Chapter 2 Basic Engine

_s_.

c_ra_n_k_s_h_ali_t_a_n_d_M_a_in_B_e_a_n_·n_g

_____________________

3

.4JHJ(B)(C)E

(4)

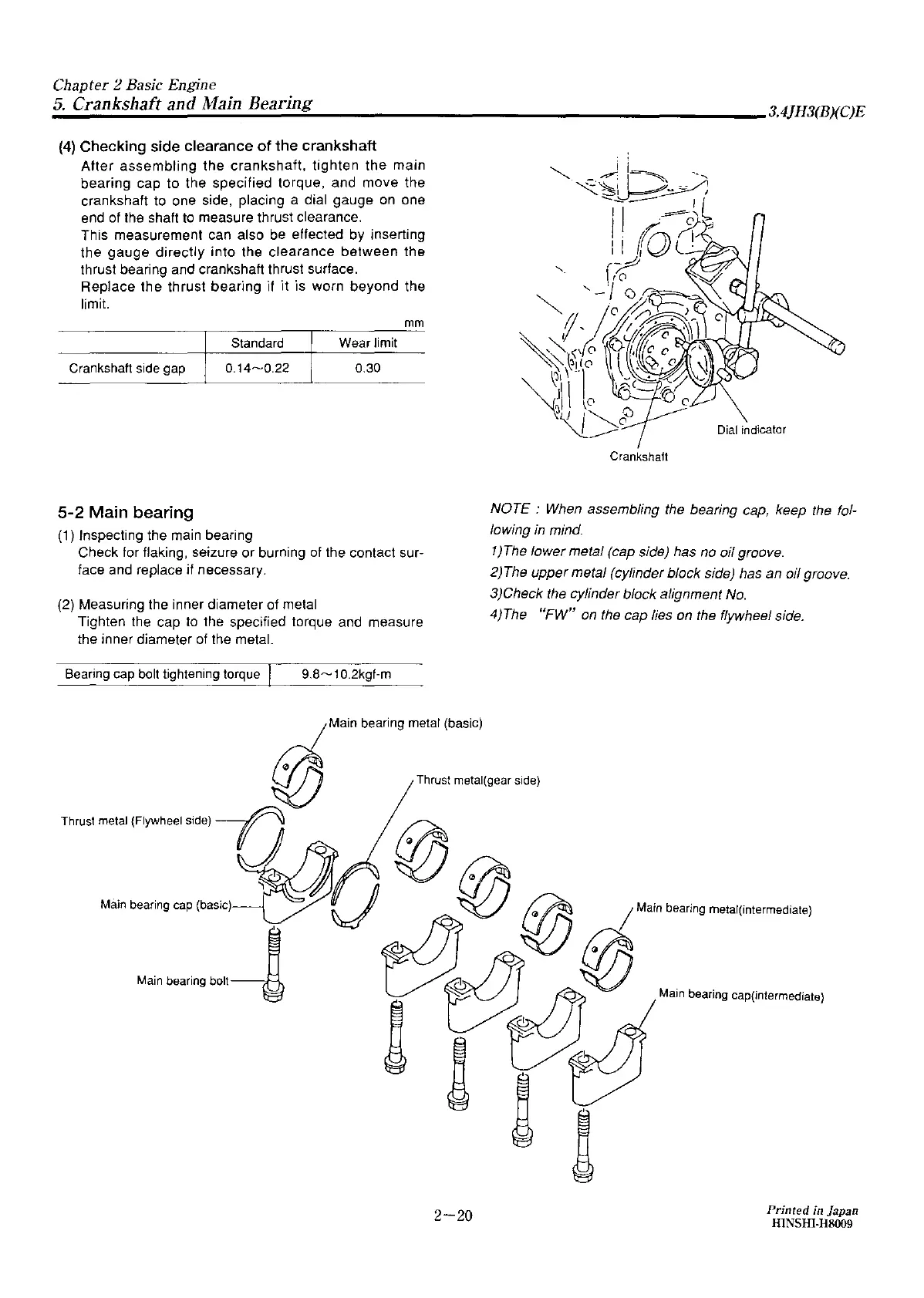

Checking side clearance

of

the

crankshaft

Atter

assembling

the

crankshaft, tighten

the

main

bearing cap to the specified torque, and move the

crankshaft to one side, placing a dial gauge

on

one

end

of

the

shaft

to

measure thrust clearance.

This measurement can also

be

effected by inserting

the gauge directly into the clearance between the

thrust bearing and crankshaft thrust surface.

Replace

the

th

rust bearing if it

·1s

worn beyond the

limit.

mm

Standard

Wear

limit

Crankshaft

side

gap

0.14~0.22

0.30

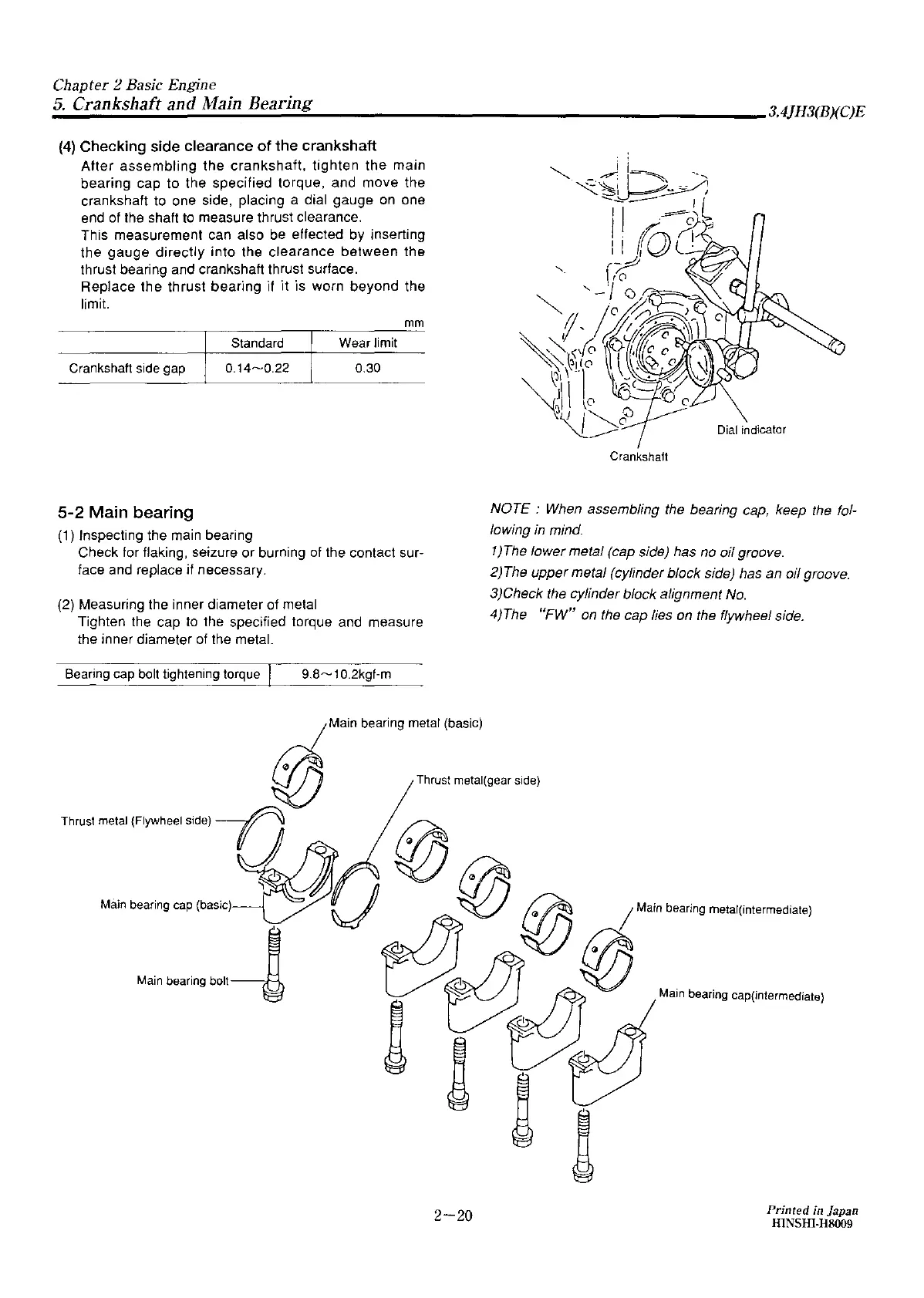

5-2 Main bearing

(1)

Inspecting the main bearing

Check for flaking, seizure or burning

of

the contact sur-

face and replace if necessary.

(2)

Measuring the inner diameter of metal

Tighten the cap

to

the specified torque and measure

the inner diameter

of

the metal.

Bearing

cap

bolt

tightening

torque

]

9.8~10.2kgf-m

Dial indicator

Crankshaft

NOTE :

When

assembling the bearing cap, keep the fol-

lowing

in

mind.

1 )The lower metal (cap side) has no oil groove.

2)The upper metal (cylinder block side) has an oil groove.

3)Check

the

cylinder block alignment

No.

4)The

"FW"

on

the cap

fies

on the flywheel side.

ci

Ma;n

bea,mg

metal

(bas;cJ

f0

Thrust

m,tal(ge"

s,da)

Thrust metal (Flywheel side)

Main bearing cap {basic)

Ma;, b,a,;og

bolt--!

2-20

Main bearing cap(intermediate}

Printed in Japan

HINSHI-H8009

Loading...

Loading...