Chapter 9 Electrical

System

.;;..3·;...S

__

t_a.;.r.;;.;te_r.;M..;.;..o.;.;;to_r

__________________________

3,4]H3(B)(C)E

3-7 Reassembly

Reassembly is

in

the reverse order of disassembly, how-

ever please note the following points.

1. Tightening Torques : Refer to page 4 of the referece

materials for the tightening

torques of particular screws.

2. The Places to Apply Grease :

(D----The

moving parts of shift lever.

(2)-T--The sliding suriace of magnetic switch plunger.

l--The

sliding surface of pinion.

@----The

tooth of Internal

Gear

and Planet Gear.

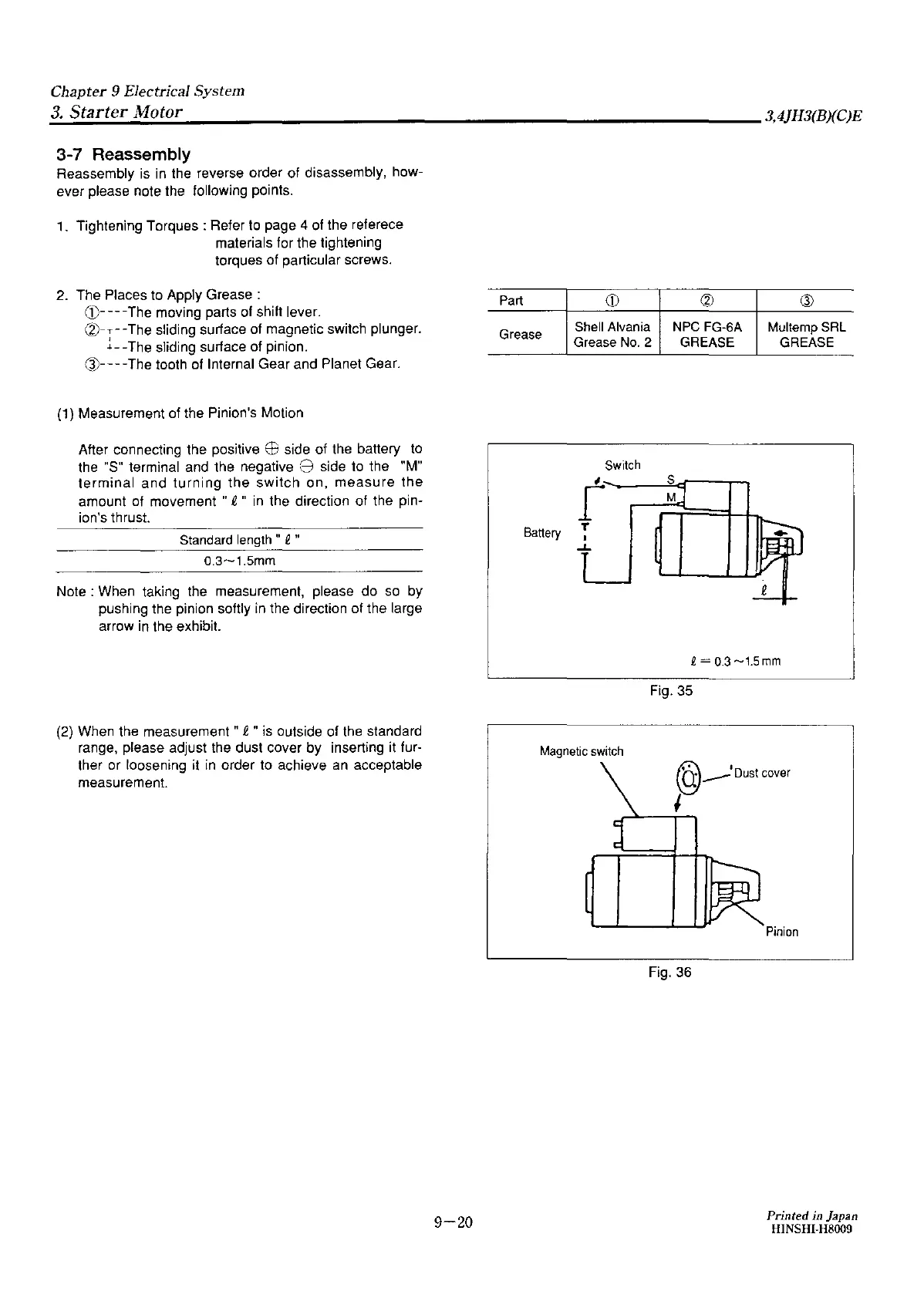

(1) Measurement of the Pinion's Motion

After connecting the positive

EB

side of the battery to

the "S" terminal and the negative

8 side to the "M"

terminal

and

turning

the

switch

on,

measure

the

amount of movement

"R,

" in the direction

of

the pin-

ion's thrust.

Standard length "

2 "

0.3~1.5mm

Note:

When taking the measurement, please do so by

pushing the pinion softly in the direction of the large

arrow in the exhibit.

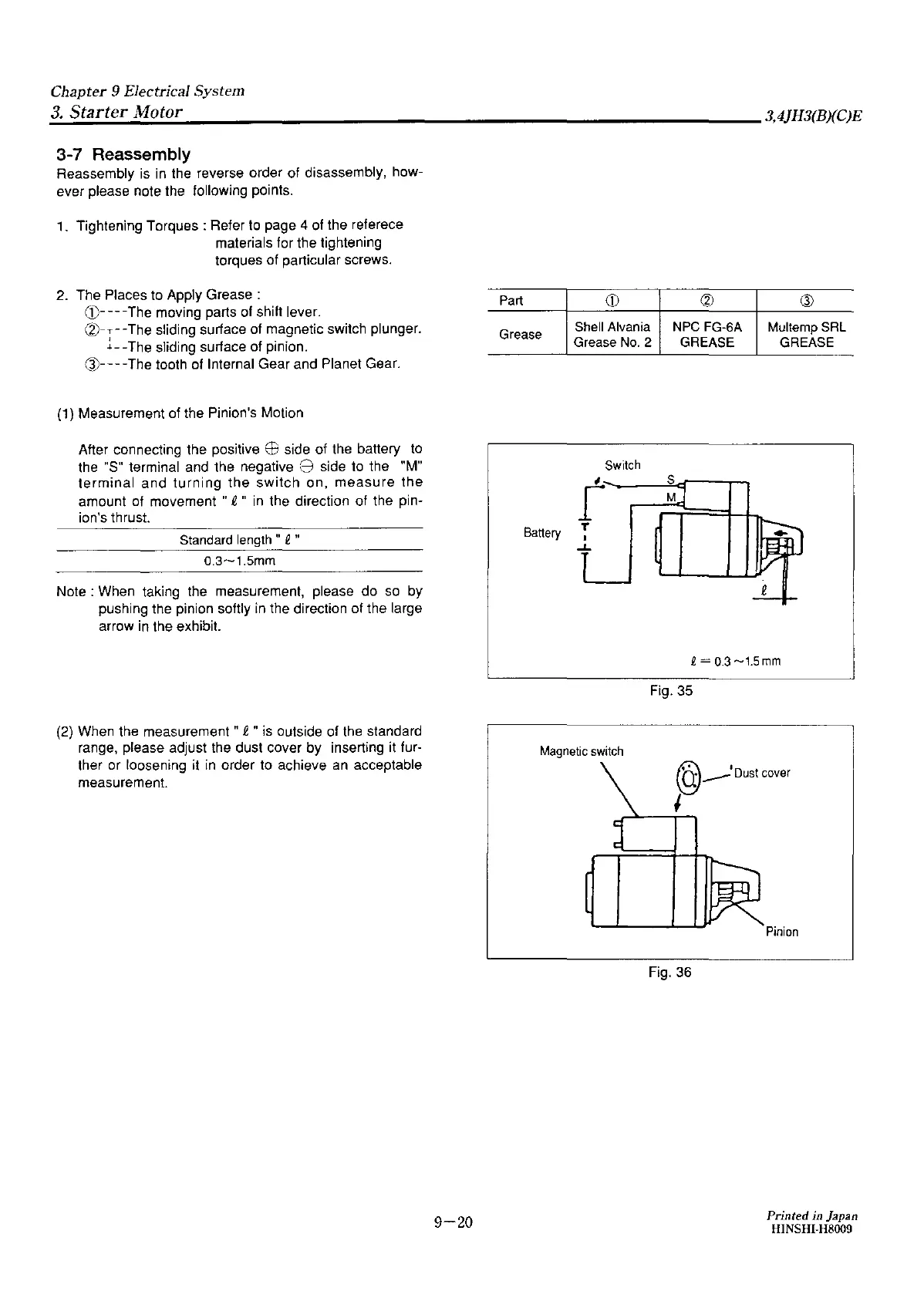

(2) When the measurement "

R,

" is outside of the standard

range, please adjust the dust cover

by

inserting it fur-

ther

or

loosening it in order to achieve an acceptable

measurement.

9-20

Part

(D

(2)

Q)

Grease

Shell Alvania NPC FG-6A

Multemp SRL

Grease No. 2 GREASE GREASE

Switch

t

s

M

Battery

T

J

..L

2

Q =

0.3

~1.5

mm

Fig. 35

Magnetic switch

@--•Dustcover

I

Fig. 36

Pinion

Printed in Japan

HINSHI-H8009

Loading...

Loading...