CFM-BL10Pro General instruction manual

70 / 87

7. Installation and Maintenance

7.1. Sensor Installation

7.1.1. PSS sensor

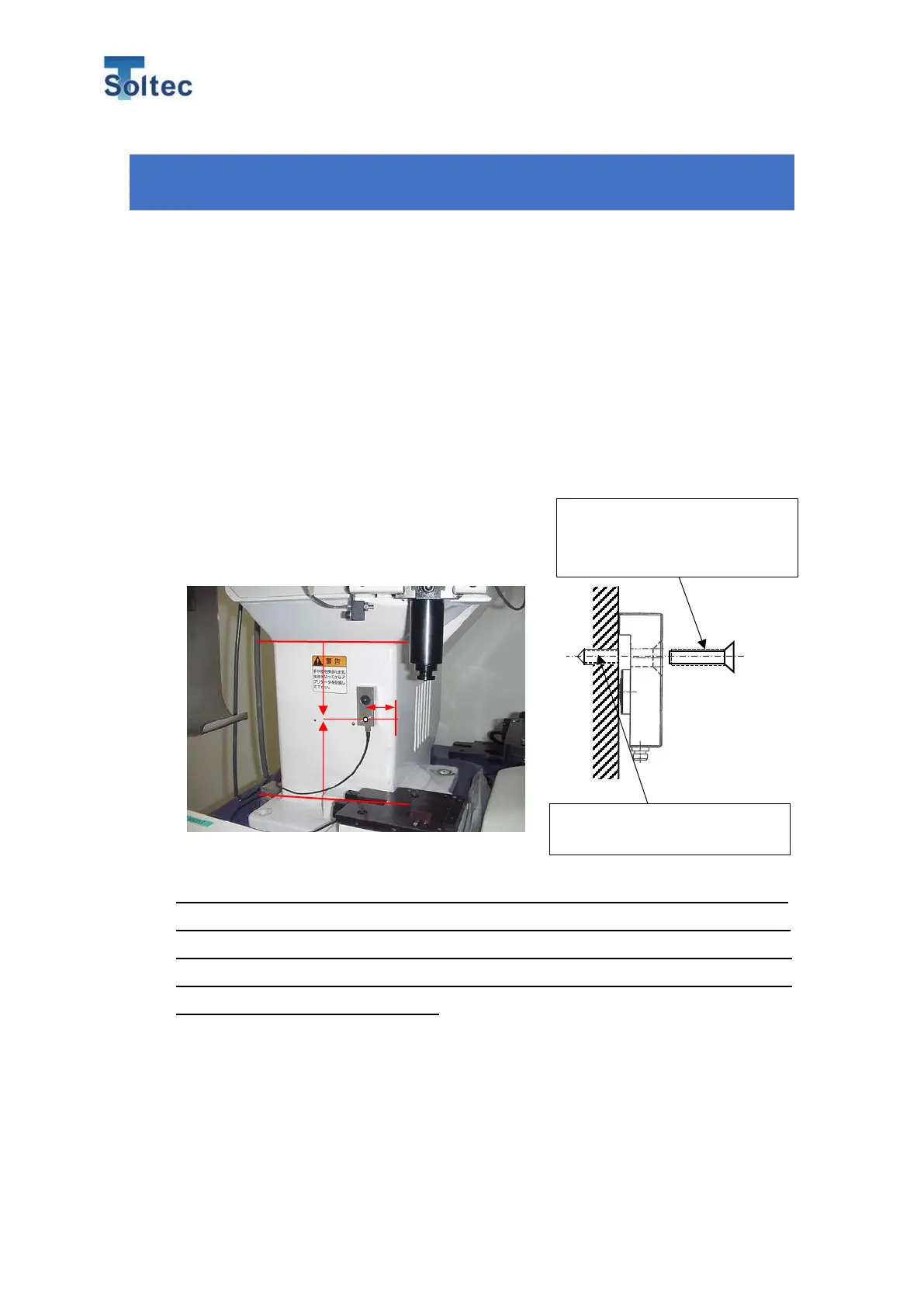

The correct setup position depends on the machine design. Basically, the sensor

should be installed the center of machine ram and base plate where machine has

the biggest elongation. For example, install the sensor behind applicator, vertically

at the center of the ram and base plate and horizontally near the ram on flat

surface.

If it cannot be installed in front of column because of applicator, install it where it

does not touch or hit applicator or something. It doesn’t matter whether the direction

of its cable is up or down.

In many cases, C-frame crimping machine has the biggest-elongation area is behind

the applicator (front side). Install the sensor vertically at the center of the column and

horizontally near ram. Normally no need to peel the paint of body surface, however, if

more sensitivity is needed like standard PSS50 can get so small force curve, you can

peel the paint to get more sensitivity.

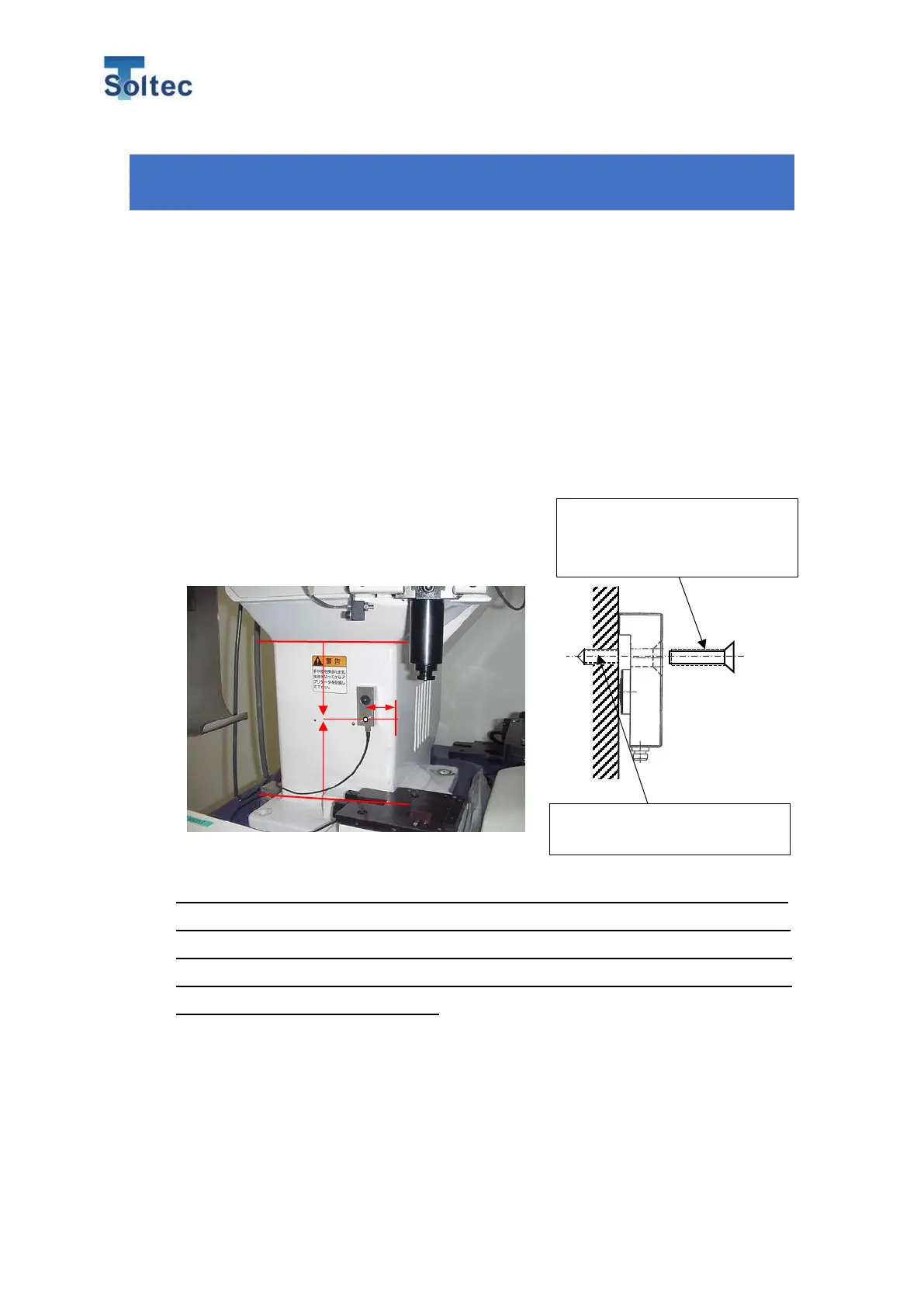

<Tightening torque>

The tightening torque is 7N・m(70kgf・cm)~10N・m(100kgF・cm).

Attached screw:

M6×1.0, length 22mm, and

countersunk head screw

Screw hole

M6×1.0, depth more than 12mm

Loading...

Loading...