Chapter 3 Fuel Injection Equipment

~6::._.

!:.F.!!u~el~l~n~je~c:.!;t1~·0:!!n~N,.:.:o~z~z~le;;_

_______________________

3,4JH3(B)(C)E

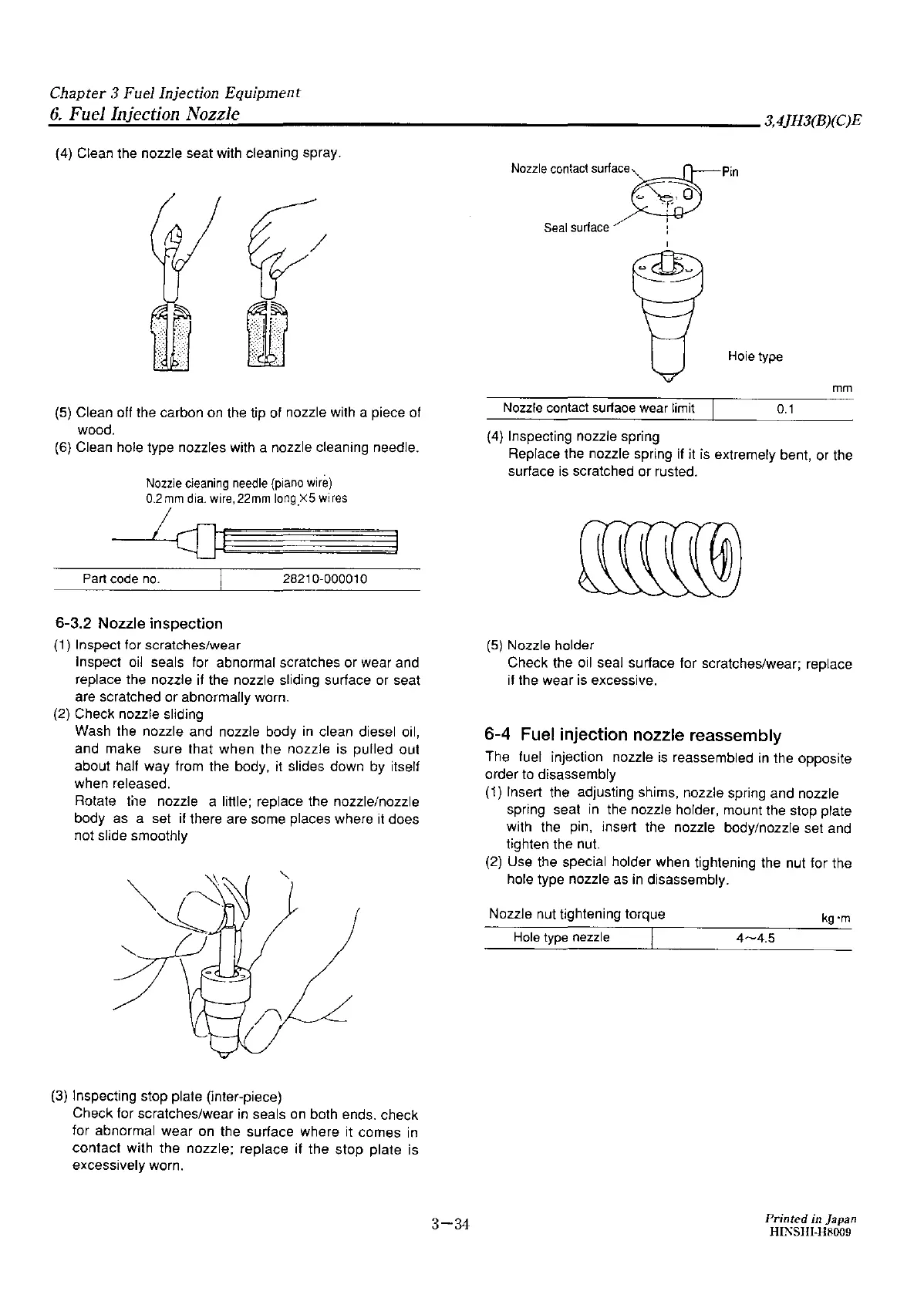

(4) Clean the nozzle seat with cleaning spray.

(5) Clean off the carbon

on

the tip of nozzle with a piece of

wood.

(6) Clean hole type nozzles with a nozzle cleaning needle.

Nozzle

deaning

needle

(piano

wire)

0.2

mm

dia.

wire,

22mm

long.XS

wires

---'--ii

cQi

Part

code

no.

6-3.2 Nozzle inspection

(1) Inspect for scratches/wear

2821 0-00001 0

Inspect oil seals for abnormal scratches or wear and

replace the nozzle if the nozzle sliding surface or seat

are scratched or abnormally

worn.

(2) Check nozzle sliding

Wash the nozzle and nozzle body

in

clean diesel oil,

and make sure that when the nozzle is pulled out

about half way from the body, it slides down by itself

when released.

Rotate Irie nozzle a little; replace the nozzle/nozzle

body as a set ii there are some places where

it

does

not slide smoothly

(3) Inspecting stop plate (inter-piece)

Check for scratches/wear

in

seals

on

both ends. check

for abnormal wear on the surface where it comes

in

contact with the nozzle; replace if the stop plate is

excessively worn.

3-34

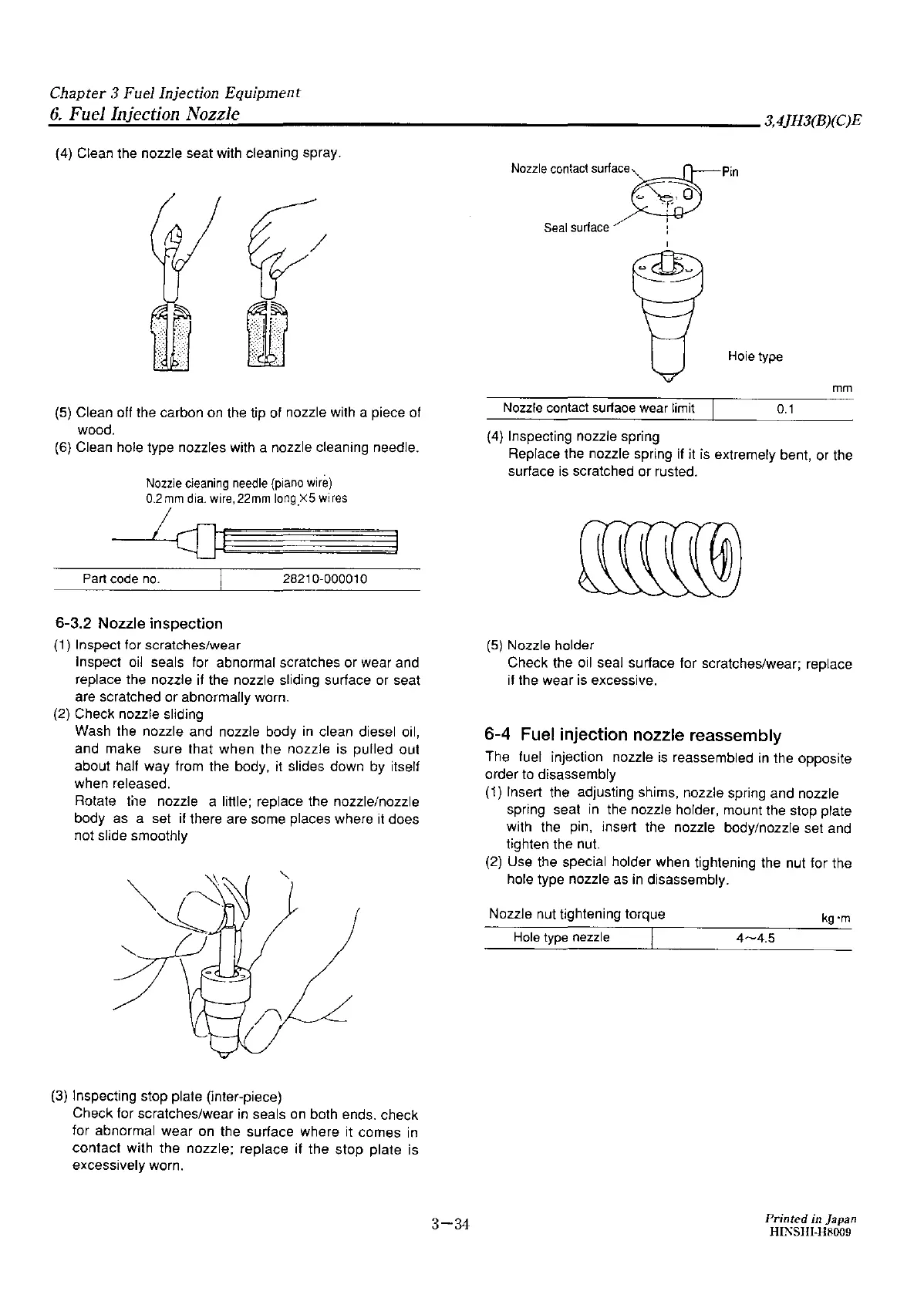

Nozzle

contact

surfa~e

Pin

<->

' (J

I

Sealsurtace

:

Hoie

type

mm

Nozzle

contact

surfaoe

wear

limit

0.1

(4) Inspecting nozzle spring

Replace the nozzle spring if it is extremely bent, or the

surface is scratched or rusted.

(5)

Nozzle holder

Check the oil seal surface for scratches/wear; replace

if the wear is excessive.

6-4 Fuel injection nozzle reassembly

The fuel injection nozzle is reassembled

in

the opposite

order to disassembly

(1)

Insert the adjusting shims, nozzle spring and nozzle

spring seat

in

the nozzle holder, mount the stop plate

with the pin, insert the nozzle body/nozzle set and

tighten the nut.

(2)

Use the special holder when tightening the nut for the

hole type nozzle as

in

disassembly.

Nozzle nut tightening torque

Hole

type

nezzle

kg·m

4~4.5

Printed

in Japan

HI!XSHI-H8009

Loading...

Loading...