62Y3A11

6-32

1

2

3

4

5

6

7

8

I

Shimming

NOTE:

• Shimming is not required when assembling

the original lower case and inner parts.

• Shimming is required when assembling the

original inner parts and a new lower case.

• Shimming is required when replacing the

inner parts.

Selecting the pinion shims

1. Calculate the specified value (M0) as

shown in the examples below.

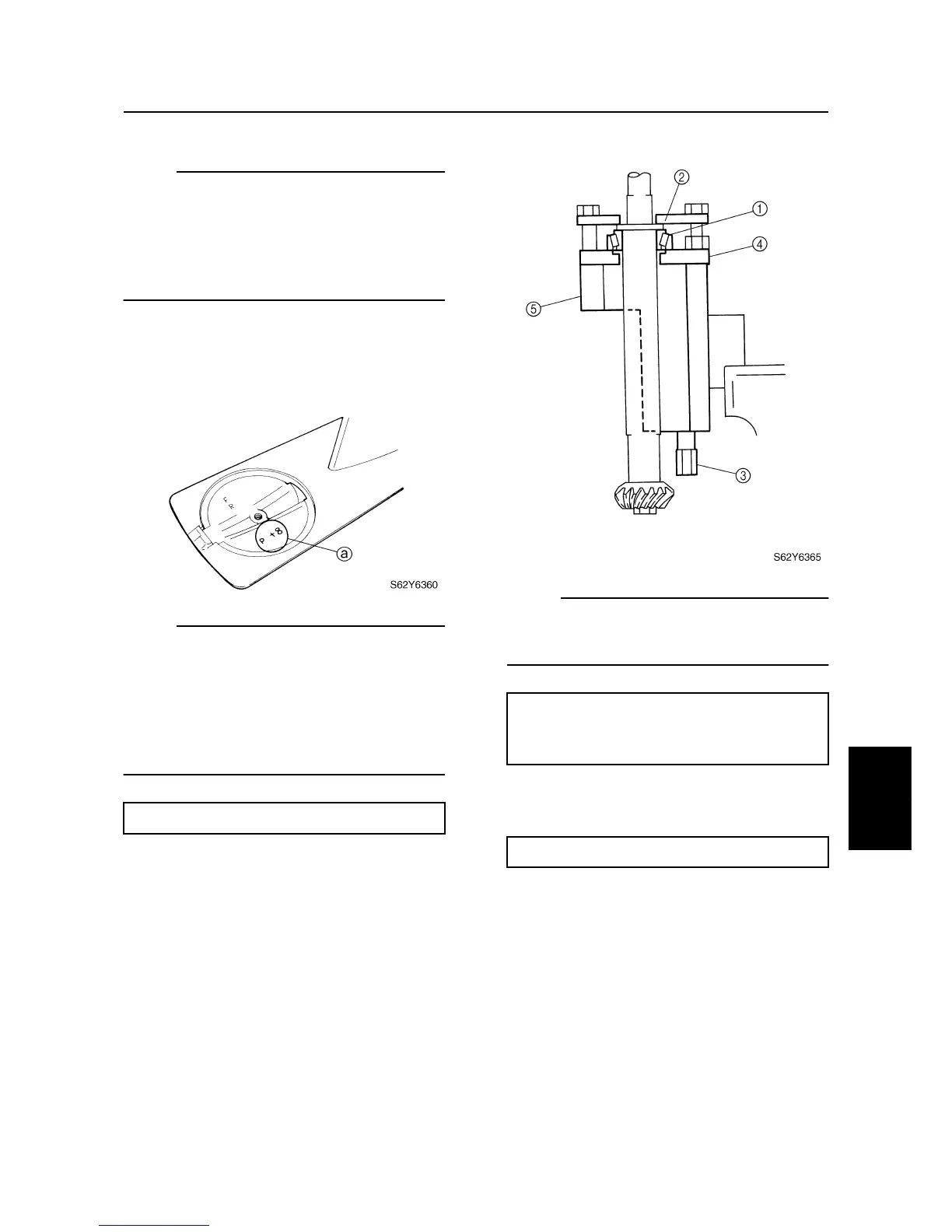

NOTE:

“P” is the deviation of the lower case dimen-

sion from standard. The “P” mark

a

is

stamped on the trim tab mounting surface of

the lower case in 0.01 mm units. If the “P”

mark is unreadable, assume that “P” is zero

and check the backlash when the unit is

assembled.

Example:

If “P” is “+5”, then

M0 = 0.30 + (+5)/100 mm = 0.30 + 0.05 mm

= 0.35 mm

If “P” is “–5”, then

M0 = 0.30 + (–5)/100 mm = 0.30 – 0.05 mm

= 0.25 mm

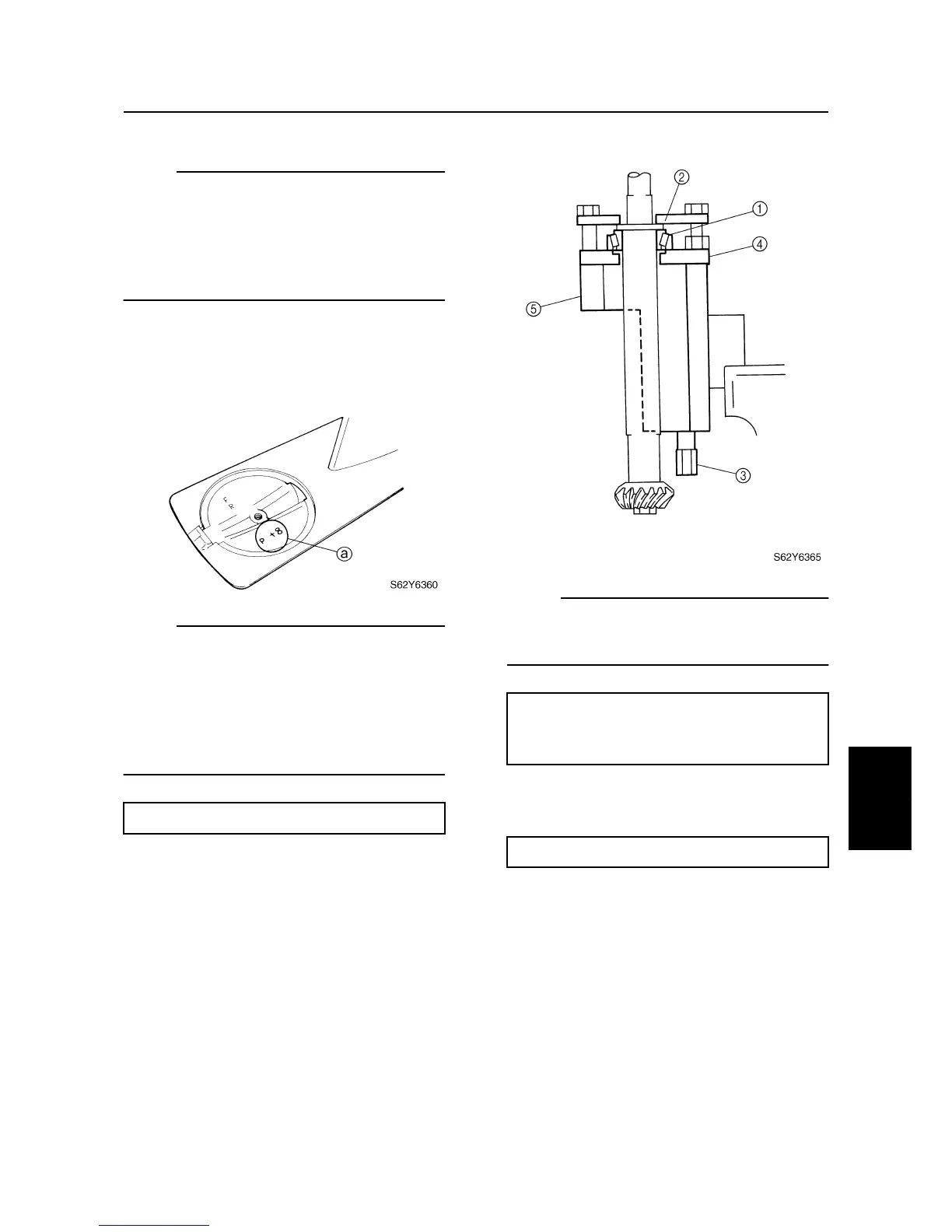

2. Install the drive shaft and drive shaft

bearing

1

to the shim selecting tools.

3. Attach the clamp

2

to the gauge base

using four bolts of appropriate sizes.

NOTE:

Install the shim selecting tools to the drive

shaft so that the shaft is at the center of the

hole.

4. Install the pinion and pinion nut, and then

tighten the nut to the specified torque.

Specified value (M0) = 0.30 + P/100 mm

Pinion shim selecting tools:

YB-34432-8

3

, YB-34432-10A

4

,

YB-34432-11A

5

, YB-34432-17

2

Pinion nut: 75 N·m (7.5 kgf·m, 54 ft·lb)

Shimming (F50) (for USA and Canada)

Loading...

Loading...