CFM-BL10Pro General instruction manual

83 / 87

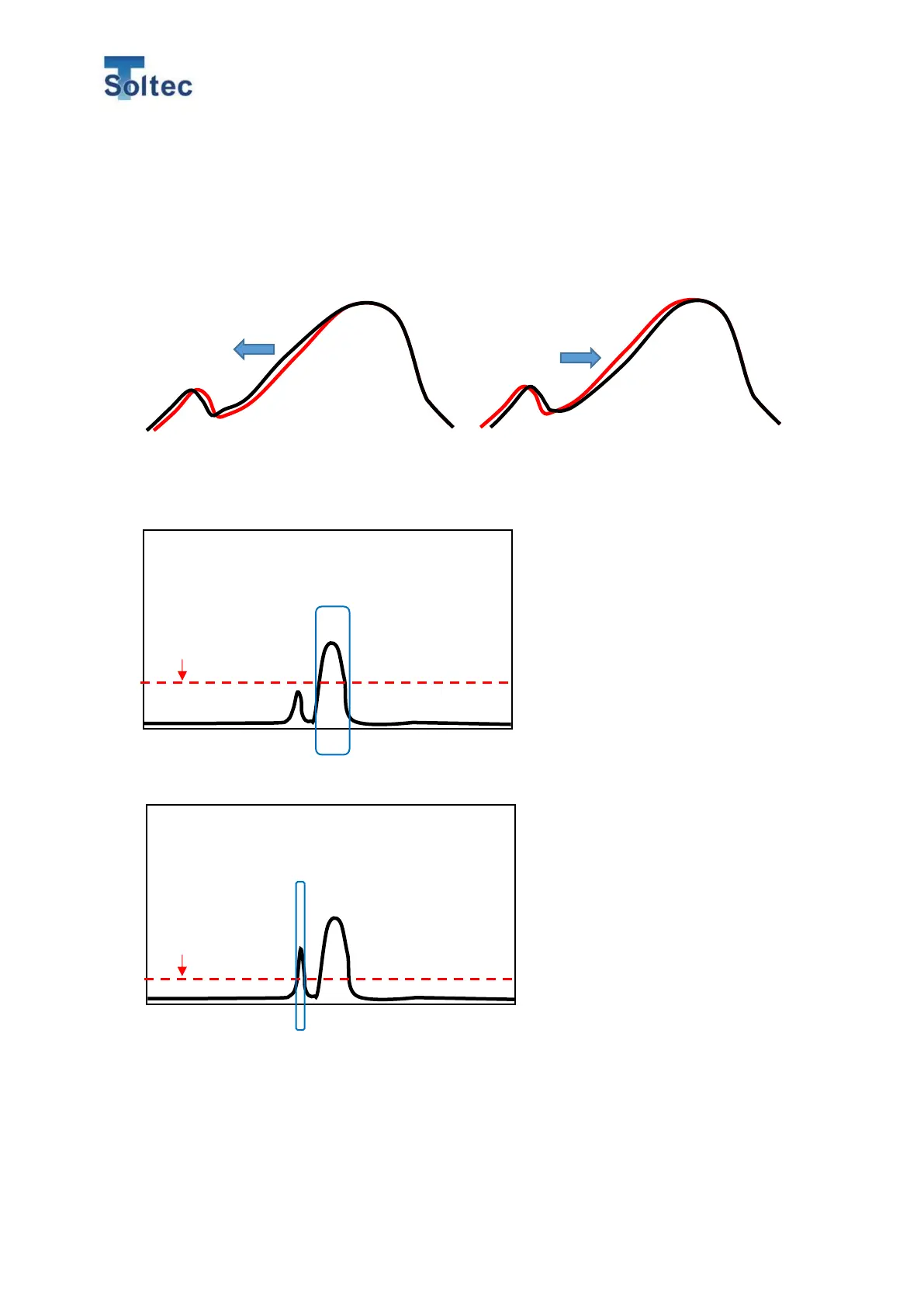

the actual curve does not match with the reference one. When the curves are not

aligned correctly with each other, it is difficult for CFM to compare those 2 curves and

make a precise judgement. Therefore, it is suggested to set the Alignment to 40% on

the right. In case of using servo crimping machines, you should set at 70% on the

left. Refer to 5.2.1 Program edit screen for how to set the alignment function.

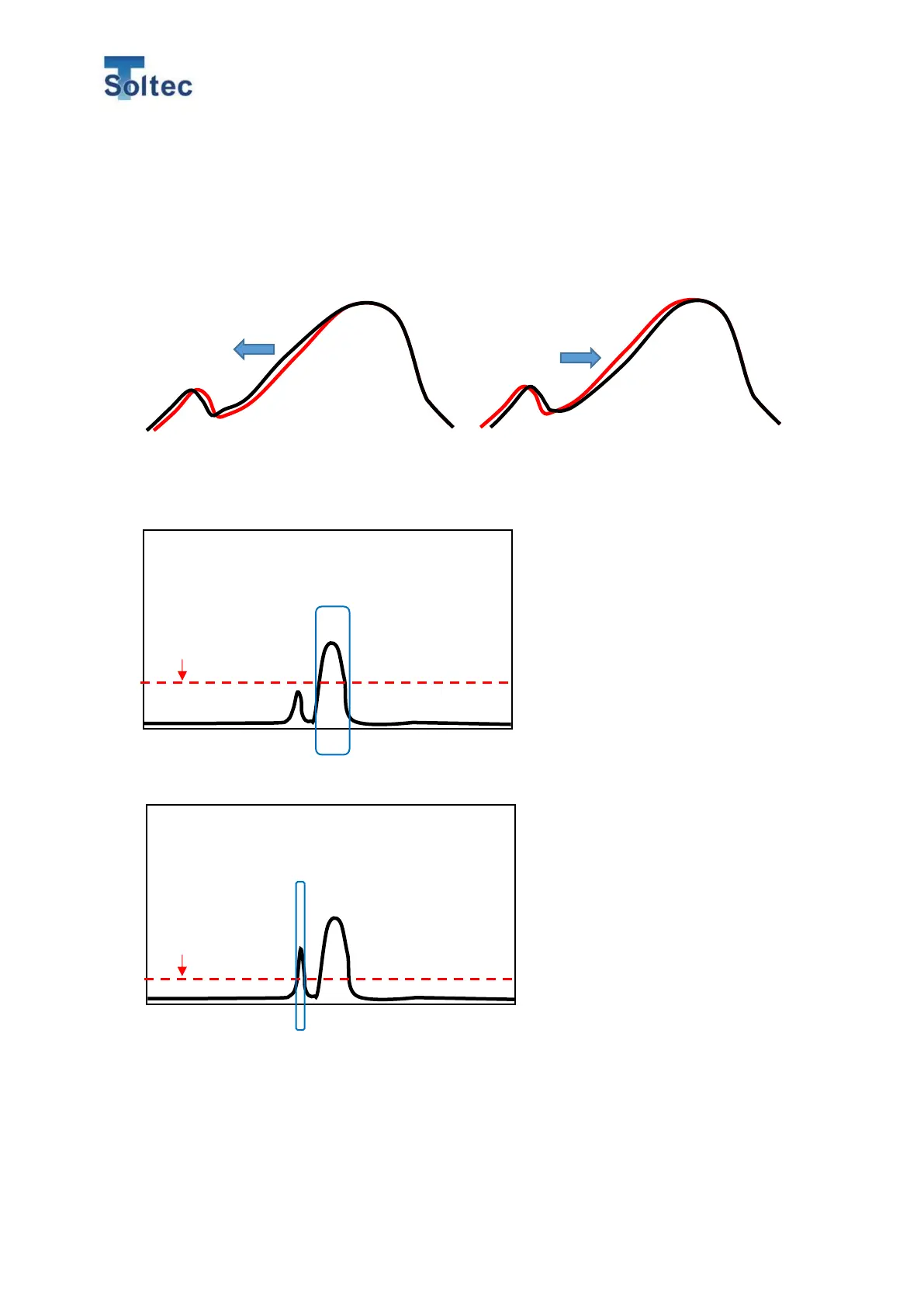

Cause 5: The waveform is unstable and different each time crimping. This causes

CFM to acknowledge the wrong curve, thereby making false alarms.

After doing TEACH, even if you use the same applicator, terminal, and wire, the noise

may still get in before or after the actual force curve depending on the conditions of

the crimping machines or applicators. This could attribute to mechanical or electrical

This graph shows the left half

of the wave either shifts to the

left / right

CFM acknowledges this

curve as an actual one.

CFM acknowledges this

curve as an actual one.

CFM detects 2 different force curves,

in which the 1

st

one may be from the

mechanical noise. Since the 1

st

one is

below the trigger level, CFM only

takes the 2

nd

curve for inspection.

In this case, the mechanical noise (1

st

curve) exceeds the trigger level, CFM

wrongly recognizes it as a force

curve.

Loading...

Loading...