Chapter 3 Fuel Injection Equipment

_3_.

_D_is_a_s_se_m_bl_y.;..,

_R_e_a_ss_e_m_b_l...,y_a_n_d_I_n_s_p_ec_t_Jo_n_of_F_u_el_l_n_j_ec_t_io_n_P_u_m_p

________

3.4JH3(B)(C)E

3-2

Inspection

of

fuel injection pump

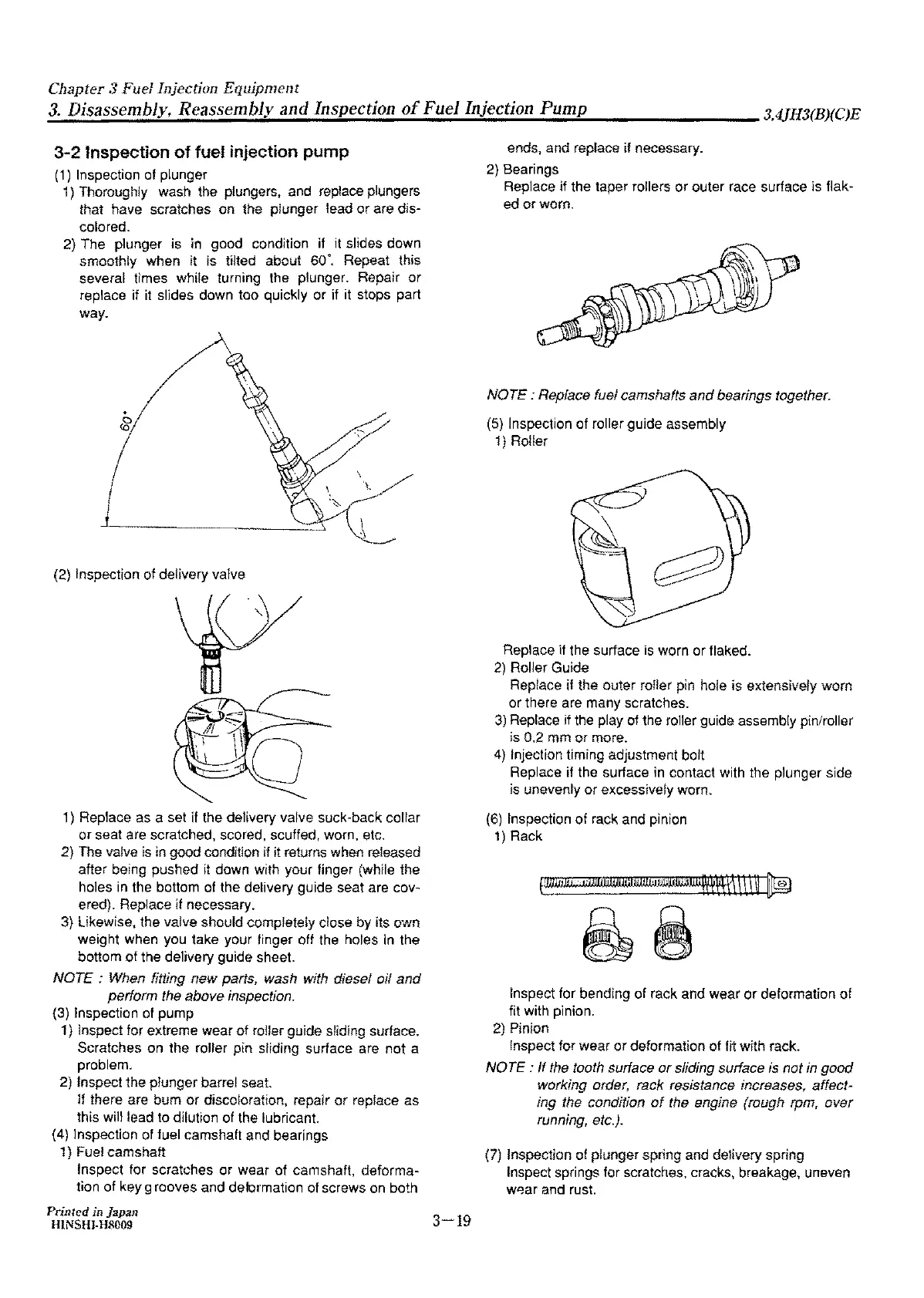

(1) Inspection of plunger

1)

Thoroughly wash the plungers, and replace plungers

that

have

scratches

on

the

plunger lead

or

are

dis-

colored.

2} The

plunger

is

in goad condition if it slides dawn

smoothly

when

it

is

tilted

about

so·.

Repeat this

several times while turning the plunger. Repair

or

replace

if

it slides down tao quickly

or

if it stops part

way.

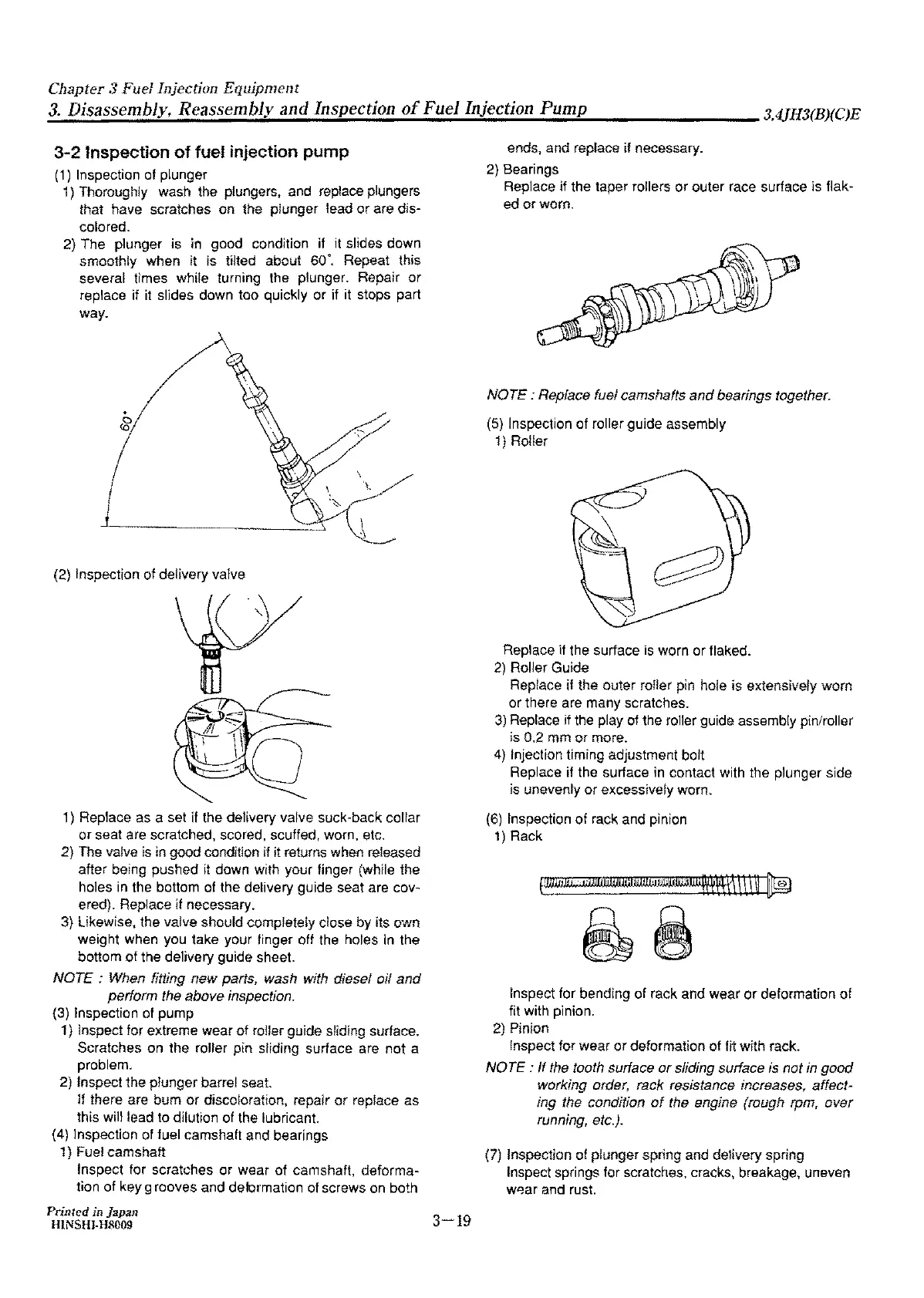

(2) Inspection

of

delivery valve

1) Replace

as

a set

1f

the

delivery valve suck-back collar

or

seat are scratched, scored, scuffed, warn, etc.

2) The valve is in good condition

if

it returns when released

after being

pushed

it

down

with your finger

(whHe

the

holes in the bottom of the delivery guide seat

are

cov-

ered). Replace

it necessary.

3}

likewise,

the

valve should completely

dose

by

its own

weight when you

take

your finger off the holes in the

bottom

of

the delivery guide sheet.

NOTE : When fitting new parts, wash with diesel oil and

perform the above inspection.

{3) Inspection of

pump

1) Inspect for extreme

wear

of

roller guide sliding surface.

Scratches

on

1he roller

pin

sliding surface are

not

a

problem.

2) Inspect the

plunger

barrel seat.

lf

there

are

bum

or

discoloration, repair

or

replace

as

this will lead to dilution of the lubricant.

{4) Inspection of fuel camshaft and bearings

1) Fuel

camshaft

Inspect for scratches

or

wear

of

camshaft,

deforma-

tion of key

grooves

and

deformation of screws on both

Printed in japan

HINSH1-H8009

3-19

ends,

and

replace

if

necessary.

2) Bearings

Replace

if

the taper rollers

or

outer race surface is flak-

ed

or

worn.

NOTE:

Replace fuel camshafts

and

bearings together.

(5)

Inspection of roller

guide

assembly

i} Roller

Replace

if

the surface is worn or flaked.

2) Roller

Guide

Replace

if

the

outer rofler pin hole is extensively worn

or

there are many scratches.

3) Replace if the play

of

the roller guide assembly pin/roller

is

0.2

mm

or

more.

4}

Injection timing adjustment bolt

Replace if the surface in contact with the plunger side

is unevenly

or

excessively worn.

(6)

Inspection

of

rack

and

pinron

1) Rack

fUiJi,Ju

,;JlllMUIWTu.WJ.ii;~\\,\~

~

~

Inspect for bending

of

rack

and

wear

or

deformation of

fit with pinion.

2) Pinion

Inspect

for wear

or

deformation

of

fit with rack.

NOTE : If

the

tooth surface or sliding surface is not

in

good

working order, rack resistance increases, affect-

ing the condition

of

the engine (rough rpm, over

running, etc.).

{7)

Inspection of

plunger

spring and delivery spring

Inspect springs for scratches. cracks, breakage, uneven

w~ar and

rust

Loading...

Loading...