Chapter 6 Cooling Water System

4.

Heat

Exchanger

_______________________________

3,4JH3(B)(C)E

4-2

Specifications

of

heat exchanger

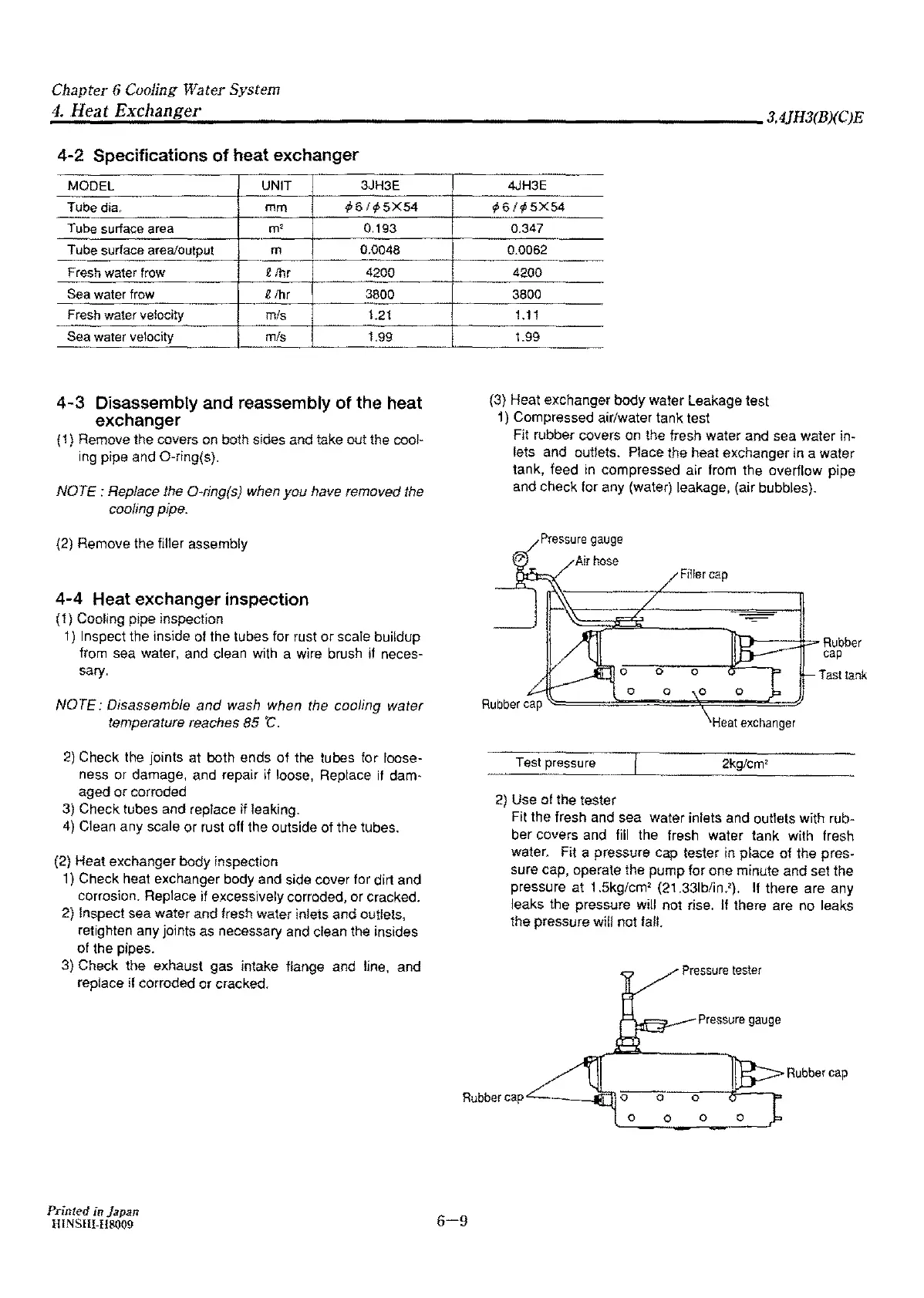

MODEL

UNIT

3JH3E

Tube dia.

mm

¢,

6 I tf

5X54

Tube

surface area

rn'

0.193

Tube surface area/output

m 0.0048

Fresh water frow

Uhr

4200

Sea water frow €/hr

3800

Fresh water velocity

mis

L21

Sea water velocity

m/s

1.99

4-3

Disassembly and reassembly of the heat

exchanger

{ 1 } Remove the covers on both sides and take out the cool-

ing pipe and O-ring{s}.

NOTE : Replace the 0-ring(s) when you have removed the

cooling pipe.

(2} Remove the filler assembly

4-4

Heat exchanger inspection

(1) Cooling pipe inspection

1)

Inspect the inside

of

the tubes for rust

or

scale buildup

from sea water, and clean with a wire brush

ii

neces-

sary.

NOTE:

Disassemble

and

wash when the cooling water

temperature reaches

85

t'.

2}

Check the joints at both ends of the tubes

for

loose-

ness or damage, and repair

if

loose, Replace ii dam-

aged

or

corroded

3)

Check tubes and replace

if

leaking.

4) Clean any scale or rust off the outside of the tubes.

(2) Heat exchanger

body

inspection

1)

Check heat exchanger body and side cover for dirt and

corrosion. Replace if excessively corroded, or cracked.

2) Inspect sea water and fresh water inlets and outlets,

retighten any joints as necessary and clean the insides

of

the pipes.

3) Check the exhaust gas intake flange and line, and

replace

if

corroded or cracked.

Prinled in Japan

HINSHI-H8009

4JH3E

<f,6/,p5X54

0.347

0.0062

4200

3800

1.11

1.99

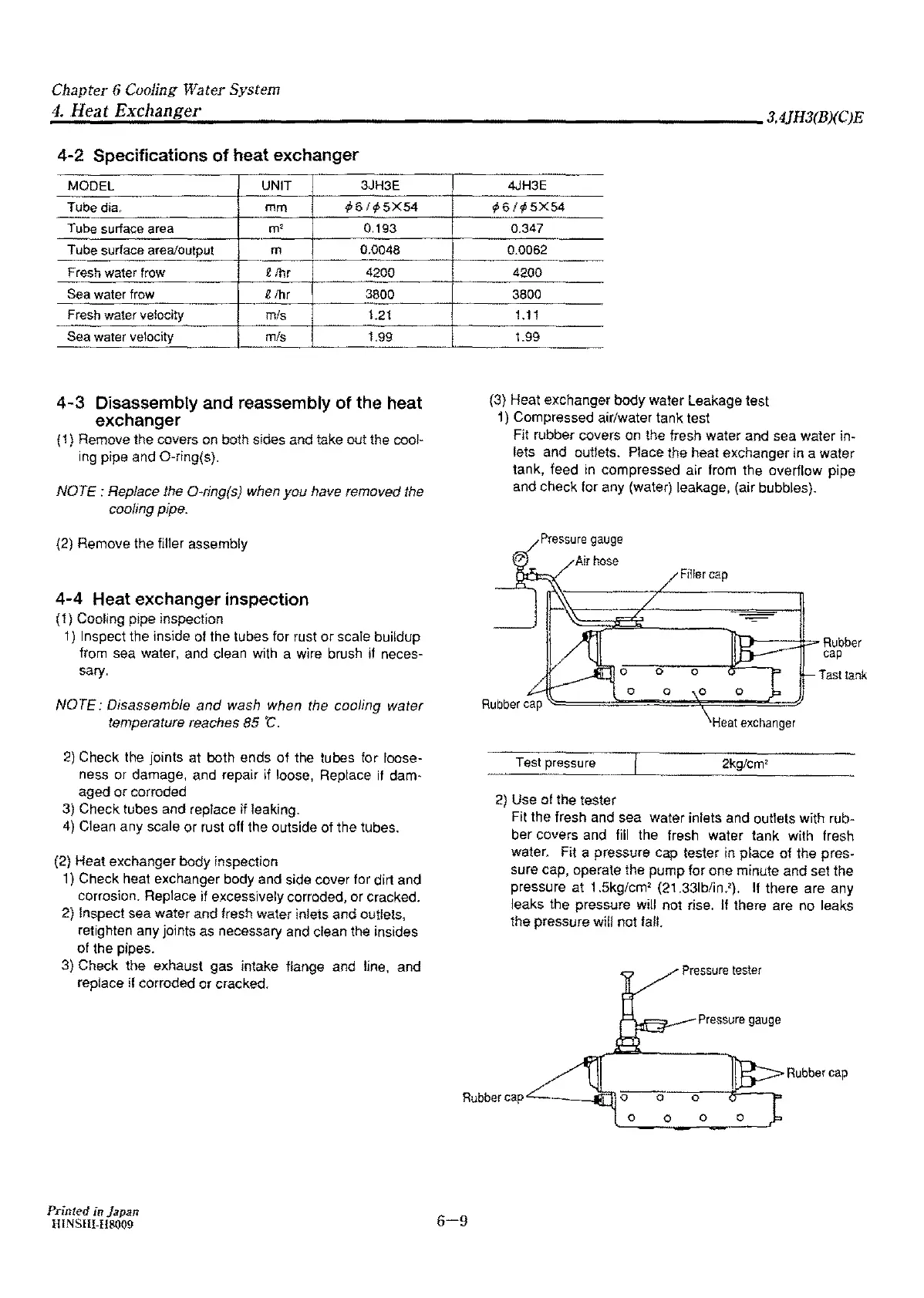

(3} Heat exchanger

body

water Leakage test

1) Compressed air/water tank test

Fit rubber covers on the fresh water and sea water in-

lets and outlets. Place the heat exchanger in

a water

tank, feed

in

compressed air from the overflow pipe

and check for any (water) leakage,

(air bubbles}.

Pressure

gauge

/Air

hose

Test pressure

2} Use of the tester

0

0

0

Filler

cap

r------,~

Rubber

cap

Tast

tank

2kg/cm

2

Fit the fresh and sea water inlets and outlets with rub-

ber covers and fill the fresh water tank with fresh

water. Fit a pressure cap tester in place of the pres-

sure cap, operate the pump for one minute and set the

pressure at 1.5kg/cm

2

(21.331b/in.l).

If

there are any

leaks the pressure will

not

rise. If there are

no

leaks

the pressure

wm

not fall.

Pressure

tester

Pressure

gauge

Rubber

cap

Rubber

cap

0

0

6-9

Loading...

Loading...