ELEC

Electrical systems

– +

8-17

62Y3A11

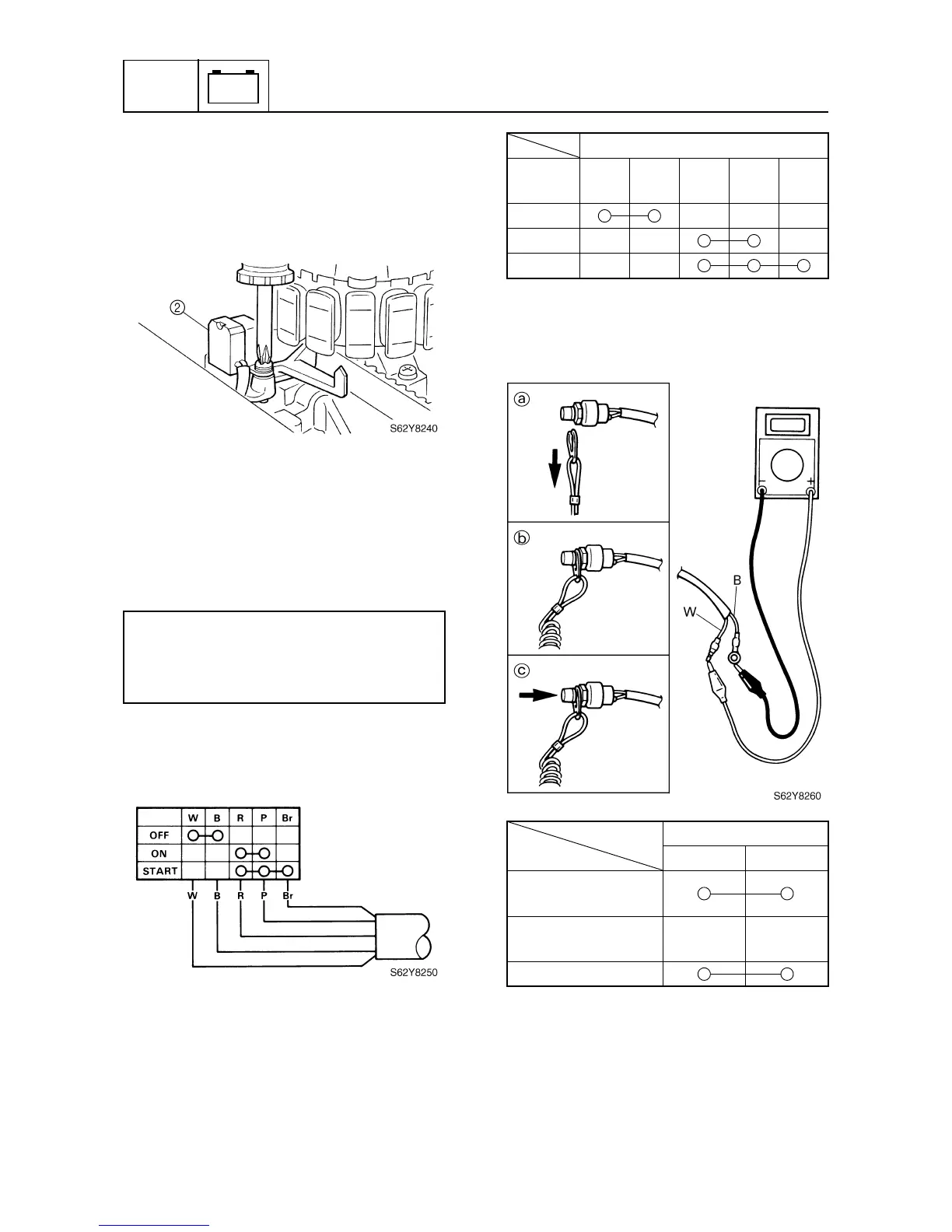

3. Remove the flywheel magnet nut and fly-

wheel magnet.

4. Loosen the pulser coil screws, adjust the

pulser coil

2

position, and then tighten

the screws finger tight.

5. Set the flywheel magnet and then check

the gap again and, if necessary, repeat

steps 3–5.

6. Tighten the pulser coil screws and fly-

wheel magnet nut to the specified

torques.

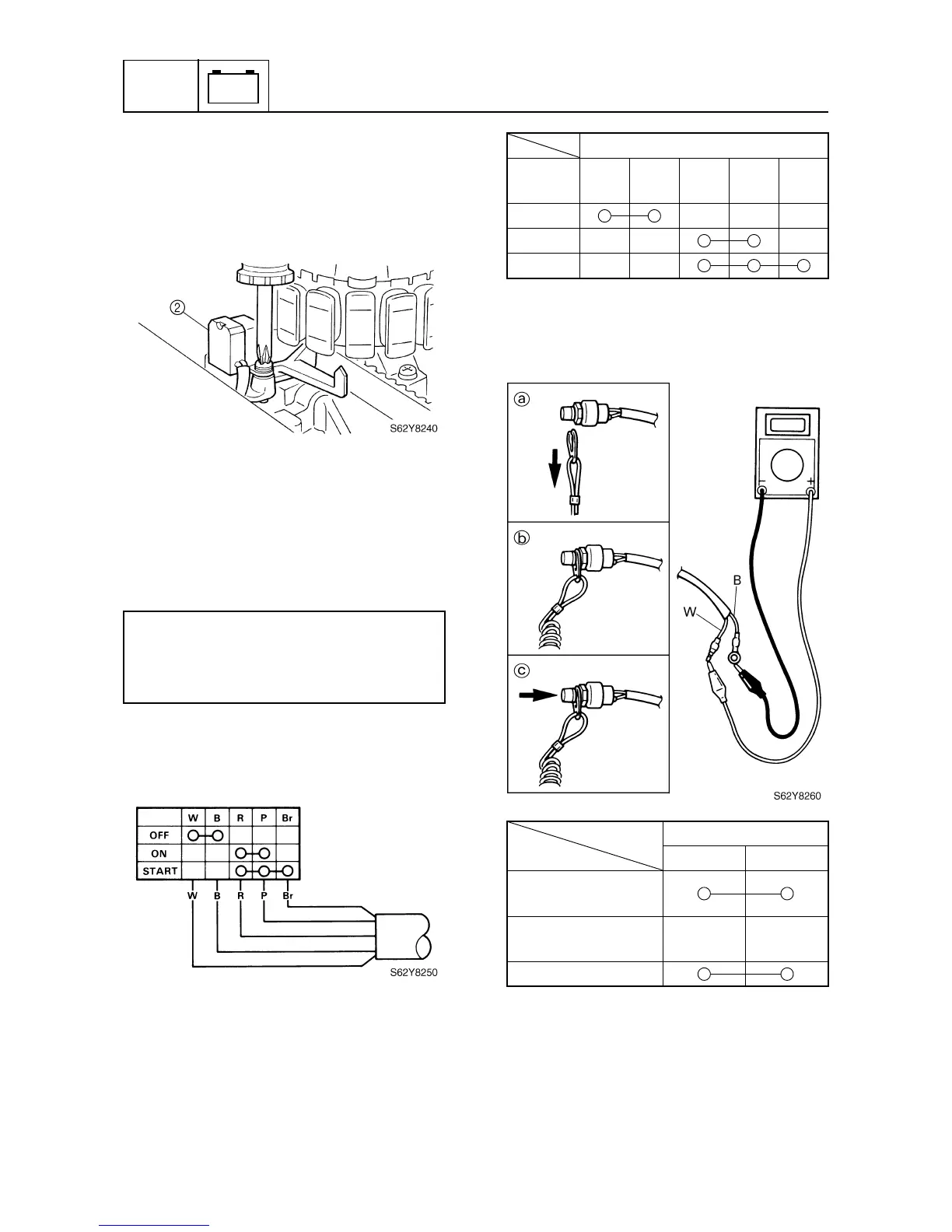

Checking the engine start switch

1. Check the engine start switch for continu-

ity. Replace if there is no continuity.

Checking the engine shut-off switch

1. Check the engine shut-off switch for con-

tinuity. Replace if there is no continuity.

Pulser coil screw:

4 N·m (0.4 kgf·m, 2.9 ft·lb)

Flywheel magnet nut:

160 N·m (16 kgf·m, 116 ft·lb)

Lead color

Switch

position

White

(W)

Black

(B)

Red

(R)

Pink

(P)

Brown

(Br)

OFF

ON

START

Lead color

White (W)

Black (B)

Remove the lock

plate

a

Install the lock

plate

b

Push the button

c

Loading...

Loading...