Chapter 2 Basic Engine

.;;.5;_.

C.;;..;.;ra;;,;;,n;;,;;,k;,;;,s;;,;;,ha:;.fi..;.t..;;a;.;.n..;.d..;.A,_1.;.;.a1;.;.·n_B_e...;,a_r_in_g;;..._,

____________________

3,4JH3(B)(C)E

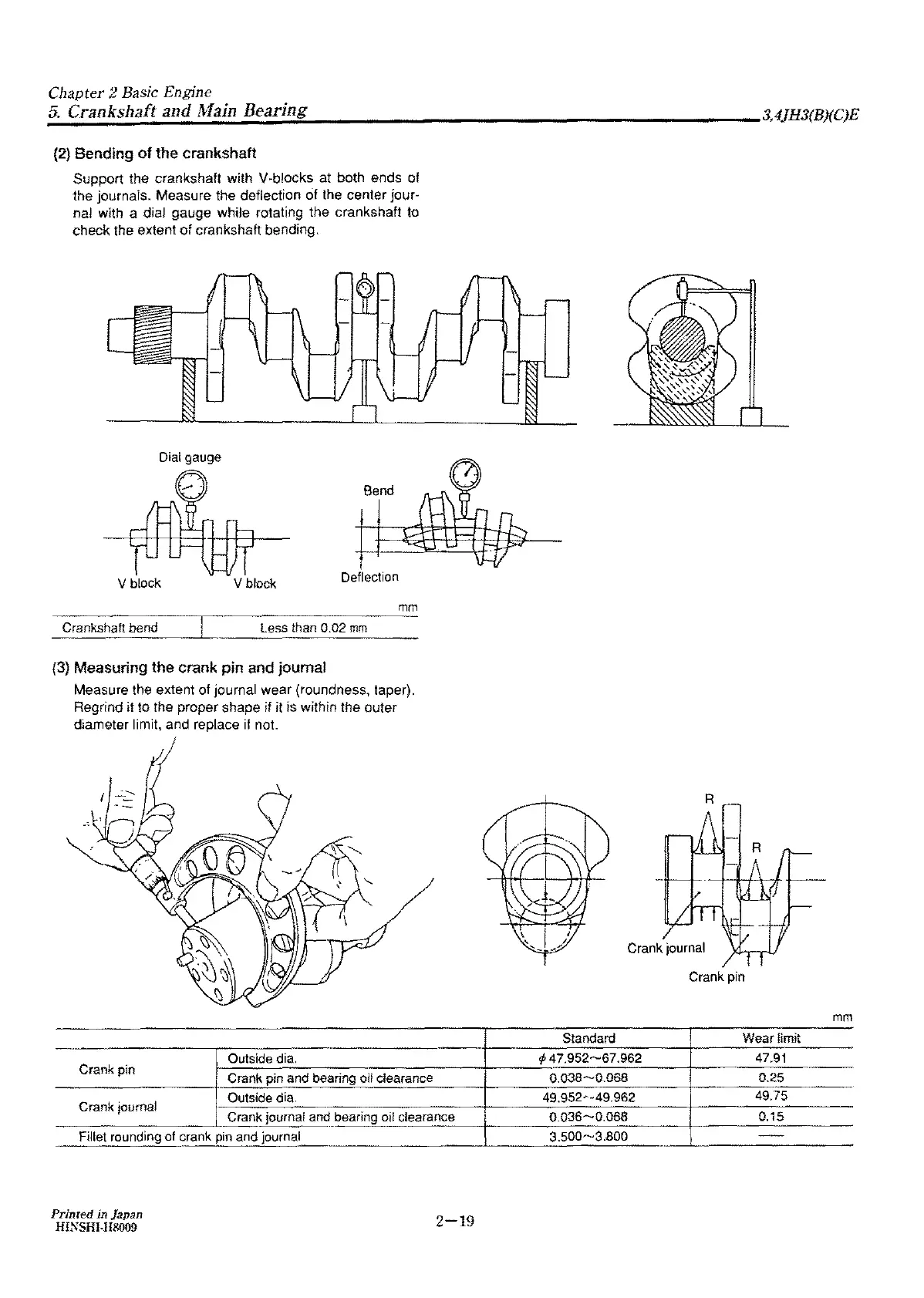

(2)

Bending

of

the

crankshaft

Support the crankshaft with V •blocks at both ends

of

the journals, Measure the deflection

of

the center jour-

nal with a dial gauge while rotating the crankshaft to

check the extent

of

crankshaft bending.

Dtal gauge

Bend

Deflection

mm

Crankshaft bend

Less

than

0.02

mm

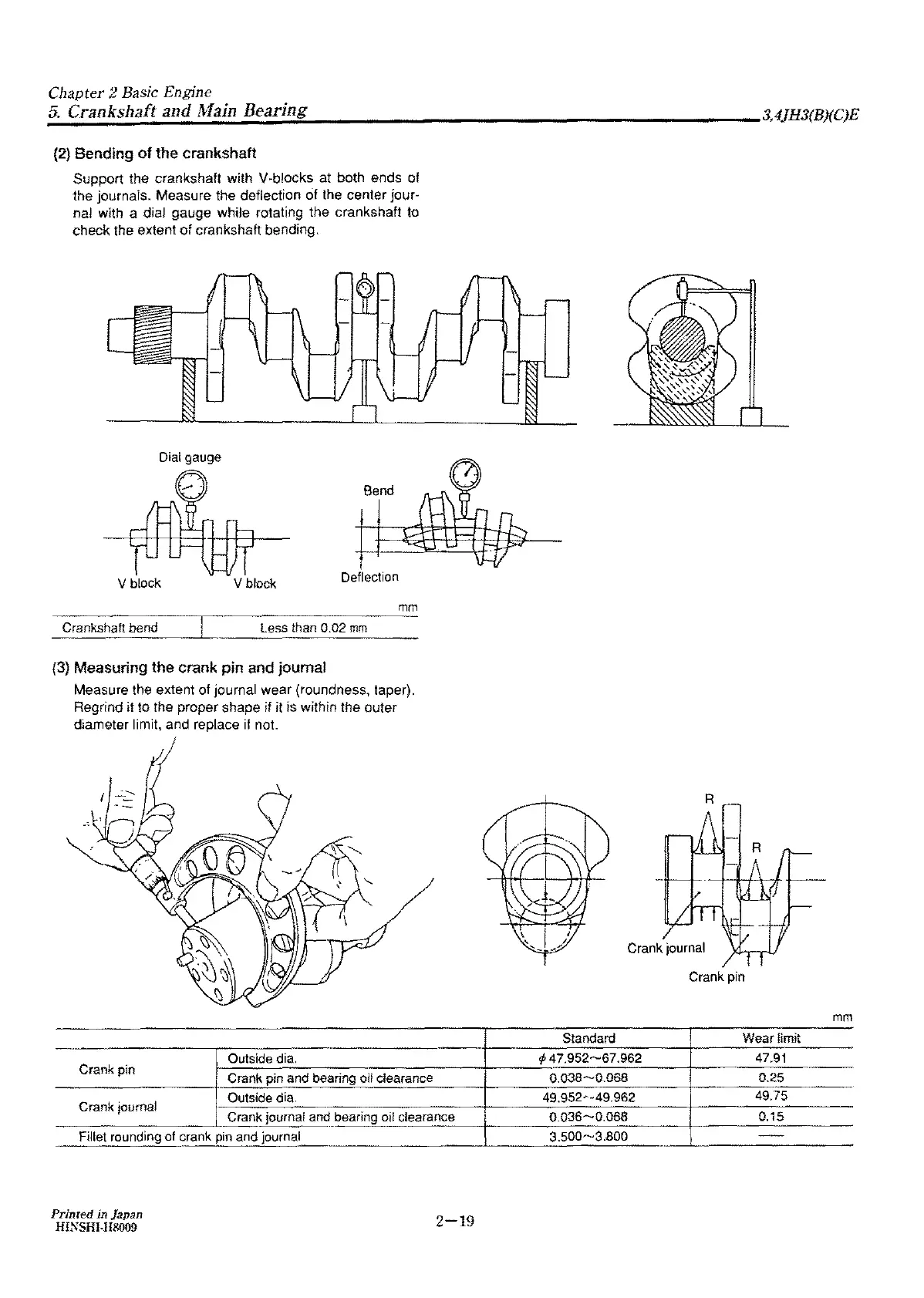

(3)

Measuring

the

crank pin and journal

Measure the extent of journal wear (roundness, taper).

Regrind

it to the proper shape if it is within the outer

diameter limit, and replace

if

not.

I

Crank pin

Outside dia,

Crank pin and bearing oil clearance

Outside dia,

Crank journal

Crank journal and bearing

oil clearance

Fillet rounding of crank pin and journal

Printed

in

Japan

HINSHI-H!\009

2-19

Crank pin

mm

Standard

Wear

limit

f

47.952~67.962

47.91

0.038~0.068

0.25

49.952~-49.962

49.75

0.036~0.068

0,15

3.5D0~3.8D0

~-

Loading...

Loading...