HP10E / HP12E / HP15E / HP20E - Dairy design 6. Graphical control

6-65© VEMAG 2013

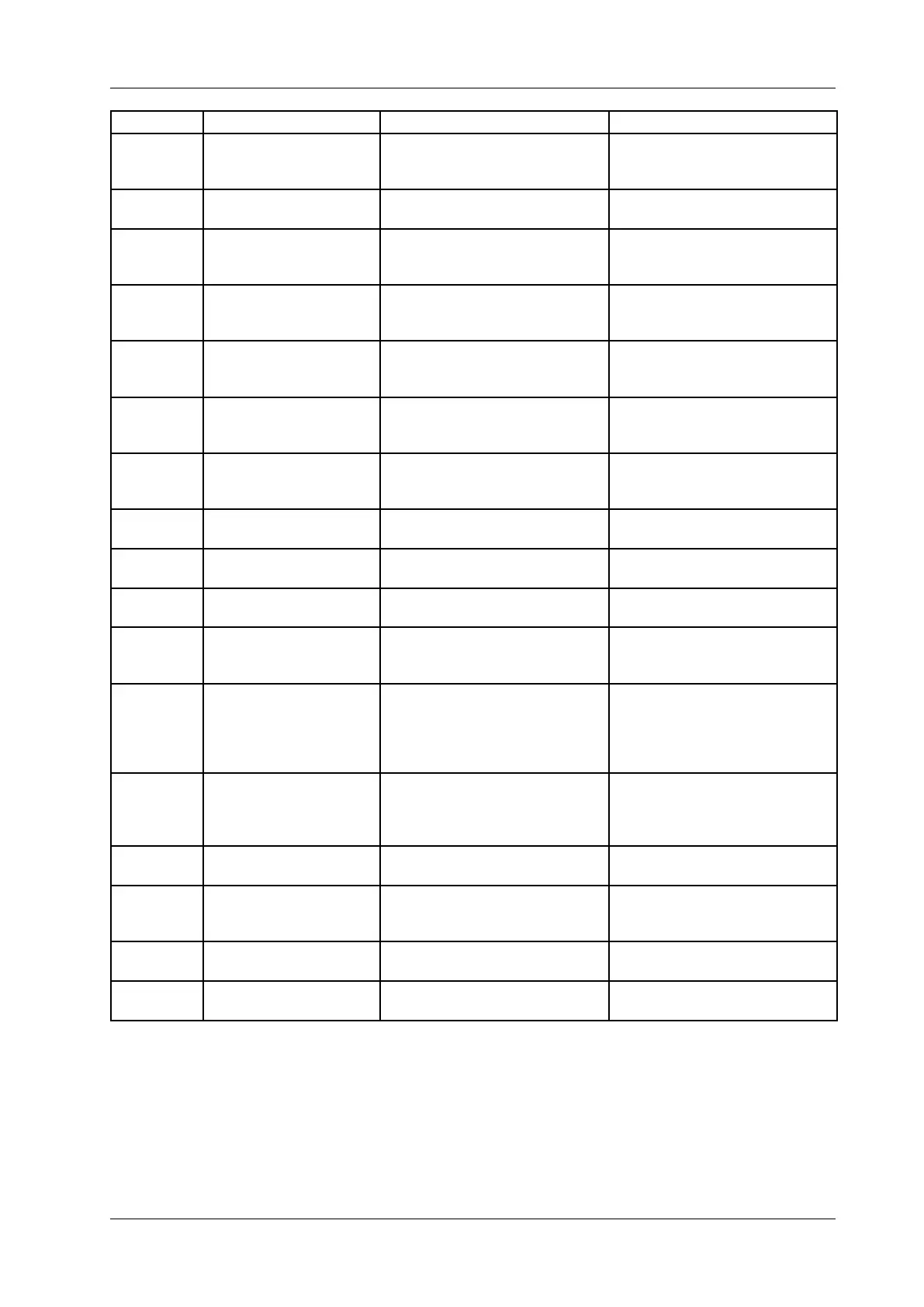

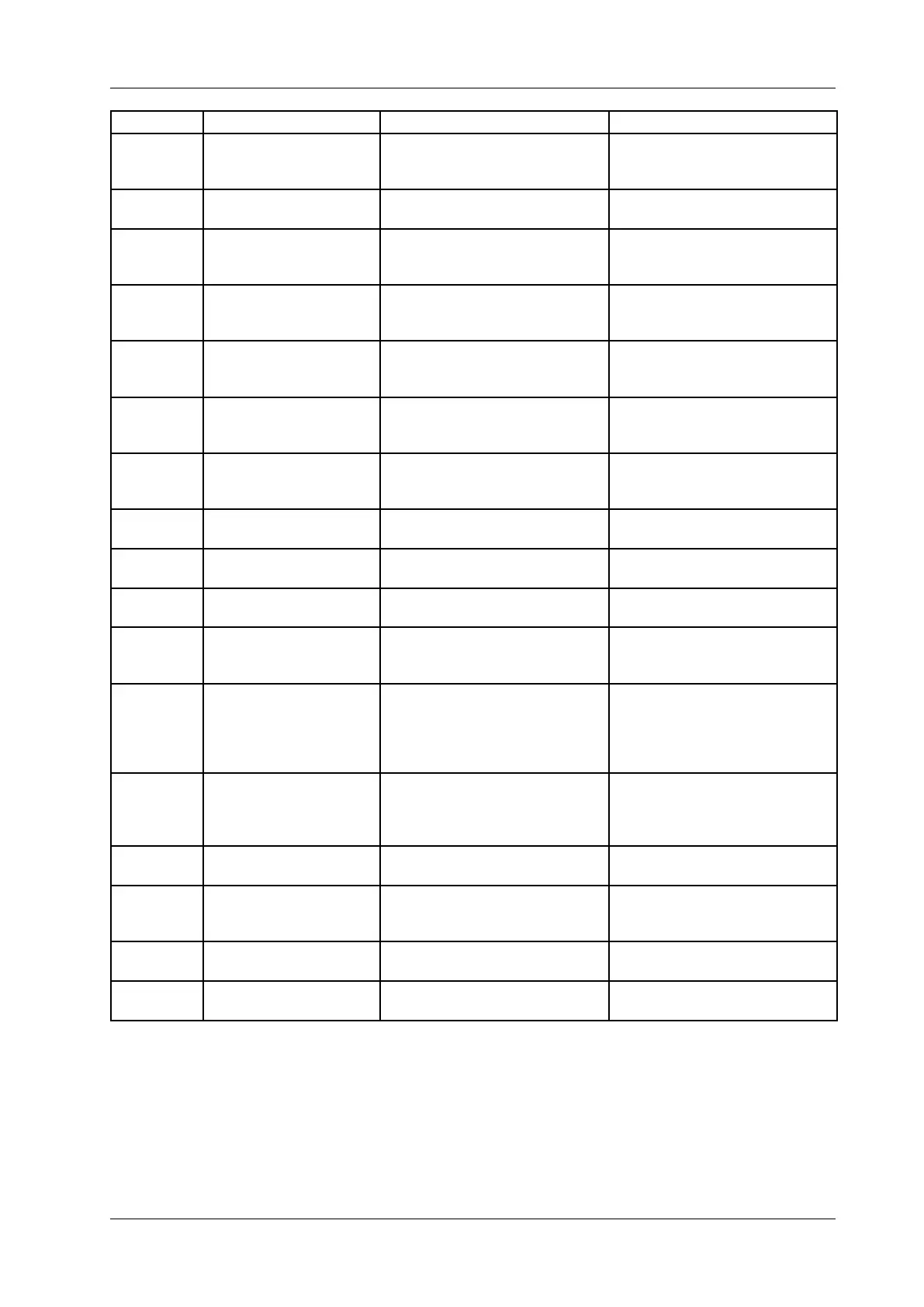

Number Message Cause Remedy

364 IO module A6 IO module A6 is not present or not

functioning properly.

Check that module A6 is rmly

seated; replace the module if

necessary.

365 Lubrication lling level The lubrication lling level is too

low.

Check the lubrication lling level.

366 Hoist not available There is a button signal for the

hoist even though a hoist has not

been set up.

Set up the hoist at service screen

2, if available. Check the wiring

and connection (terminal).

367 Hopper level = automati-

cally blocks hoist

If „Automatic“ is selected for the

„hopper level“ option, the hoist

buttons are inactive.

Select another mode for the hop-

per level if you want to activate the

hoist.

368 Hopper vacuum Vacuum hopper 149: the vacuum

in the hopper prevents the cover

from opening.

Select „Off“ for hopper mode.

400 Filling pressure too high! Filling pressure control has

stopped the machine.

In the case of grinding applications,

this may indicate blocked hole plates;

clean the hole plate if necessary.

401 Hopper empty? The hopper level sensor has

detected that the level has fallen

below the minimum value.

Pour product into the hopper.

402 System being lled! At the start of pressure control,

the pipe system is lled slowly.

-

403 Product temperature Product temperature outside set

range.

Reduce or increase product tem-

perature.

404 Tighten up union nut! Pressure monitoring: This hint ap-

pears after the pipe system is lled.

-

406 Stops due to product

temperature

A preset product volume was lled

in excess of the permitted tempe-

rature range.

Make sure that the product in the

hopper is at the right temperature.

Check the setup.

407 Minimum pressure not

achieved

(+ hopper empty?)

The machine could not attain 0.6

bar in the rst 15 seconds.

Check the sensor (function + po-

sition), ll the hopper, start it again

until the pipe is lled or deactivate

„Max. lling pressure“ if the sensor

is not needed.

408 Fallen below the minimum

pressure

(+ hopper empty?)

The pressure drops below 0.6 bar

for more than 5 seconds.

Check the sensor (function + posi-

tion), ll the hopper or deactivate

the „Max. lling pressure“ if the

sensor is not needed.

409 Max. speed timeout

(+ hopper empty?)

The machine could not attain the

pressure at full speed.

Check the sensor (function + posi-

tion) and ll the hopper.

410 Fallen below the minimum

vacuum

(+ hopper empty?)

The vacuum sensor has deter-

mined that the vacuum is below

the minimum.

Fill the hopper and check the

sensor.

420 More samples! Scale 877 The operator is requested

to put another sample on the scale.

-

421 Result printing! Scale 877 The scale report

is printing.

-

Loading...

Loading...