Chapter 3 Fuel Injection

Equipment

.;;4.;..

•

.;.;A;..;d.;::.j.;..u.;..st.;..m_e_n_t_o_f_F_u_el_I_n_j_ec_t_io_n_P_u_m_p

__

a_n_d_G_o_v_e_r_n_o_r

______________

3,4JH3(B)(CJE

(5)

Check control rack stroke

Make

sure

the

rack

position

is at

11.5~12.5mm

(0.4527~0.4921 in.) on the indicator scale when the

governor control lever

is

set at the maximum operating

position.

If

it

is not at this valve, change the link connecting the

governor and control rack

to

adjust it.

NOTE:

Links are availabe

in

1mm (0.0394in.) increments.

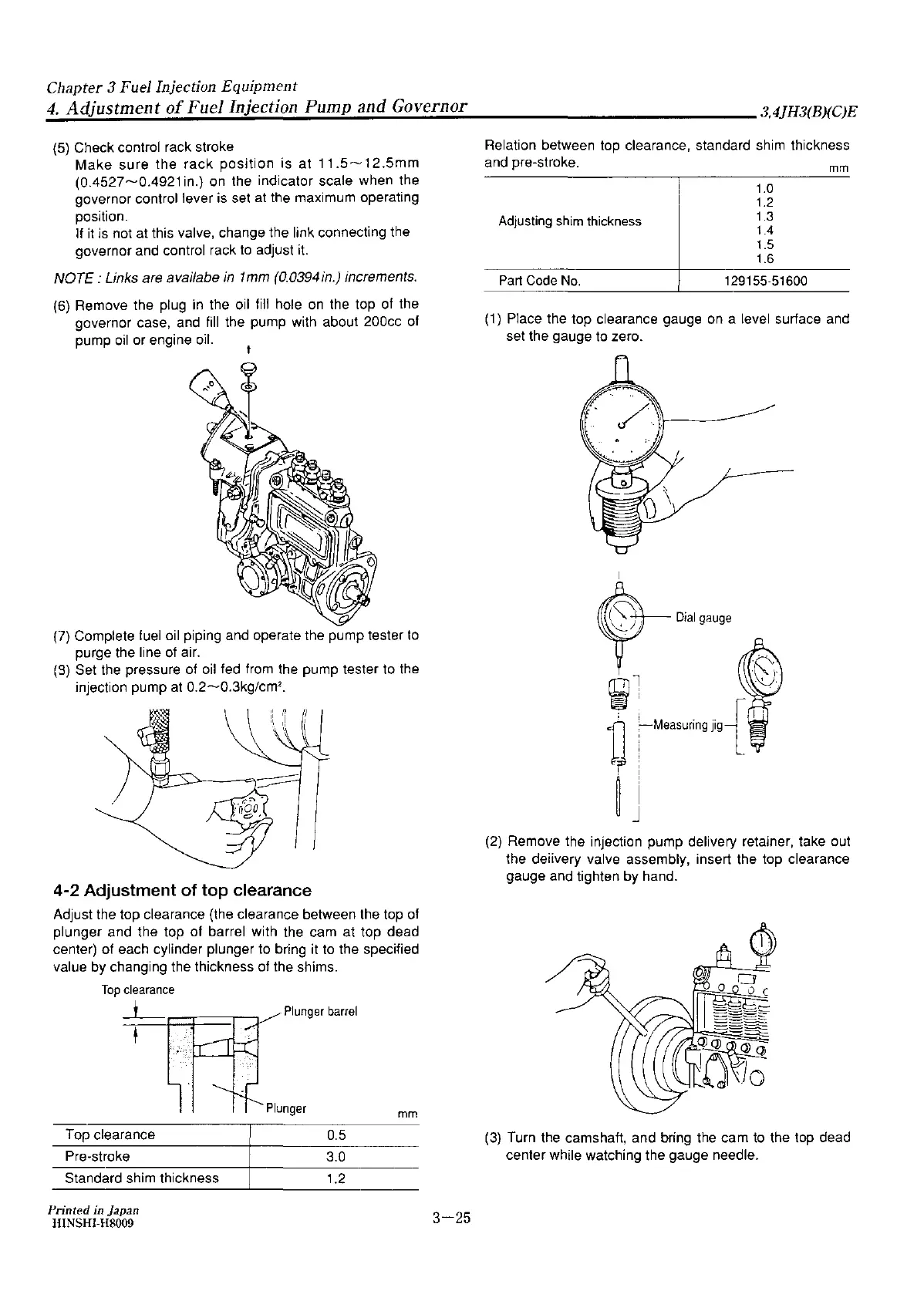

(6)

Remove the plug

in

the

oil

fill hole

on

the top of the

governor case, and fill the pump with about 200cc of

pump

oil

or engine oil.

(7)

Complete fuel

oil

piping and operate the pump tester

to

purge the line

of

air.

(S)

Set the pressure of

oil

fed from the pump tester to the

injection pump at 0.2~0.3kg/cm

2

•

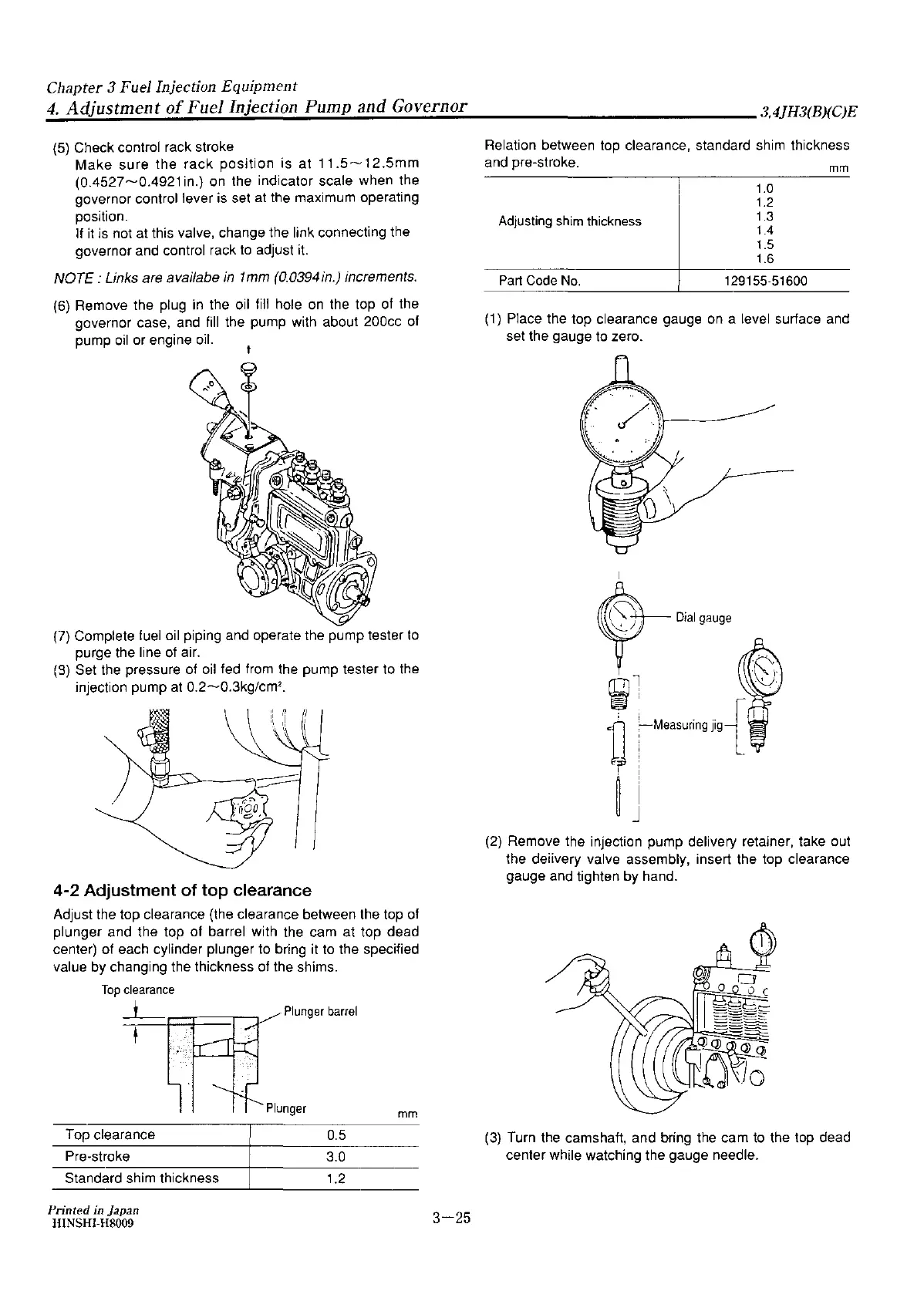

4-2 Adjustment of top clearance

Adjust the top clearance (the clearance between the top of

plunger and the top of barrel with the cam at top dead

center) of each cylinder plunger to bring it

to

the specified

value

by

changing the thickness of the shims.

Top

clearance

_l_

t

Top clearance

Pre-stroke

Standard shim thickness

Printed

in Japan

HINSHI-H8009

Plunger

barrel

mm

0.5

3.0

1.2

3-25

Relation between top clearance, standard shim thickness

and pre-stroke.

Adjusting

shim

thickness

Part Code No.

1.0

1.2

1.3

1.4

1.5

1.6

129155-51600

mm

(1)

Place the top clearance gauge

on

a level surface and

set the gauge to zero.

(2)

Remove the injection pump delivery retainer, take out

the deiivery valve assembly, insert the top clearance

gauge and tighten by hand.

(3)

Turn the camshaft, and bring

the

cam

to

the top dead

center while watching the gauge needle.

Loading...

Loading...