Chapter 2 Basic Engine

_8._F_1..;..y_w_h_e_e_l

_an_d_H_o_u_s1_·n_g

_______________________

3

,

41

H

3

(B)(C)E

8.

Flywheel and Housing

The function of the flywheel is through inertia, to rotate the

crankshaft in a uniform and smooth manner by absorbing

the turning force created during the combustion stroke of

the engine, and by compensating for the decrease

in

turn-

ing force during the other strokes.

The flywheel is mounted and secured by 6 bolts on the

crankshaft end

at

the opposite end to the gear case;

it

is

covered by the mounting flange (flywheel housing) which

is bolted to the cylinder block.

the fitting surface for the damper disc

is

on

the crankshaft

side

of

the

flywheel.

The

rotation of the

crankshaft

is

transmitted

through

this

disc

to the

input

shaft of

the

reduction and reversing gear. The reduction and reversing

gear is fitted to the mounting flange.

The flywheel's unba!anced force on the shaft center must

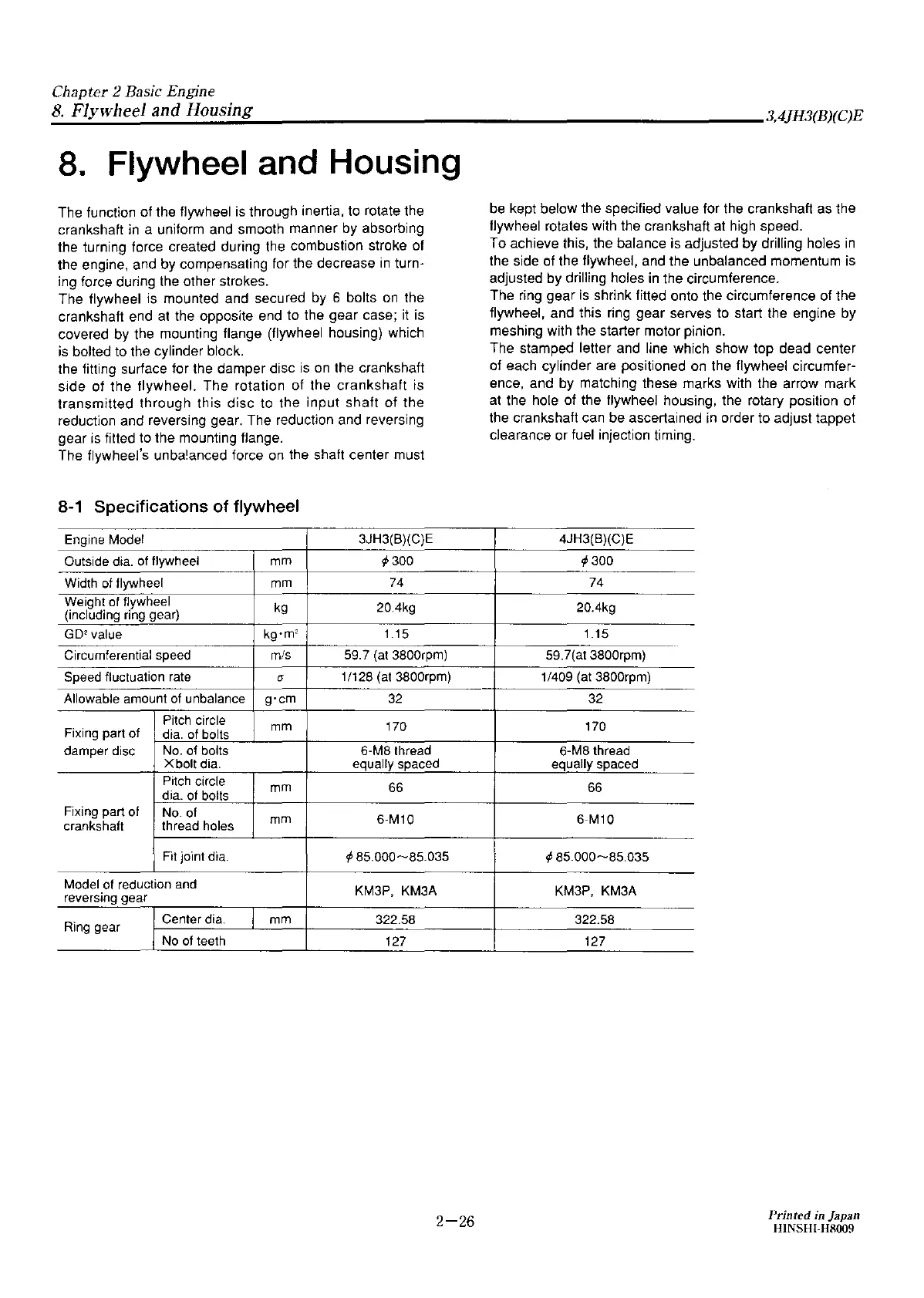

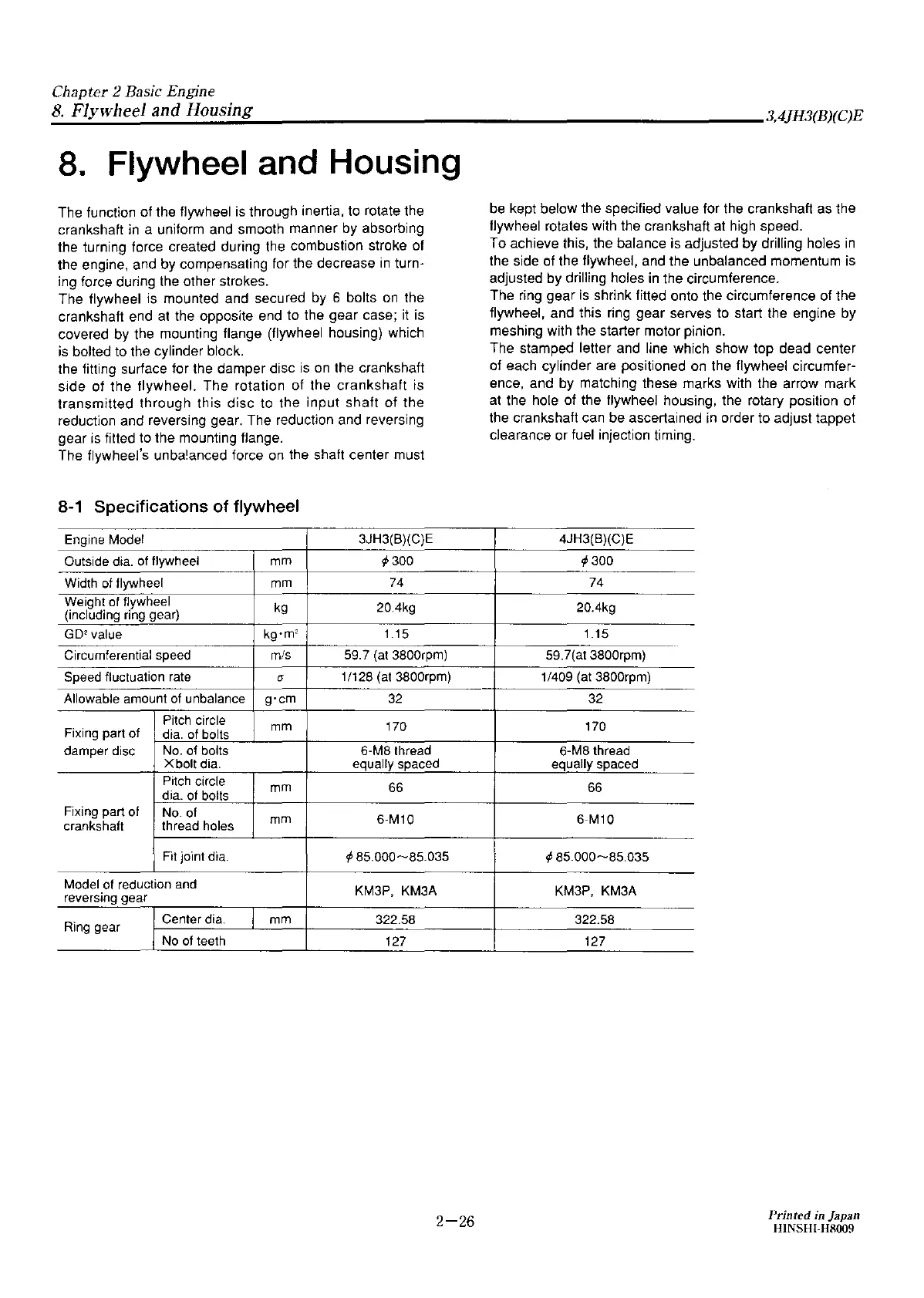

8-1

Specifications of flywheel

Engine

Model

3JH3(B)(C)E

Outside

dia.

of

flywheel

mm

,f

300

Width

of

flywheel

mm

74

Weight

of

flywheel

kg

20.4kg

(including

ring

gear)

GD

2

value kg·m'

1.15

Circumferential speed

m/s

59.

7 (al 3800rpm)

Speed

fluctuation

rate

(Y

1/128

(al 3800rpm)

Allowable amount

of

unbalance g·cm

32

Pitch

circle

mm

170

Fixing

part of

dia.

of

bolts

damper disc

No.

of

bolts

6-M8 thread

Xbolt

dia.

equally spaced

Pitch

circle

mm

66

dia.

of

bolts

Fixing part

of

No.

of

mm

6-M10

crankshaft thread holes

Fit

jo·1nt

dia.

¢ 85.000~85.035

Model

of

reduction

and

KM3P, KM3A

reversing gear

Ring

gear

Center

dia.

mm

322.58

No

of

teeth

127

2-26

be kept below the specified value for the crankshaft

as

the

flywheel rotates with the crankshaft at high speed.

To achieve this, the balance is adjusted

by

drilling holes

in

the side of the flywheel, and the unbalanced momentum is

adjusted by drilling holes in the circumference.

The ring

gear

is shrink fitted onto the circumference of the

flywheel, and this ring gear serves to start the engine by

meshing with the starter motor pinion.

The stamped letter and line which show top dead center

of each cylinder are positioned on the flywheel circumfer-

ence, and by matching these marks with the arrow mark

at the hole of the flywheel housing, the rotary position of

the crankshaft can be ascertained in order to adjust tappet

clearance or fuel injection timing.

4JH3(B)(C)E

¢ 300

74

20.4kg

1.15

59.7(at 3800rpm)

1/409

(at

3800rpm)

32

170

6-M8 thread

equally spaced

66

6-M10

¢ 85.000~85.035

KM3P, KM3A

322.58

127

Printed in Japan

HINSHI-H8009

Loading...

Loading...