POWR

Power unit

5-63

62Y3A11

4. When installing the main bearing, insert

the projection of the main bearing into

the slot on the cylinder body.

CAUTION:

Remove any small metal particles and oil

from the contact surfaces of the cylinder

body and the main bearing.

5. Measure the main journal oil clearance

with a piece of Plastigauge (PG-1).

6. If the oil clearance is below specification,

check the main bearing color and clean

the contact surface of the cylinder body

and the main bearing, and then check

the main journal oil clearance again.

7. If the oil clearance is over specification,

install an oversized main bearing, and

then check the main journal oil clearance

again.

Selecting the connecting rod big end

bearing

1. When replacing the connecting rod bear-

ing, select the suitable connecting rod

bearing as follows.

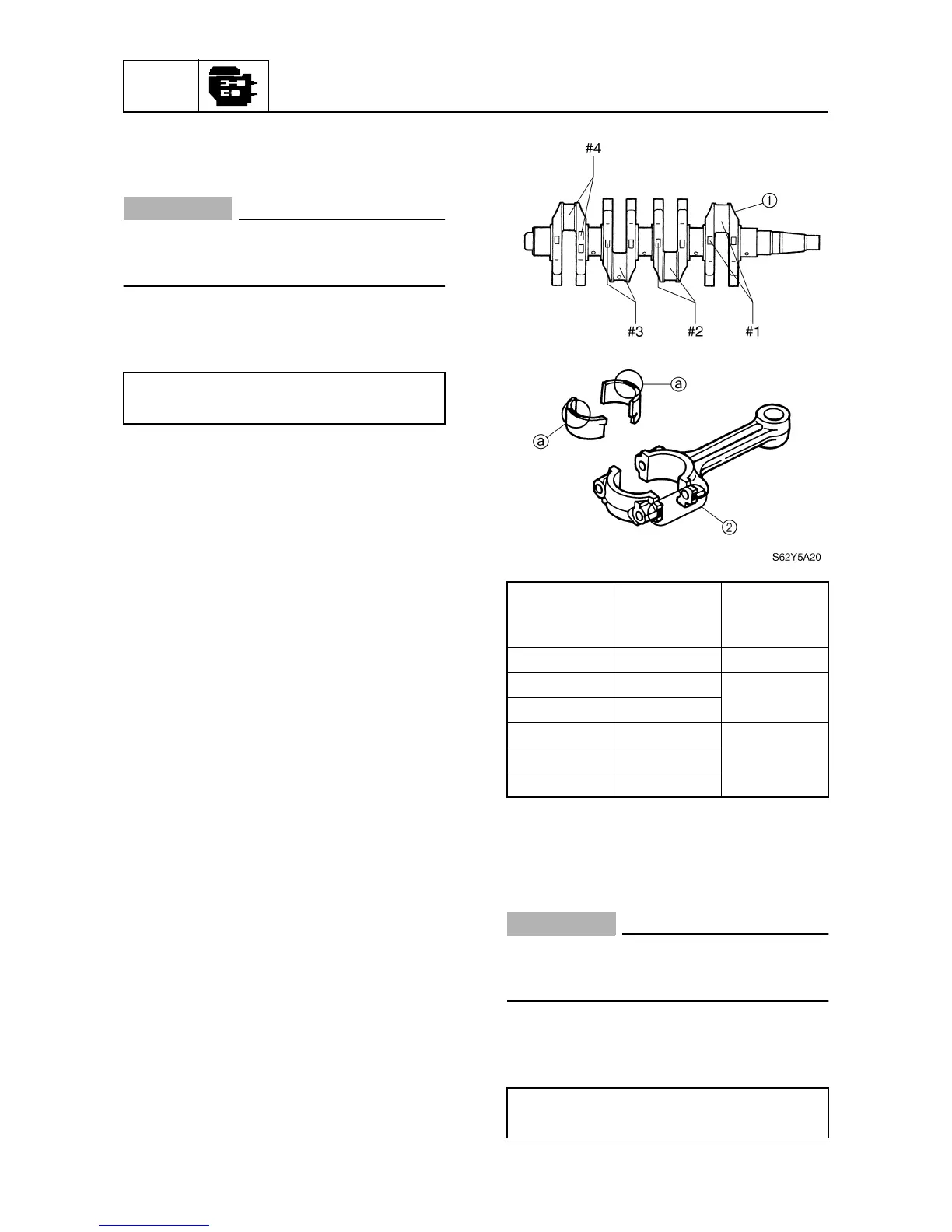

2. Check the crank pin mark on the crank-

shaft

1

and the connecting rod cap mark

or painted color on the connecting rod

2

.

3. Select the suitable color

a

for the con-

necting rod bearing from the table.

4. When installing the connecting rod bear-

ing, insert the projection of the connect-

ing rod bearing into the slot on the

connecting rod.

CAUTION:

Remove any small metal particles and oil

from the contact surfaces of the connect-

ing rod and the connecting rod bearing.

5. Measure the crank pin oil clearance with

a piece of Plastigauge (PG-1).

Crankshaft main journal oil clearance:

0.012–0.036 mm (0.0005–0.0014 in)

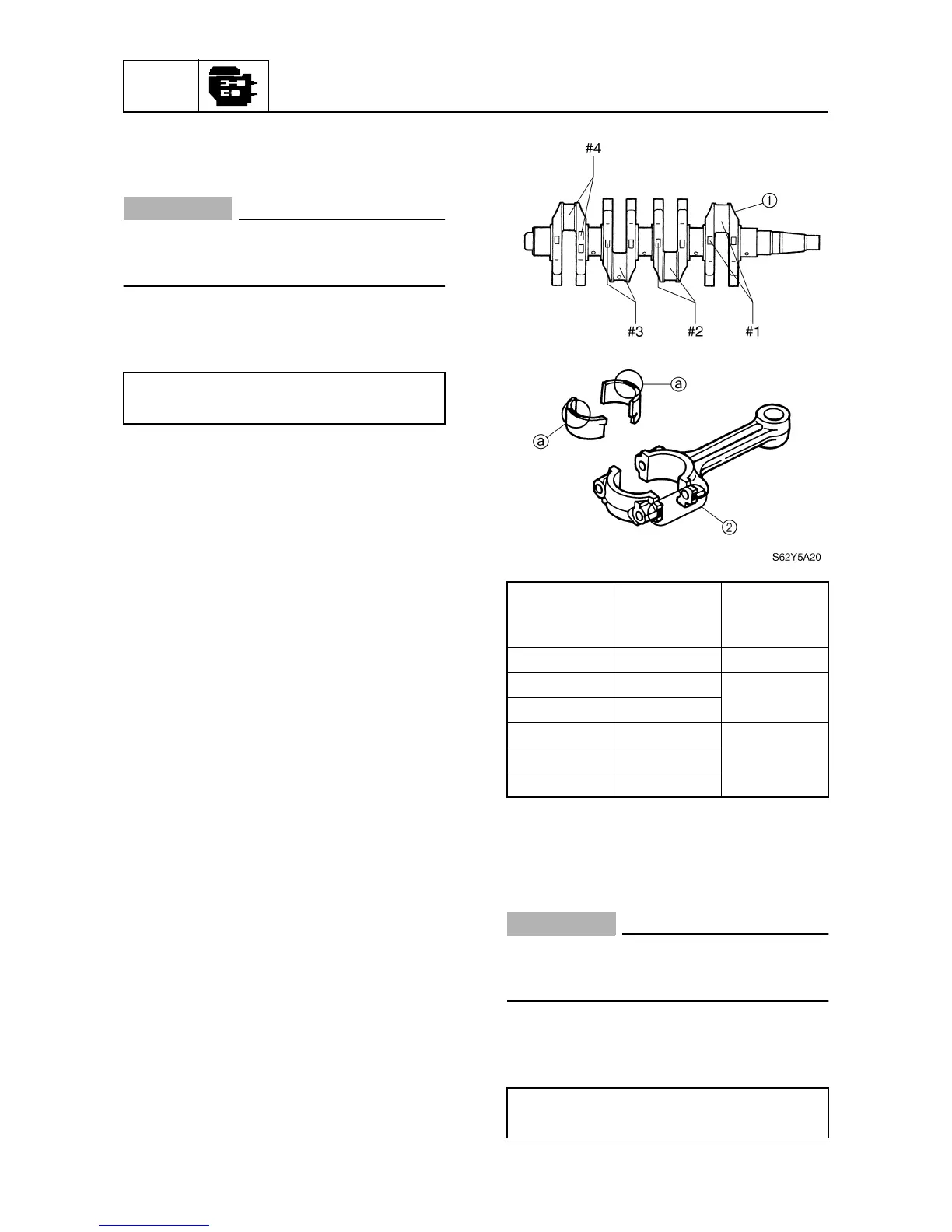

Connecting

rod cap

mark/color

Crank pin

mark

Bearing

color

I

/Red A Yellow

I

/Red B

Red

II

/Blue A

II

/Blue B

Pink

III

/Yellow A

III

/Yellow B Green

Crank pin oil clearance:

0.016–0.040 mm (0.0006–0.0015 in)

Loading...

Loading...