HP10E / HP12E / HP15E / HP20E - Dairy design6. Graphical control

6-70 © VEMAG 2013

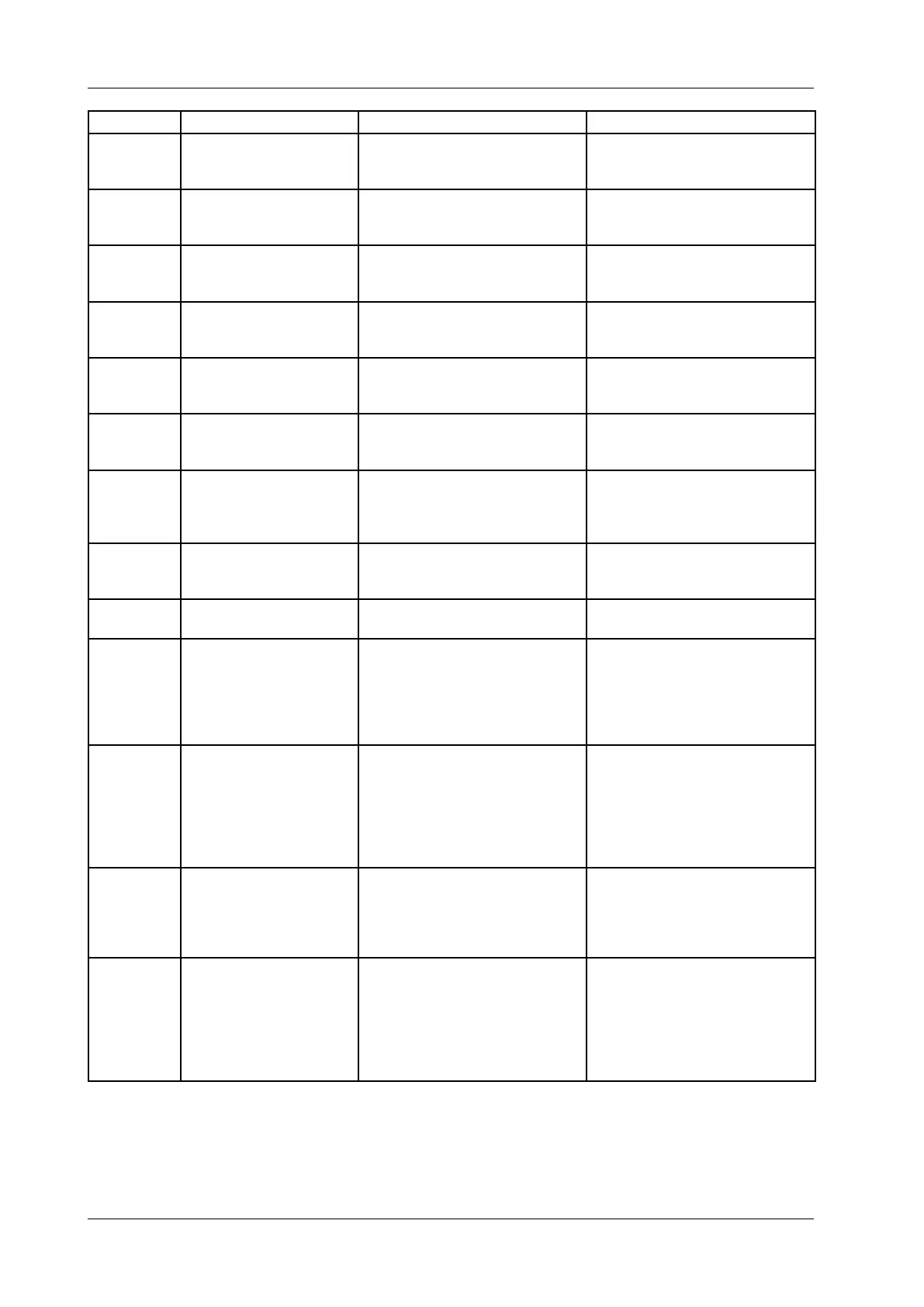

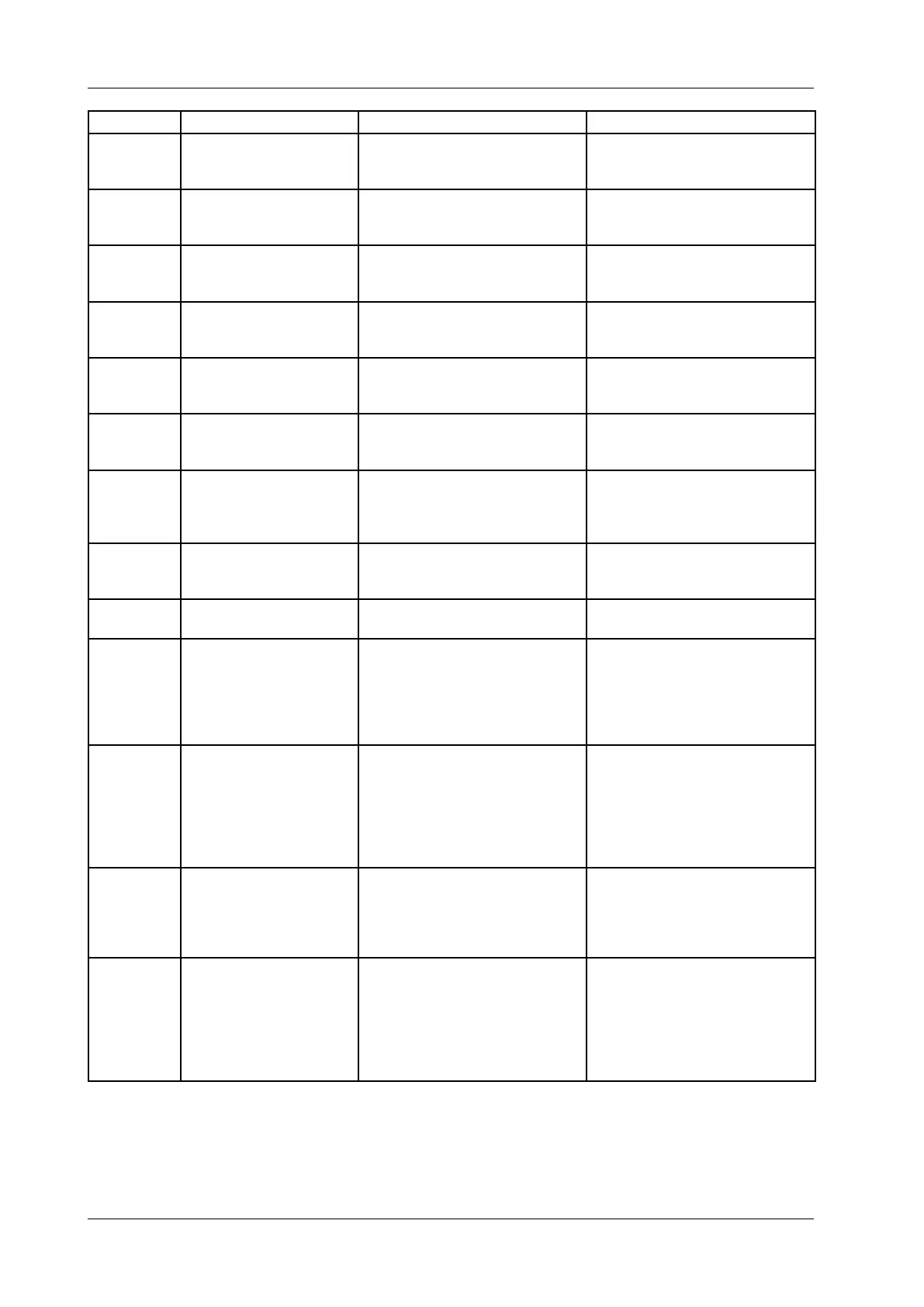

Number Message Cause Remedy

813 Weight/speed limits knife

offset

The value range for input depends

on another parameter and vice

versa.

-

814 input limit reached The value range for input depends

on another parameter and vice

versa.

-

815 Weight/speed limits knife

time

The value range for input depends

on another parameter and vice

versa.

-

816 Weight/knife time limits

speed

The value range for input depends

on another parameter and vice

versa.

-

817 Belt speed too high! The value range for input depends

on another parameter and vice

versa.

-

818 Coextrusion delay too

long!

The value range for input depends

on another parameter and vice

versa.

-

819 Weight limits speed The combination of weight, feed

system, portions per signals and

external signals requires a speed

> 100 %.

Modify settings, check signals

at S-K.

820 Input limit reached The length of the empty casing

is limited to guarantee reliable

conveying.

-

821 Speed limit reached Filling (or belt) speed was limited

by the specied value.

Accept the speed limit or increase

the specied value.

822 Print mark control active With the print mark control feature,

the lling volume is controlled

using print marks on the casing

(with signals to Remote-K). This

message appears when you enter

a weight correction in this mode.

Conrm whether the print marks

on the casing or a preset weight

correction should be used to

control the output weight. Activate

or deactivate the print mark control

application.

823 Poor distance For the print mark control applica-

tion, it is important that the print

mark signal (Remote-K) is given

while one portion is being lled.

Otherwise the message indicates

that the sensor is ill positioned

(distance to clipping area).

Position the sensor so that the

signal (Remote-K) is around the

centre of the portion.

827 Hanging speed exceeded AH 204: the current setting leads

to more than 300 hooks per

minute (= limit value). This value

can only be reached without empty

pins between the hooks.

Find a setting that leads to fewer

hooks per minute.

828 Portion frequency incre-

ased

AH 204: the time between two

hook signals has shortened. The

machine cannot implement this.

The sausage per hook value has

been doubled!

Check if there actually are pro-

blems during hanging. Ignore the

message if there are no pro-

blems. Otherwise, note all version

numbers and program settings

and notify VEMAG Customer

Service.

Loading...

Loading...