Chapter 9 Electrical System

_2_.

B_at_te_r.;.y

____________________________

3,4]H3(B)(C)E

2.

Battery

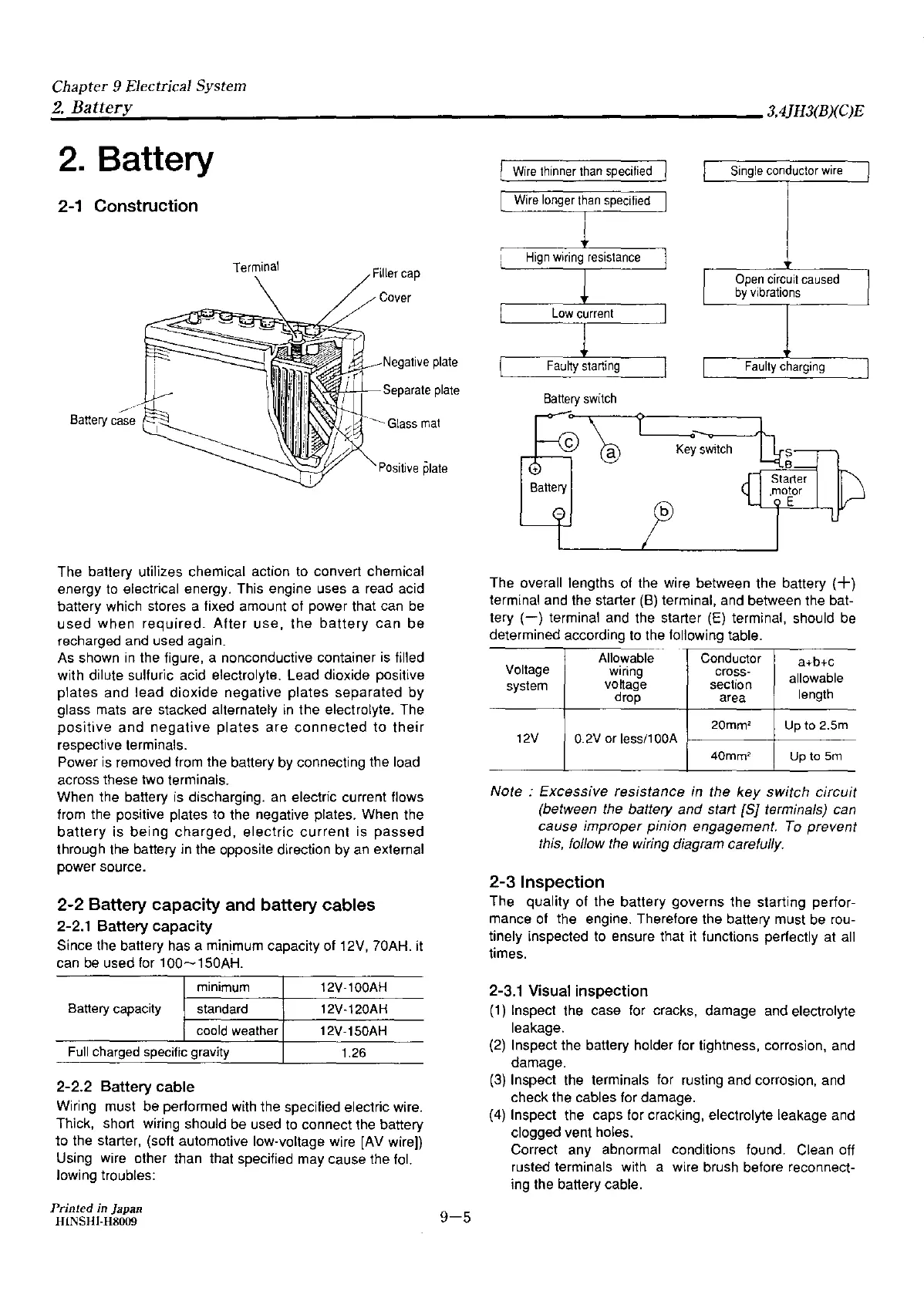

2-1 Construction

Terminal

Filler

cap

Cover

Negative

plate

,.,.,l;l-,L,___.__~

Separate

plate

Battery

c~~

Glass

mat

Positive

plate

The battery utilizes chemical action to convert chemical

energy to electrical energy. This engine uses a read acid

battery which stores a fixed amount of power that can

be

used

when

required.

After

use,

the

battery

can

be

recharged and used again.

As

shown

in

the figure, a nonconductive container

is

filled

with dilute sulfuric acid electrolyte. Lead dioxide positive

plates and lead dioxide negative plates separated by

glass mats are stacked alternately

in

the electrolyte. The

positive

and

negative

plates

are

connected

to

their

respective terminals.

Power

is

removed from the battery

by

connecting the load

across these two terminals.

When the battery

is

discharging.

an

electric current flows

from the positive plates to the negative plates. When the

battery

is

being

charged,

electric

current

is

passed

through the battery in the opposite direction

by

an

external

power source.

2-2 Battery capacity and battery cables

2-2.1 Battery capacity

Since the battery has a minimum capacity of 12V, 70AH. it

can

be

used for 100~150AH.

minimum

12V-100AH

Battery

capacity

standard

12V-120AH

coold

weather

12V-150AH

Full

charged

specific

gravity

1.26

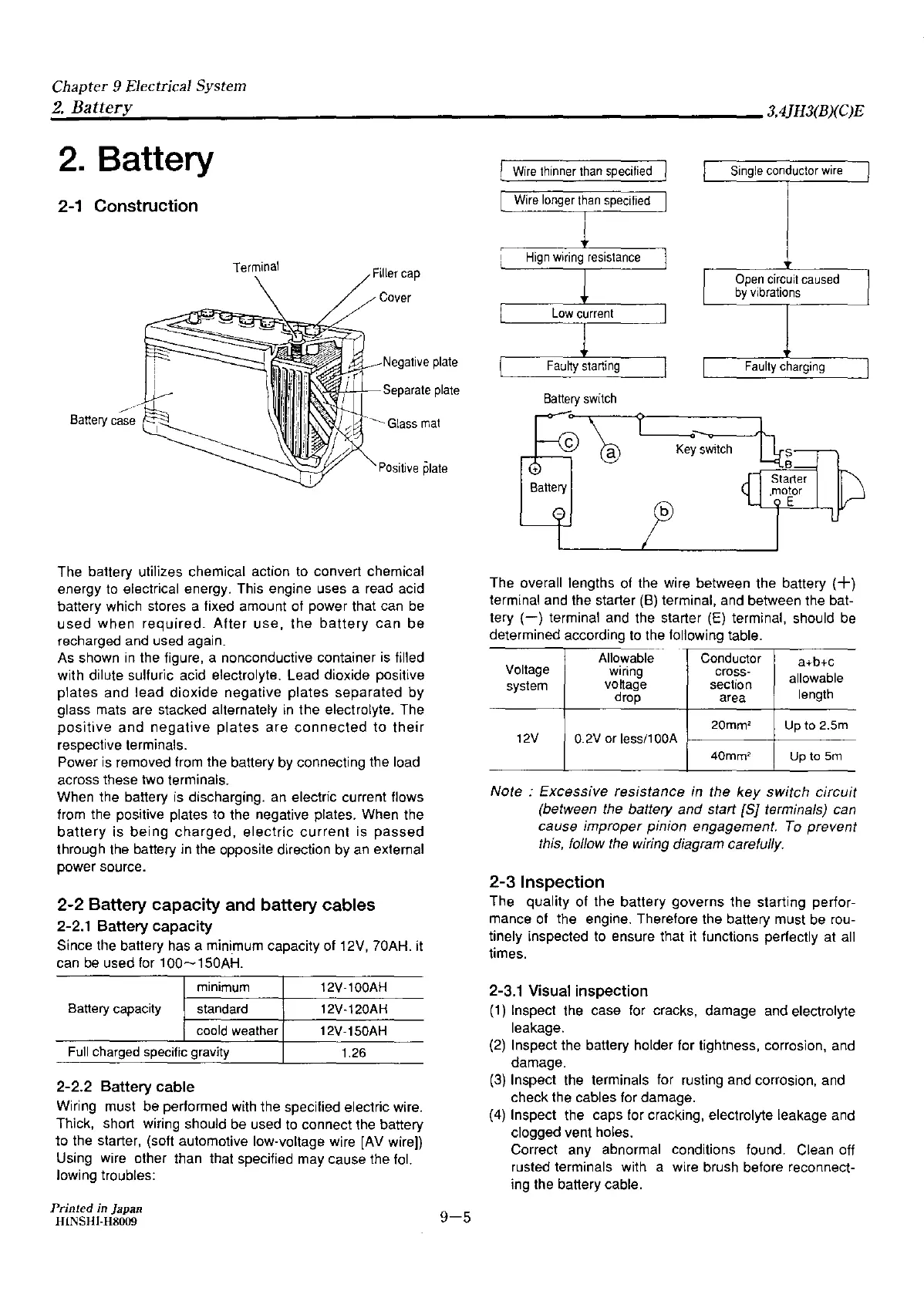

2-2.2 Battery cable

Wiring must be performed with the specified electric wire.

Thick, short wiring should

be

used to connect the battery

to !he st~rter, (soft automotive low-voltage wire

[AV

wire)}

Using wire other than that specified may cause the

fol.

lowing troubles:

Printed in Japan

H!NSHl-H8009

9-5

[

Wire

thinner

than

specified

Wire

longer

than

specified

Hign

wiring

resistance

Low

current

Faulty

starting

Ba1tery

switch

Single

conductor

wire

Open

circuit

caused

by

vibrations

Faulty

charging

The overall lengths

of

the wire between the battery

(+)

terminal and the starter (8) terminal, and between the bat-

tery

(-)

terminal and the starter

(E)

terminal, should

be

determined according to the following table.

Allowable

Conductor

a+b+c

Voltage

wiring

cross-

allowable

system

voltage

section

drop

area

length

20mm'

Up

to

2.Sm

12V

0.2V

or

less/1

ODA

40mm'

Up

to

5m

Note : Excessive resistance in the

key

switch

circuit

(between the battery and start

[SJ

terminals) can

cause improper pinion engagement.

To

prevent

this, follow the wiring diagram carefully.

2-3 Inspection

The quality of the battery governs the starting perfor-

mance of the engine. Therefore the battery must

be

rou-

tinely inspected to ensure that it functions perfectly at all

times.

2-3.1

Visual inspection

(1)

Inspect the case for cracks, damage and electrolyte

leakage.

(2)

Inspect the battery holder for tightness, corrosion, and

damage.

(3}

Inspect the terminals for rusting and corrosion, and

check the cables for damage.

(4)

Inspect the caps for cracking, electrolyte leakage and

clogged vent holes.

Correct any abnormal conditions found. Clean off

rusted terminals with a wire brush before reconnect-

ing the battery cable.

Loading...

Loading...