Chapter 3 Fuel Injection Equipment

_3_.

_D_is_a_s_s_em_b..:ly;..;,_R_ea_s_s_e_m_b_ly

__

a_n_d_L_n_s_p_e_ct_io_n_o_f_F_u_e_l_In_'J_·e_c_t1_·0_n_P_u_m

__

p

________

3

•

4

JHS(B)(C)E

(8)

Inspection

of

oil seals

Inspect oil seals to see if they are burred or scratched.

(9)

Inspection of roller guide stop

Inspect the side of

the

tip, replace if excessively worn.

(10)

Inspection of O-rings

Inspect and replace

if

they are burred or cracked.

3-3

Reassembly of fuel injection pump

Preparation

After inspection, put all parts

in

order and clean.

See Inspection of Fuel Pump for inspection procedure.

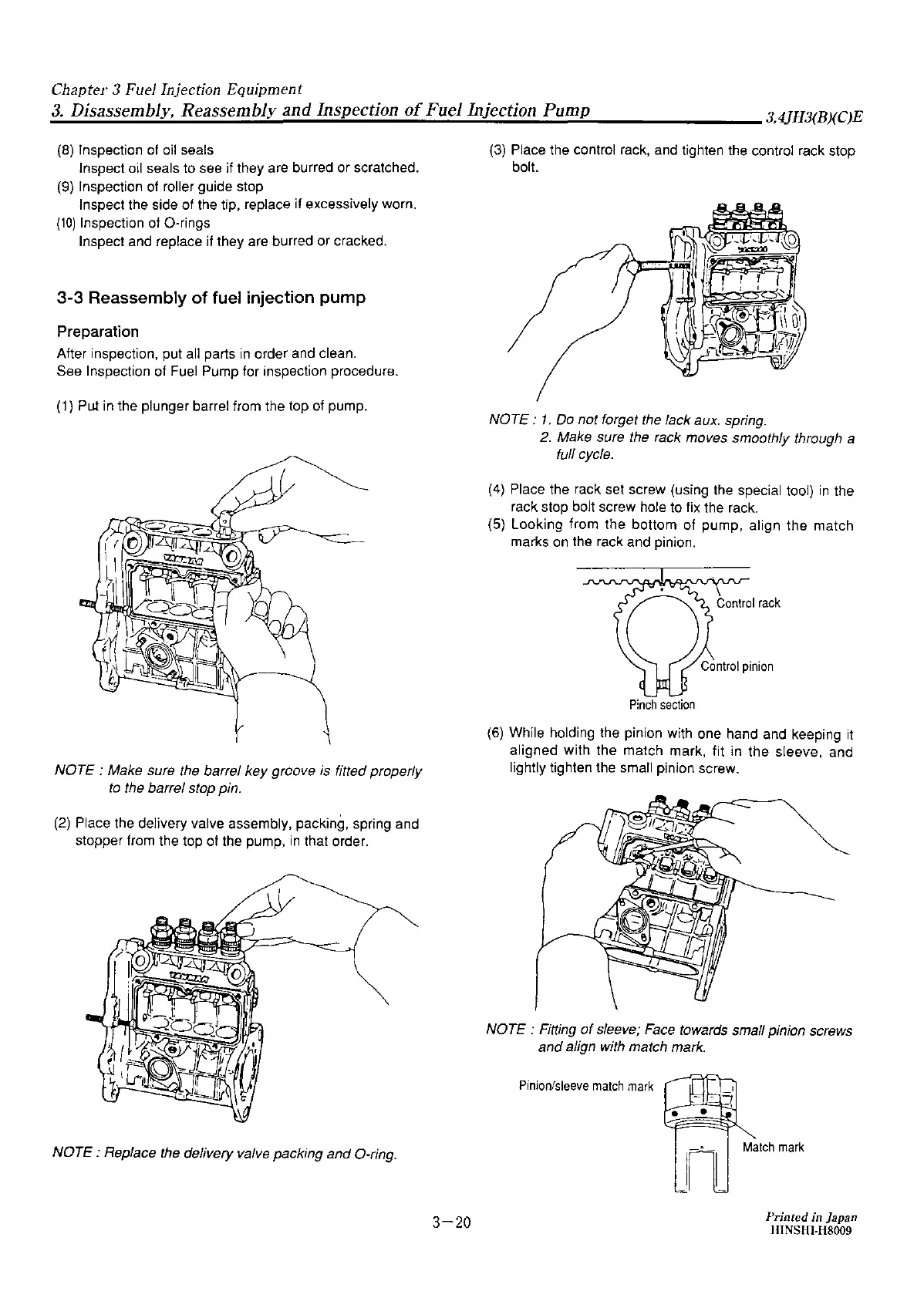

(1)

Pu.t

in

the plunger barrel from the top

of

pump.

NOTE:

Make sure the barrel key groove

is

fitted properly

to

the barrel stop pin.

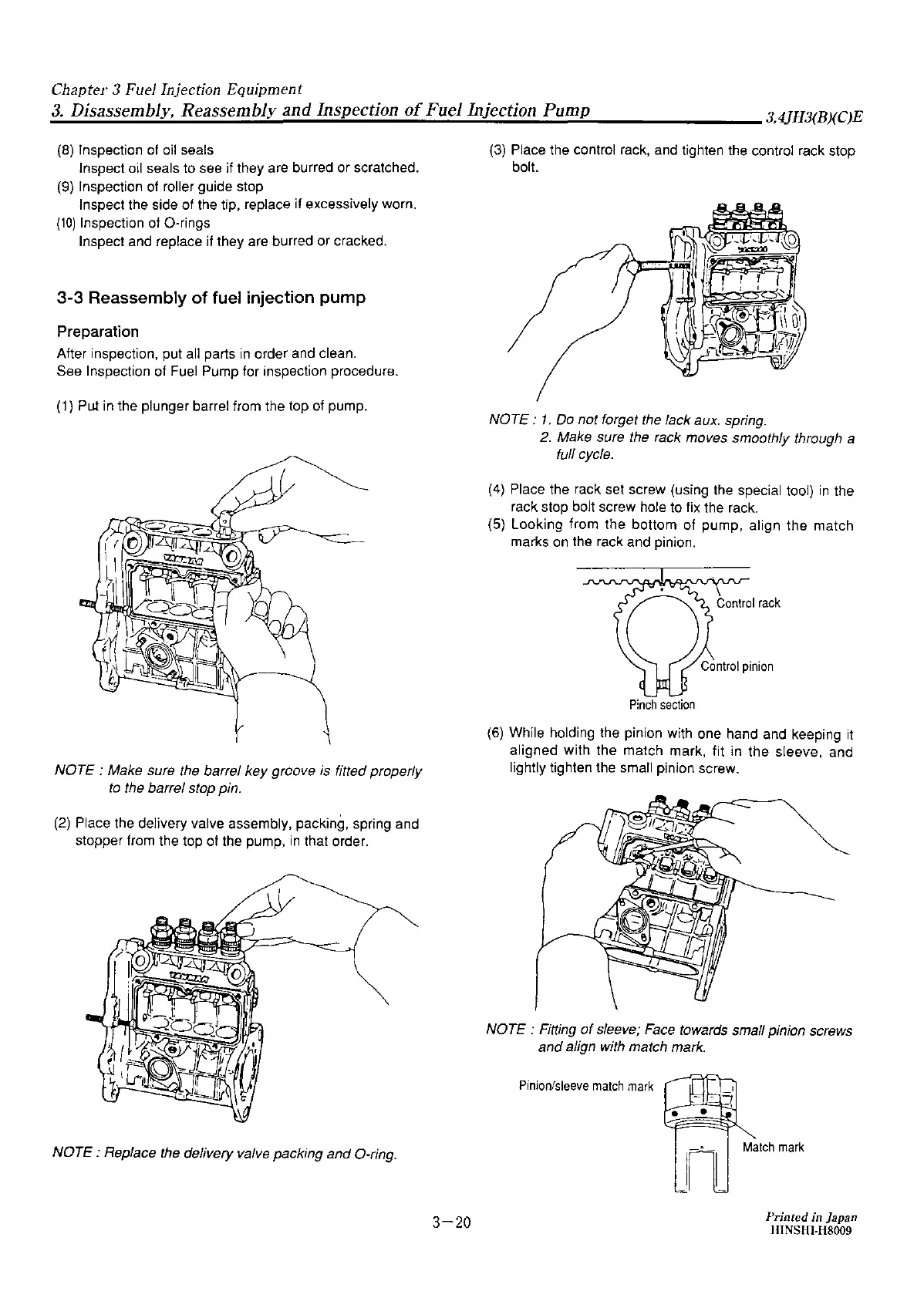

(2)

Place the delivery valve assembly, packing, spring and

stopper from the top of the pump,

in

that order.

NOTE : Replace the delivery valve packing and 0-ring.

3-20

(3)

Place the control rack, and tighten

the

control rack stop

bolt.

NOTE:

1.

Do

not forget the lack aux. spring.

2.

Make sure the rack moves smoothly through a

full cycle.

(4)

Place the rack set screw (using

the

special tool)

in

the

rack stop bolt screw hole to

fix

the rack.

(5) Looking from the bottom of pump, align the match

marks

on

the rack and pinion.

P:nch

section

(6)

While holding the pinion with one hand and keeping

it

aligned with the match mark, fit in the sleeve, and

lightly tighten the small pinion screw.

NOTE : Fitting

of

sleeve; Face towards small pinion screws

and

align with match mark.

Pinion/sleeve

match

mark

Printed in Japan

HINSHI-H8009

Loading...

Loading...