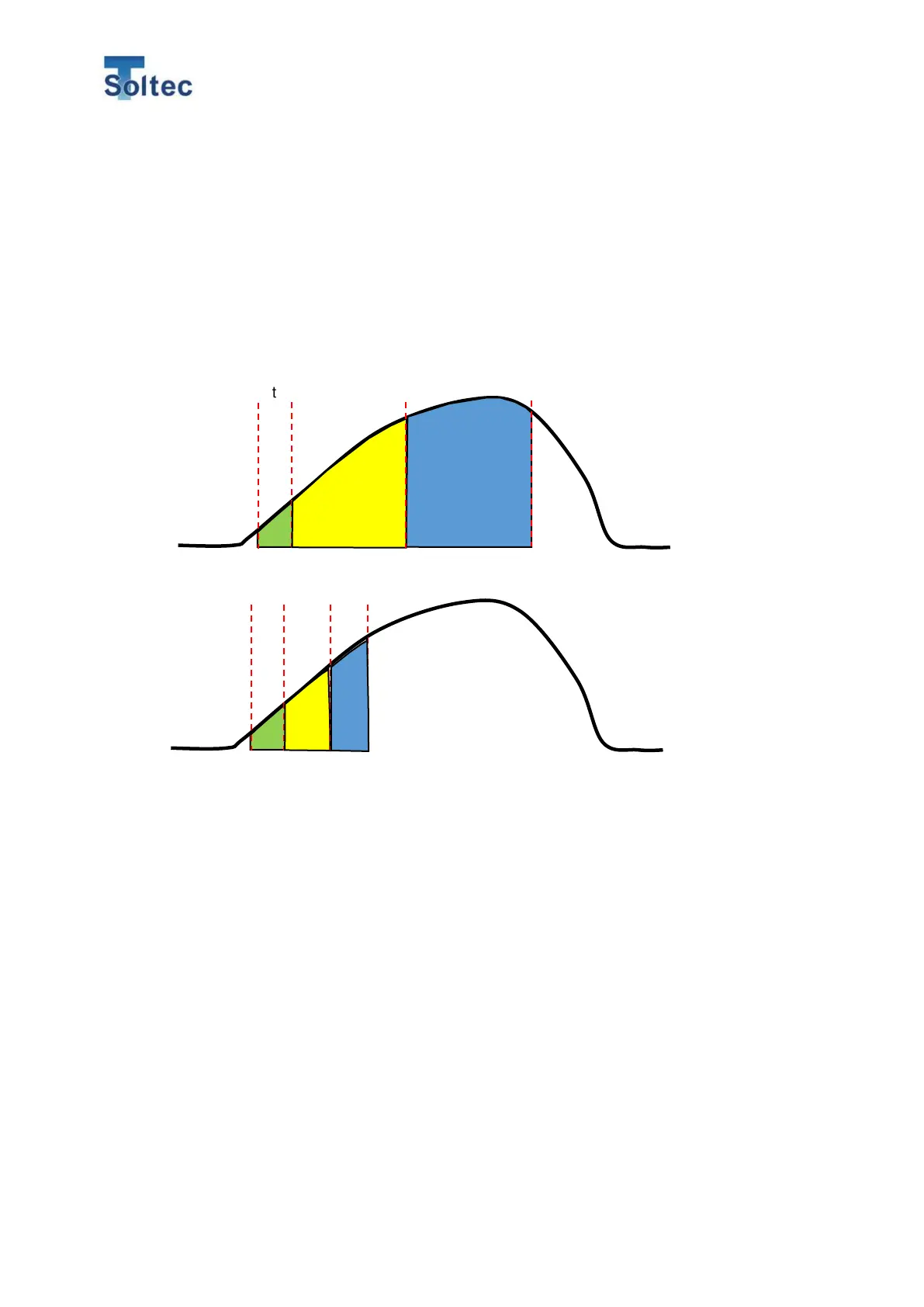

Cause 3 : Area divisions of the T1/T2/T3 are not correct and CFM cannot recognize

differences between good and bad samples.

As you can see the figure below, if the judgement area division is not correct, CFM

cannot detect defective samples.

The initial division lines are T1 Start:5%, T2 Start:30%, T3 Start:70% and T3 End:

90%. Please refer to 5.2.1 Program edit screen for the details of the Area.

If you cannot improve the accuracy of CFM judgement, revise the tolerance setting

as well.

8.2. CFM cannot detect subtle defective samples.

Detection of one strand cut and very subtle insulation crimp is affected by

combinations of terminals and wires, press machine or applicator conditions. With a

severe tolerance, CFM detects many kinds of defective samples, but many false

judgements occur. Crimp the defective samples which you want to detect and find the

tolerance that CFM can detect the defective samples with. Then check if the false

judgements occurred with the tolerance are acceptable.

T2 Start

T3 Start

T2

T2

Loading...

Loading...